|

|

|

|

|

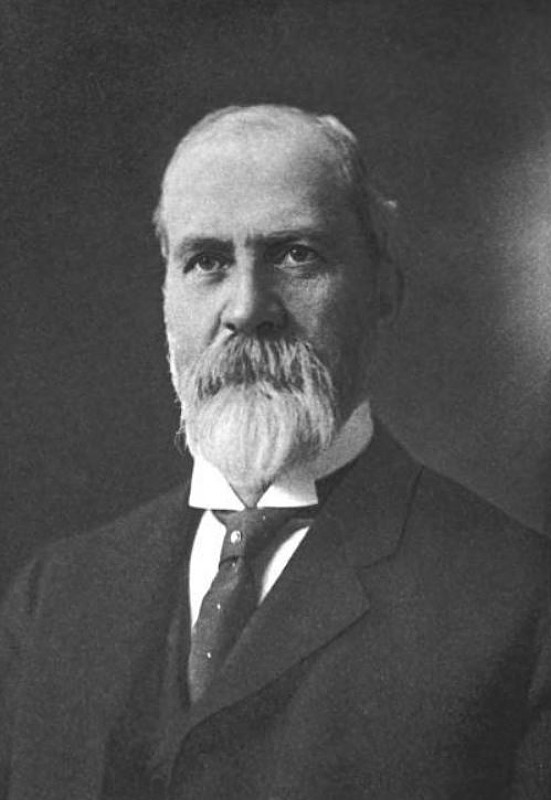

| Henry J. Hendey |

|

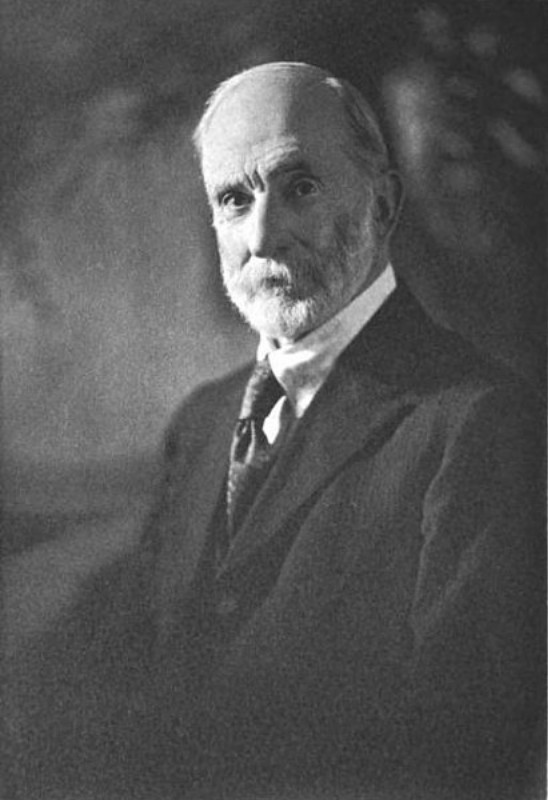

Arthur Hendey |

|

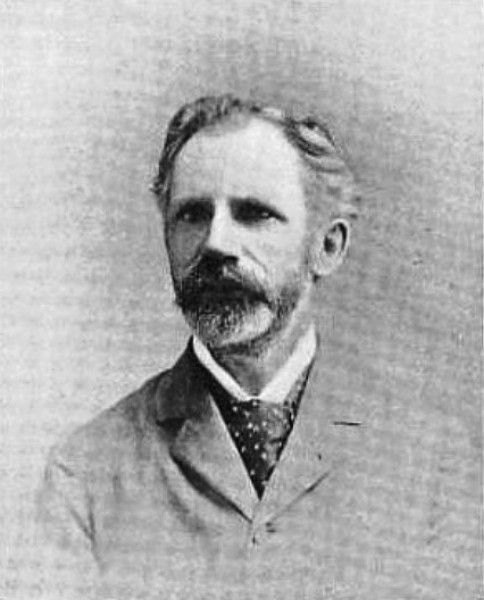

Frederick F. Fuessenich |

Hendey Machine Co. was founded in 1870 as a partnership between Henry J. Hendey and his brother, Arthur Hendey. The firm incorporated in 1874 and Arthur left in 1875. In 1899, Hendey bought the lathe patents of Peter and William Shellenback of the Shellenback Machine Tool Co.

