This firm was created in 1912 when P. P. H. Conover and C. H. Overkamp acquired the Miami Valley Machine Tool Co. Like its predecessor, Conover-Overkamp's product lineup included quick-change gear lathes, grinding machines and a sensitive drill. The company seems to have ceased doing businss in late 1914 or early '15, and the company was formally deregistered in early 1917.

From November 1912 Canadian Machinery

Information Sources

- The State of Ohio lists The Conover-Overkamp Machine & Tool Company's corporate registration date as 1912-02-23. The registration was cancelled on 1917-04-02.

- The May 1912 Proceedings of the Semi-Annual Convention of the National Machine Tool Builders' Association has this snippet.

The Conover-Overkamp Machine & Tool Co. of Dayton, Ohio, has taken over the Miami Valley Machine Co., which company was a member of our Association, and the Conover-Overkamp Machine & Tool Company therefore wishes to be ...

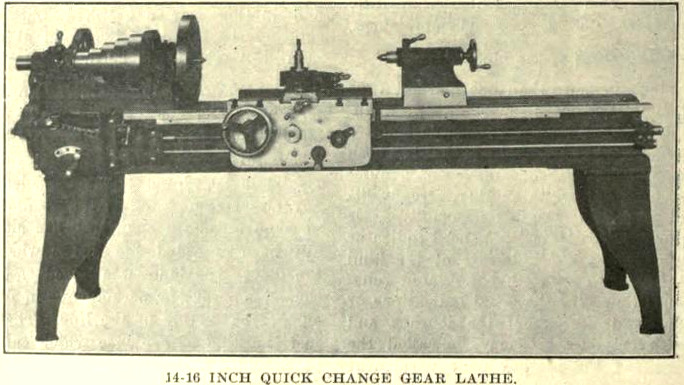

- Article in November 1912 Canadian Machinery on this firm's 14-inch and 16-inch quick-change gear lathes.

- 1913-03-13 The Iron Trade Review.

A motor-driven lathe, built in 14 and 16-inch sizes by the Conover-Overkamp Machine & Tool Co., Dayton, is shown in the accompanying illustration. The headstock is cast in two sections, the lower half forming the headstock proper and the upper half forms the base for the motor and covers all operating parts, thereby eliminating gear guards. The back gears are placed in front of the headstock, making them accessible to the operator without compelling him to walk around the lathe to throw the gears in or out. The drive is obtained from the motor shaft pinion through an intermediate gear to the friction gear on the spindle. This friction gear permits the lathe to be started or stopped while operating and without changing the speed of the motor. The headstock is equipped either with single back gears or double friction back gears and when provided with the latter, the gears are operated by a vertical lever at the front of the headstock.

With a 3 to 1 variable-speed, direct current motor, a wide range of spindle speeds can be obtained. The motor is controlled by a lever on the apron.

- 1913-04-10 The Iron Trade Review, in a larger article about the effects of extensive flooding in parts of Ohio and Pennsylvania.

The Conover-Overkamp Machine & Tool Co., Dayton, by P. P. H. Conover, secretary-treasurer, advises that its machinery, tools, drawing and most of its patterns were saved from the flood. A full is at work cleaning up the shops and operating will be resumed as soon as the power plant is rebuilt. Communications should be addressed as before.

- July 1913 American Machine and Tool Record lists this firm as makers of quick-change gear lathes, toolroom lathes, plain grinding machines, chucking machines, screw-cutting engine lathes, and portable lathes.

- December 1913 Machinery.

Conover-Overkamp High-Speed Lathe

The Conover & Overkamp Machine Tool Co., Dayton, Ohio, recently built the high-speed geared head lathe shown in the accompanying illustrations for use in the Fort Wayne plant of the General Electric Co. It will be seen that the machine is equipped with a single pulley drive and an all-geared head; the machine shown in the illustration is arranged for individual motor drive, although it may be drive from a countershaft with equally good results. There are four geared speed changes. The drive is through a friction clutch located in the headstock, by means of which the lathe may be started, sopped or reversed without paying any attention to the motor.

This machine was designed to operated at 1500 revolutions per minute, which is probably a higher spindle speed than has ever been obtained in an all-geared head lathe. But this is not the limit. During tests to which this lathe was subjected in the Conover & Overkamp shops,the spindle was run at angular speeds up to 3500 revolutions per minute, and at this remarkably high speed, the gears ran without noise. It was also found that the machine could be started, stopped or reversed by means of the friction drive in the head, when running at 3500 revolutions per minute. Lubrication is effected by the splash system, whereby all of the journals in the head and the main spindle bearings are efficiently oiled. Felt wipers are also employed to assist in distributing the oil to the best advantage.

The vertical lever is employed to start, stop or reverse the spindle and the radius plate provides for obtaining of the four speed changes that may be desired. These changes can be made while the machine is running at its maximum speed. There are also four changes of positive geared feed. The apron is of a standard type. This machine is built for handling small chucking work that made by handled at high speed, as well as for regular turning operations. As previously stated, the particular machine shown in the illustration was built for use in the Fort Wayne plant of the General Electric Co., but the Conover & Overkamp Machine Tool Co. is now building these machines as a regular product.

- April 1914 Automobile Trade Directory lists Conover-Overkamp Machine & Tool Co. as a maker of surface grinders, universal grinders, engine lathes, sensitive drilling machines, internal grinders, and reamer and cutter grinders.

- 1915-05-13 The Iron Age.

E. E. Winship. formerly manager of the Cincinnati branch of Manning, Maxwell & Moore, Inc., has been appointed manager of the Cleveland branch, effective May 1. C. H. Overkamp, formerly of the Conover-Overkamp Machine Tool Company, Dayton, Ohio, has been made manager of the Cincinnati office.