Manufacturers Index - C. B. Morse

C. B. Morse

Rhinebeck, NY, U.S.A.

Manufacturer Class:

Wood Working Machinery

Last Modified: Oct 1 2010 2:01PM by Jeff_Joslin

If you have information to add to this entry, please

contact the Site Historian.

|

Cyrus B. Morse, an engineer and the operator of a sash, blind, and door factory, was granted 1855 patents for a planer-matcher and a molder. He was well-timed to take advantage of the explosion in demand for planers and matchers that followed the expiry of the Woodworth planer patent in 1856. Although Morse received some early good reviews of his machines, we have not found any direct evidence that he manufactured them in any quantity.

From the "Report on the 1855 Fair of the American Institute"

In later years, Morse seemed to have two specialties: crucible steel and yarn-spinning machinery, though he continued to make other machinery (what kind is unknown). He operated under his own name, plus Union Steel and Iron Works until 1880. In that year he moved to New York City and established Morse's Novelty Works. This business survived until at least 1888.

Information Sources

- The 1848-01-01 issue of Scientific American has an illustrated article on a new device for attaching bed rails to the posts. The inventor was C. B. Morse of Rhinebeck, who was applying for a patent through Munn & Co. So far as we can tell, no patent was ever issued.

- The 1851-11-29 issue of Scientific American has the following brief writeup:

Improved Machine for Cutting Sash and Mouldings. Mr. C. B. Morse, of Rhinebeck, Dutchess Co., N. Y., has invented some good improvements on machinery for making sash and mouldings, for which he has taken measures to secure a patent. The cutter is formed of two circular plates placed on the same shaft, and so arranged that the said plates may be set at a greater or less distance apart as desired in order to cut different mouldings. The cutters are adjusted by set screws. He also employs shields which prevent the feed rollers from forcing the stuff against the cutters, when acting upon the end of the stuff to be cut out. The shields also prevent the rollers from loosening the grains of the wood and also from forcing out pieces from the end of the rough material.

No such patent was ever issued.

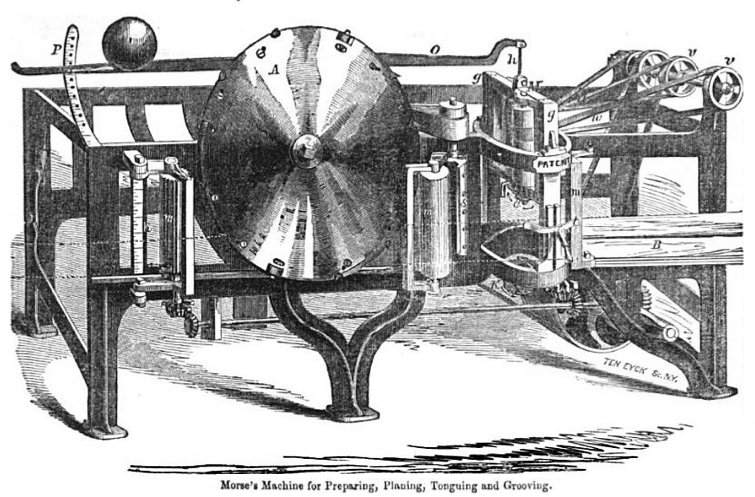

- From the results of the 1855 Fair of the American Institute: "C. B. Morse, Rhinebeck, N. Y., for an improvement in a machine for preparing, tonguing, planing and grooving at one operation. Gold medal." Scientific American was not impressed: "The nomination of jurors, or examining committees, this year, appears to have been very unfortunate. We have seldom seen such displays of stupidity and ignorance as are manifested in some of the awards. Take, for example, the Wood Planing machines; the gold medal was given to an apparatus that, unless we are greatly misinformed, was incapable of working an ordinary sized board. It was an imperfect machine, and generally stuck fast whenever the attempt was made to put it in operation. We have no doubt that it is a good invention, but it utterly failed in its performance at the Palace, and was far from being entitled to a medal. It barely deserved a diploma. On the other hand, there was Barlow's newly patented and truly novel planing machine in full practical operation, at all times during the fair, which was only deemed worthy of a silver medal."

- The 1855-11-10 issue of Scientific American has an article about the Fair of the American Institute:

Morse's Patent Planing Machines—This machine planes both sides of the lumber at once, tongues and grooves at the same time, and if the hoard is wider at one end than the other, reduces it down and brings it out finished, of equal dimensions throughout. The tonguing is done in a peculiar manner, viz., by simultaneously grooving the board on both sides, thus cutting through and leaving a smooth rounded tongue, which is superior to the tongues made by cutting down on the edges of the lumber. This machine appears to have the combined effectiveness of two or more of the ordinary planing machines. It turns out superior work. Price $1000. A very clear description and illustration of its construction was published recently in the SCIENTIFIC AMERICAN. Patented 1855. Now exhibited for the first time hy the inventor. C. B. Morse, Rhinebeck, Duchess Co.,N. Y.