|

|

|

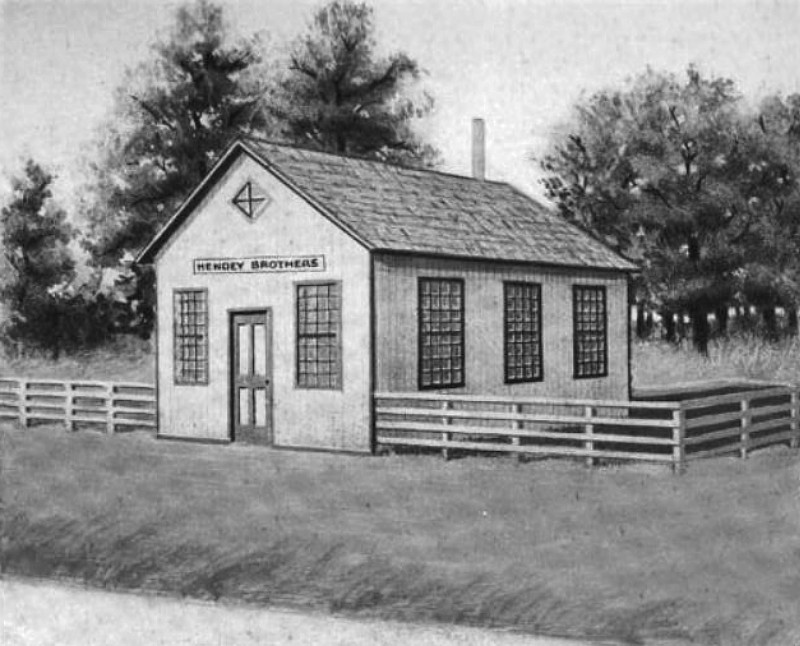

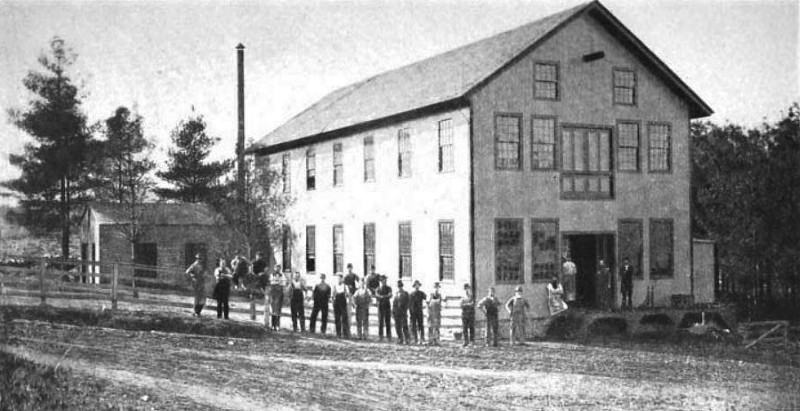

| The Hendey Machine Co's. First Shop in 1871 |

|

The Hendey Machine Co's. Second Shop in 1873 |

|

|

|

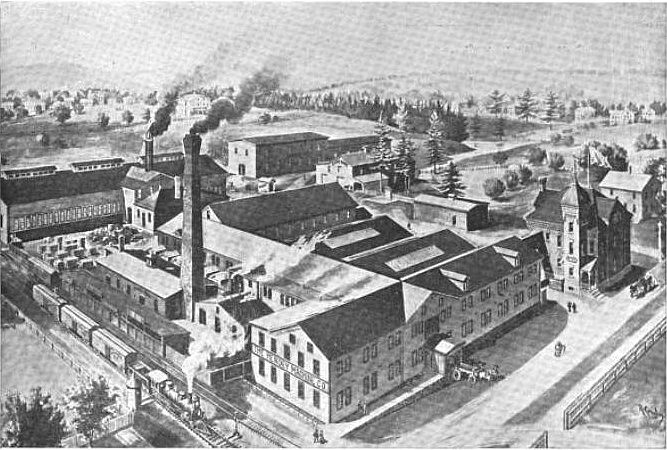

| The Hendey Machine Co. in 1896 |

|

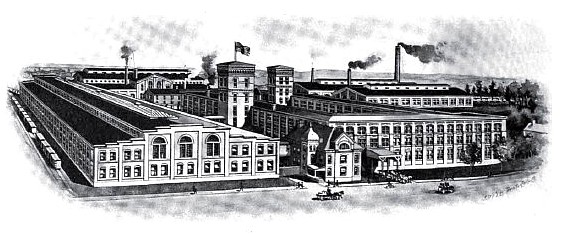

The Hendey Machine Co. in 1907 |

The large business of this Company is the outgrowth of an industry founded by Henry J. and Arthur Hendey, on Litchfield street, in 1870, and which later was moved to what is now the Electric Light Company's building at the East Branch. It was brought to its present location in 1873 and now extends over a large tract bordering on the line of the N. Y., N. H. & H. R. R. and Summer Street. This Company has been exceptionally successful and while other industries of like nature have suffered from the general business depression, it has enjoyed continued and increasing prosperity. Its shops have been run to their fullest capacity, necessitating enlargements to the buildings from time to time, and at present writing new and most modern buildings have just been completed and are now in operation. A private electric plant of large capacity has been installed in the power house. This supplies power for operating the works in the new buildings and it is expected that in the near future the entire plant of the Company will be operated by electricity from the same source. The accompanying illustration shows the premises as they were in 1896, but the completion of the new buildings doubles the establishment in its capacity; it is among the most advanced of modern machine producing plants and in appointments and conveniences it is second to none for the purposes intended. Both steam and electricity are used for power; about 270 men, many of them skilled, are given employment and among these is the Company's corps of expert draughtsmen and patternmakers. A general line of machine tools are made, but the great specialties of the Company, those to which nearly all of the attention is given, are the Hendey Pillar Shaper and the famous Hendey-Norton Lathe. The latter is the invention of Superintendent W. P. Norton and is acknowledged by the trade and by mechanics to be the most practical time and labor saving lathe yet devised, and one of the most useful of recent inventions. The Company was organized in 1874. The original capital of $16,000 has been increased from time to time until it is now $120,000. The Company's officers now are H.J. Hendey, president, and F. F. Fuessenich, secretary and treasurer. The products are sold through agents, largely; they have acquired a world-wide reputation and are known and are in demand wherever machinery manufacturing is conducted, and a large and growing export trade has been established. Messrs. Hendey and Fuessenich, the Company's officers, are among the foremost citizens of the town, and every measure tending to the benefit or development of the place meets with their support. Mr. Hendey was born in England, but was but four years of age when he came with his parents to this country. His boyhood and early manhood were spent in Waterbury, and in that city he learned his vocation. He came to Torrington in 1865 and has since made it his home. He was the first Warden of the Borough of Torrington and for many years has been Warden of Trinity Protestant Episcopal Church. Mr. Fuessenich was Town Auditor for several years and Clerk a couple of years. He is a vestryman at Trinity Church and for a long time has been treasurer ot Seneca Lodge, No. 55, F. & A. M. He was one of the committee of five appointed from Torring1 ton to co-operate with the committee from Winsted in procuring a charter for an electric railway between the two places, has been an earnest worker in bringing the enterprise to a successful issue, and on the organization of the Torrington & Winchester Street Railway Company Mr. Fuessenich was chosen one of Torrington's two representatives on the Board of Directors.

HENDEY MACHINE COMPANY 1870-1920

An anniversary volume entitled "Hendey 1870-1920" has been published by the Hendey Machine Co., Torrington, Conn., in which is recorded the history of the company from the time of its foundation in 1870 until the end of the first half century of its existence. This book contains an interesting account of the founder, Henry J. Hendey, of this well-known machine tool building enterprise, of whom it says that "confronted by adverse conditions, hampered by lack of money, but with a splendid faith in what the future held, his many fine qualities and sheer strength of character asserted themselves. An unshaken courage, a steadfast determination, decision; these were his outstanding characteristics."

THE PARTNERSHIP

Fifty years ago, Henry J. Hendey, a journeyman toolmaker of Wolcottville, Connecticut, with the faith of the fathers and limitations of the hireling, determined to launch and navigate a proprietary machine shop business. To his younger brother Arthur, then a patternmaker in New Haven, he definitely outlined his plan and with such apparent enthusiasm that the younger Hendey immediately acquiesced in the project and the brothers became associated in a humble infant industry, with an unknown product, out of which was built step by step, but with unvarying precept, the present Hendey Works, with a product whose reputation is standard wherever man and metal combine in turning out a finished article.