- The 1856-03-08 Scientific American has this classified ad:

Partner Wanted—A practical man, with a small cash capital, to engage in the Sash, Blind, Door, and Planing business, in one of the best locations in the State of New York. The Sash, Blind, and Door business has been carried on successfully for twelve years by the advertise. All the machinery furnished for the business. References exchanged. Address C. B. MORSE Rhinebeck, N.Y.

- Transactions of the American Institute for the year 1856, including that year's Fair of the American Institute: C. B. Morse, Rhinebeck, N. Y., for a rotary planing machine. Bronze medal.

- The 1868-05-02 Scientific American has an article on "Morse's Plan for Centering and Packing Bobbins". See patent 74,402.

- The 1868-08-25 and 1868-09-02 Scientific American had the following classified ad, which may be relevant:

Machine Shop and foundery to let, well established. First-class tools and patterns, now running on cotton, woolen, and general machinery. Work for seventy-five hands. Ill health sold reason for letting. A rare chance. Address H. H. Morse, Attorney-at-law, Rhinebeck, N.Y.

- Listed in Wiley's American Iron Trade Manual of the Leading Iron Industries of the United States, 1874, under "Crucible Steel Works of New York": "Union Steel and Iron Works.—Proprietors, C. B. Morse & J. A. Bennett. Location of works, rhinebeck, New York. Office, 57 Cedar Street. Manufacture under Morse's patent." Under "General Machine Works" is the listing for "Union Steel and Iron Works.—C. B. Morse & J. A. Bennett, Proprietors. Morse's patent tubular steel, cast steel, etc. New York, 4 Dey Street."

- The book Illustrated New York. The Metropolis of To-day, 1888, has an article as follows:

Morse's Novelty Works, Cyrus B. Morse, M. E., Manufacturer of Models, Mechanical Movements, Electrical and Experimental Devices, Wood and Metal Patterns, etc., Dense Cast Metal for all Purposes, Nos. 13, 15, and 17 Franklin Street.—Mr. Cyrus B. Morse, M. E., proprietor of "Morse's Novelty Works," takes rank by general consent among the foremost exponents of mechanical engineering in the metropolis to-day; being a mechanical engineer, inventor, and patent expert of over forty years' practical and successful experience. Among the more notable of his successes in the latter direction may be mentioned the Morse process of densing and fining of metals (a new discovery), which is destined to effect a complete revolution in cast metal, densing and fining the metal and greatly increasing the strength and solidity of cast metals, as shown by tests, cannot fail to command public attention. Years of labor, accompanied with great expense in experimenting to cast metal sound and clean, has resulted in the discovery of a cheap, simple method that changes the porous mass of fluid metal into a soft crystal structure of uniform density. No skill, expense, or change is required for its use. The Morse dense cast-steel hollow ingots for gun forgings, car axles, locomotive tire, gun-barrels, cylinder linings, boiler flues, elevated roads, and other purposes (at greatly reduced cost and of a superior quality), were tested by Paul Dahlgren, C. E. Among American engineers Col. John A. Roebling, Capt. Jas. B. Eads, Gen. Edward W. Serrell, and others have carefully examined and endorsed the Morse process in the production of seamless steel tubing, etc. Writing on the subject Capt. Eads said: " The regularity of the moduli of elasticity is excellent. They will be required for various purposes. The larger the sizes you are able to make, the more valuable they will prove." Gen. Serrell, in writing upon the subject, said: " I am of opinion that if these tubes were regularly in the market there would be, very soon, a large demand for them. They are so strong, so light and stiff, that they must come into use." Col. Roebling frequently expressed his desire to use them in constructing the bridge over the East River between the cities of New York and Brooklyn. This was impracticable at the time, in consequence of the inability of Mr. Morse to furnish it of proper size and in sufficient quantities. The " Morse" process of densing and fining cast metals as fine as hammered steel is now in daily use, any degree of density and fining being obtainable to suit the work the castings are required for; samples, with reference and tests, promptly furnished on application, while all persons interested are invited to examine the new improved method of densing and fining cast metals without extra labor or expense; this practical progress in the art of treating cast metals being heretofore utterly unknown. Dense castings are furnished for all purposes at short notice. Pattern work of all descriptions, for dense castings, done in a skilful manner. It has been demonstrated by daily use that dense cast metal is superior to all other metals for stamping and forming dies, moulds, machinery, railroad, and rapid transit supplies, and all other purposes. Mr. Morse was born in Massachusetts, of Puritan stock, and settled in Rhinebeck, N. Y., in 1840, where he devoted himself to his profession up to 1880, when he moved to the metropolis and three years subsequently established the flourishing enterprise whose name heads this sketch. New inventions are developed and put in working order, the proprietor exercising close personal supervision over every feature and detail of the business. In short, everything comprehended in mechanical engineering and kindred branches are executed in the highest style of the art at reasonable rates. The works are spacious and commodious, with ample and excellent facilities, and are equipped with the latest improved machinery and general appurtenances, while a corps of expert mechanics are employed. This establishment has an exceedingly fine patronage.

|