In the present period of business inactivity, there is a homely lesson in the courage and confidence of the founder of this enterprise, who, due to business depression, was at the time unemployed, but who did not hesitate to face forward, backed only by mentality and muscle and that invariable and constant asset, an unfaltering faith in America.

Different indeed was the modest beginning from the launching of the average industrial plant of today with its finances reasonably underwritten, with its planning engineers and trained specialists. Money was tight and in the early 1870's it took a clear eye and ability tried and trusted to pry it from the bank vaults and persuade the man of means to match his investment against character and ability alone.

At the outset the brothers secured working space in the machine shop of the Turner, Seymour & Judd Company, of Wolcottville, now Torrington, Connecticut, where they continued until the spring of 1871.

Just prior to this move, Henry Hendey, who had returned temporarily to his old twelve-hour per day job, and with that characteristic originality which was later to play such an important part in the destiny of The Hendey Machine Company, completed the 3 H. P. Rotary Engine here pictured and which furnished the motive power for the new plant. The work was done at night after leaving his daily task, which paid him the then top notch machinists' wage of $5 per day.

On a table in the engine room of the present plant, in the shadow of its great successors, this little fellow stands today, silent and inactive; but always a very forceful reminder of cherished hopes, of ambitions realized, a monument in miniature to industrial evolution.

In its inception, naturally enough the tiny shop was not flooded with orders, work came in gradually and Henry Hendey continued working part time in the local manufacturing concerns. Again the brothers' faith in the future, in their ability to meet an increasing demand for a high class product, was evidenced in their next move.

The few dollars they could gather were pooled and Arthur built a small one-story shop on land belonging to their father adjoining the family home. This little structure, the first proprietary works of Hendey Brothers, was later remodeled into a dwelling and is still standing on New Litchfield Street.

About this time a contract, a goodly one in those days, was awarded them, for the construction of twenty wood turning lathes. The details of this premier transaction clearly indicate that even at that time the brothers were thought to be highly capable and thoroughly competent.

With an eye to financing, Henry Hendey continued working part time for others, part for the new plant, and it was deemed expedient to hire one man to assist Arthur. This was an important move and the brothers hesitated somewhat in expanding their labor nearly 50%.

The business continued in this little shop until the spring of 1872, when the amount of work seemed to justify larger quarters than were possible on the homestead and a move was made to the East Branch Spoon Shop. By this time Hendey Brothers were "hiring several men." Business was looking up, good fortune was indeed smiling.

There was at the time a demand for machines for making sewing machine needles, and they were quick to grasp the opportunity and soon became busily engaged in making miller groovers, punches, swaging and various other machines, used in making these needles. Then came shoe nail machines, machinery for lamp burner parts and clocks. Special machinery was then undertaken, such as brass slitters, machines for making wire parts for pianos, for straightening and pointing wire and shaping to numerous forms, foot power jig saws, steam gauge work, glass cutters—in fact, a varied line.

Important indeed, a factor directly affecting the present Hendey product, was the dependable versatility of the brothers as evidenced by the varied line of machines which were then successfully made. It was unquestionably the concentrating later of this competent versatility upon a less diversified line, which laid the very foundation of Hendey Standards. Today the knowledge and understanding of the founder, born of instinct, grafted upon and inbred through generations of workers, is centered upon the production of standardized machines, principally the Lathe, the Shaper, and the Milling Machine. It is superfluous to dwell upon the success of such manufacturing procedure as it is apparent.

It was in the fall of 1872 that Hendey Brothers really concluded the most difficult part of the ascent had been negotiated; ambitions were beginning to be realized; the peak was almost in sight. They decided to build a "new and commodious plant" upon the site of the present works. This was a two-story wooden building 40 x 60 feet with engine and boiler room at one end. When this shop was first occupied in 1873 the brothers had branched out as employers of labor and their pay roll carried from fifteen to twenty men, for, notwithstanding the very decided business depression and panic of that year, they were obtaining all the work they could reliably turn out. They were still working to original form and were exceptionally punctilious in even the smaller details affecting the quality of their product.

THE STOCK COMPANY

Orders were indeed coming their way; but money was scarce and difficult in the collecting. In 1874, therefore, in order to provide necessary financing, a joint stock company was formed with sufficient working capital to enable it to discharge all obligations and carry on the business with reasonable facility. Thus came into existence The Hendey Machine Company.

Shortly after this important mile mark in the Company's history, the shop was visited by an officer; of the Russian Army, who, in his desire to obtain a small lathe, perfect in every operating detail, had called upon all the lathe, makers; in New England, each of whom had declined the commission. Undoubtedly then, as today, such a liberal order was designated as "fussy." The brothers, interested in any machine tool requiring precision, accepted the job.

The lathe, 15" between centers, with a 4" swing, back geared, arranged for screw cutting, in every way a counterpart of the engine lathe of that period, was completed on time and to the perfect satisfaction of the Russian. The most important part of this transaction was not so much in detail as in effect, for without question it was the painstaking execution of this little job which later suggested entering the lathe field and beyond per-adventure the Hendey Standard Engine Lathe of today, with the design and accuracy of a fine timepiece, is the natural and legitimate progeny of this tiny 4" x 15" ancestor.

Soon after the completion of the Russian midget, the brothers built four lathes with 8" swing and 4' beds, which, perhaps through their prompt disposal, the more emphasized the possibilities in this field.

It was truly unfortunate that, owing to ill health, Arthur Hendey, in the spring of 1875, was compelled to withdraw from the Company and move West. The association of the brothers had been both pleasant and productive, as their inclinations and bent were peculiarly coincident. With Arthur's retirement, his interest naturally passed to Henry J. Hendey who, continuing with the Company, made it his life's work, actively directing its affairs until his death in December, 1906.

In 1875 the Hendey Machine Company, under letters patent, commenced the manufacture of friction-drive planers and shapers. In the same year the Company exhibited a friction-drive shaper and iron planer and were awarded a medal of superiority by The American Institute. In 1876, at the Centennial Exposition in Philadelphia, the Company exhibited two shapers and a planer with friction-driving mechanism and were awarded a diploma and another medal of superiority. It is fair to state that awards of this nature were at that time more difficult to obtain and probably more coveted than at present.

Close upon the heels of the panic of '73 there ensued a protracted period of general depression, which historically makes interesting reading; but which in the experience was vastly trying even to those companies and individuals whose resources were reasonably unlimited. With many of the smaller concerns it was a daily struggle for existence, and an early stalwart's advice to the Romans suggesting the potency of spirit and inconstancy of the flesh, was frequently applied with truly gratifying results.

It was about this time that several of the stockholders, discouraged by prevailing conditions, disposed of their holdings and Henry Hendey who had carried an overload since the withdrawal of Arthur, was called upon to assume added responsibility. Resolute and courageous, with his well-founded faith, he promptly surrounded himself with associates qualified to carry on in the other departments of the enterprise.

It is worthy of note in the passing, that from the inception of the business, on throughout his career, Mr. Hendey was blessed with an almost intuitive faith and a fine faculty for attracting to his organization men of ability and vision, men whose aims and ideals were largely in sympathy with his own high standards.

That the Company's sales policy and methods were at times quaintly resourceful and not wholly lacking in humor is borne out by some of the transactions. In one instance a piano was accepted in trade, in another silverware. In both cases this collateral was cautiously unloaded upon stockholders.

In the midst of this depression a very important stroke of business was consummated in a sale of fifty shapers on one order, with payment upon delivery. This deal from a financial viewpoint, proved a timely tonic.

In the marketing of the product there is in the following old guarantee a reflection of the confidence of the production end of the business: “We guarantee perfect satisfaction to anyone who may purchase our machines; and if any reasonable exceptions are taken to the good performance of this machine, it may be returned to us at our expense."

Apparently the purchaser was fully protected.

BUILDING

During the first decade of the Company's existence, between 1870 and 1880, it is an interesting fact, indicated by the old pay roll records, that there was, one year excepted, a mean or average annual gain in the plant's productive labor of 20%. Even in the panic year of '73 this gain was realized. The one year showing a curtailment was 1875. This uniform yearly gain is in itself significant, particularly so when contrasted with an averaging graph of supply and demand for the same period. It is very clearly indicative of sound policy and principles and the high standard of the product, which of a necessity more or less automatically marketed itself, for even on a comparative basis, there was in that period no such clearing house for marketing, as exists today through the medium of modern publicity and sales organizations.

In 1878 Hendey Standard was emphatically recognized by a Naval Board of Engineer Officers appointed to investigate the merits of various types of Shapers, with a view to adopting one make as standard for use throughout the United States Navy. In a two-page closely written report on the Hendey Friction Shaper, the last paragraph is pertinent and convincing: "We fail to discover any disadvantages, and from a conviction that it is the best shaper known to the Board, in the market, and on account of its superiority, we recommend its general use for purposes connected with the U. S. Navy. It also occupies over one-third less space than any other Shaper known for the same range of work."

The Board's findings gave further publicity to Hendey Standard and a certain official stamp, or sanction, which was undoubtedly far-reaching and salutary in effect.

The production of the Company from inception until 1880 covered, as already stated, a varied line of machines, including a few hand Lathes, with a rather indefinite tendency towards a standard line, as indicated by a limited stock of Hand Planers, Friction and Shifting Belt Planers and Friction Shapers.

In the interim between 1873 and 1880 the plant was more than tripled in size, including a detached power plant. In 1884, contrary to prevailing practice, the Company erected its own foundry with a capacity far beyond its current requirements. This innovation was definitely prompted by the desire to supervise and control every process in the production of machine parts, thus making it possible to apply the Hendey Standard to every part of the completed machine.

By 1890 the works were fully seven times larger than the shop of 1873. In 1896 a commodious three-story brick building was added, with the full expectation that the total shop area thus obtained would look well towards future production. Only two years later it became necessary to duplicate the previous brick addition. In 1899 a new foundry was built, double the size and capacity of the original, and a new power house with full electric power equipment.

During the twenty years from 1880 to 1900 the Company's manufacturing policy was to gradually lessen its output of special work, concentrating upon the design and production of a standardized line of machines. Geared Shapers, Drill Presses and Knee Drills were added, also a few Hand and Spinning Lathes, and in 1887 there was a definite drift towards the Lathe when Semi-Automatic, Turning and Heavy Spinning Lathes were added to the line.

In 1890 the Engine Lathe commenced turning out Hendey history and headed the standard line. In addition to the Screw Cutting Lathe, a Turret Head Chucking Lathe and a Plain and Automatic Turret Lathe were included in the regular product.

QUICK CHANGE GEAR LATHE

The year 1892 was epoch-making in the Company's history, the most important since the foundation year, 1870, for in that year the Hendey Machine Company introduced in their Lathes the first commercially successful Quick Change Gear Box equipment and were awarded a gold medal at the Chicago Exposition. The essential advantages of this mechanism in machine tools is too well known to need further reference. From then on Lathes definitely occupied the premier position in the Company's standard line.

The making of Milling Machines was probably originally suggested by the requirements of the Manufacturers of Agricultural Implements, as in the 1894 catalog a Two Spindle Vertical Machine was listed, designed for the milling of Mowing and Reaping Machine Guards. This tool, so far as is known, was the first continuous operating miller made for quantity production.

The last few years of the third decade in the Company's history, saw many improvements in their machines and numerous valuable attachments were designed and produced. In 1900 the Company exhibited their Lathes fitted with the Quick Change Gear Box at the Paris Exposition and received the gold medal.

The latter part of 1900 Hendey Standard received further recognition from the Government in an order from the Rock Island Arsenal, for 240 Lincoln Type Milling Machines. The order, completed the following year, was distinctly interesting and advantageous to the Company in that it was secured in direct competition. It was a new tool for The Hendey Machine Company, moreover, they were compelled to meet certain Arsenal requirements in the specifications. The order was an unqualified testimonial to the Company's reputation for making precision machine tools. Shortly thereafter the Lincoln Milling Machine as well as the Plain and Universal type were regularly manufactured and cataloged.

STANDARDIZING

The year 1900 saw the Company's product practically resolved into a standardized line of Lathes, Shapers and Milling Machines. The three years following the Quick Change Gear Box innovation had truly emphasized the fact that the Engine Lathe was to be the real medium of reflection for Hendey Standards, and the 1900 catalog for the first time listed Lathes and Shapers separately, indicating the importance attached to the former tool.

In marketing Milling Machines it is a significant fact that volume in sales was almost immediate. This was due first, to the Company's reputation for precision, accuracy, simplicity and flexibility of product already established through its other Machine Tools; second, to the Company's ability to offer on this machine, the Quick Change Gear Mechanism which had revolutionized the Engine Lathe field and placed the Hendey Lathe, to be modest, in an extremely enviable position.

The Friction Shaper first produced in 1875 had been a tremendous factor in building the Company's reputation. In 1915 the development of the Crank Shaper with its greater speed, accuracy, and capacity, proved another and most important step forward. This machine embodied many noteworthy changes and improvements, the result of long study and experimentation, and added materially to the Company's reputation for accuracy and flexibility in machine tools.

The period of fourteen years between 1900 and the breaking of the World War, was, with the Hendey Machine Company, one of steady and consistent progress and expansion. From certain trials and vicissitudes of its earlier days, the Company had settled into the easy winning stride acquired through long training and fidelity to high standards—in short, running true to form. It is in no vainglorious spirit that the Founder's ideals are frequently referred to, for they have been and will continue to be the greatest contributing factor in the Company's success and position in the machine tool world.

The increase and latitude in sales, both domestic and foreign, and the type of purchaser the more emphasized the necessity for precision, flexibility and utility in product. The Motor Drive was made more practical, the Tie Bar Headstock, insuring greater rigidity, particularly in heavy duty work, was introduced, the New Combination Gear Box affording thirty-six feed changes without the removal or replacement of a gear, became a reality and the Geared Head Lathe and Geared Drive Milling Machine were added to the line. There was throughout this period constant study with a view to attaining even greater accuracy in the Hendey Precision Lead Screw, the soul of the Engine Lathe. These are a few of the innovations and betterments introduced during this period, not to mention numerous other refinements which were cumulative in their relation to the finished machine.

The growth in size and capacity of plant had been pronounced and, aside from many smaller additions, two large buildings were added; one in 1906, two-storied, for use as a Planer Division for the larger castings, the other in 1910, a four-story machine shop. The increase in plant ground area since inception may be visualized by the plot on the opposite page.

However conscientiously and constantly the Company's efforts are directed towards the perfecting of its product, there is always From 1892 until 1898 the subject of the Metric Lathe was rather indifferently considered by the Company and such machines as were required were individually fitted. With an increasing demand for this equipment, the Company in 1898 produced a purely Metric Lathe in which the Lead and Cross Feed Screws and Nose of Spindle were cut to metric scale and a metric gear box furnished, thus making it possible to produce all metric threads common to those countries using the system.

The general reputation of Hendey Standard abroad, the innovation of metric equipment and the widespread interest created by the Quick Change Gear Box exhibited at the Chicago Exposition in 1892 brought orders from the government arsenals of Europe. The accuracy and flexibility of the machine, coupled with its power and rigidity, attracted the better class of manufacturers and the sales increased until today, it is hardly an exaggeration to say there are few of the higher type of European works whose equipment does not include Hendey Lathes.

The export of the Company's product to the Orient has been heavy. In one in stance, two Hendey Lathes were shipped to Calcutta knocked down, transported inland to the terminus of the rail line and carried 400 miles to destination by Coolies.

South Africa imports Hendey Lathes and they are in use in the copper mines of Spain and South America. The Company's records show South American shipments knocked down, which in reaching their destination crossed the Andees by mule power.

The Company's export business during the World War in itself constitutes a story interesting and significant, not alone in point of volume, but rather in the actual performance of its tools under most exacting and in many cases abnormal requirements and demands for accuracy combined with production.

PATENTS AND THEIR PROGENY

For some thirty years past the policy of the Company has been one of standardizing, the adoption of a basic line composed chiefly of the Lathe, the Shaper, and the Milling Machine. Throughout this period all possible concentration and study has been brought to bear upon original improvements, refinements, and betterments. Radical departure from the main line of accuracy, utility, and flexibility have been discouraged and the Company's efforts have been largely focused upon the development of the principles and improvements embodied in Letters Patent issued to Eli J. Manville, Wendell P. Norton, Constant Bouillon, and George H. Knight.

A patent, essentially a crystallized idea, is susceptible of development and progressive improvement. The Company's policy in this respect has been to market no betterment without a protracted period of practical experimentation, to the end that each refinement may in itself reflect Hendey Standard.

Information Sources

- More history and machine information can be found at Tony Griffith's Lathe web site.

- The Torrington Register Souvenir Edition, by the Register Printing Co. 1897 page 46

- American Lathe Builders: 1810-1910, by Kenneth L. Cope, 2001 page 77

- Machinery Magazine, V28, May 1922, pg. 741

- >The Hendey Machine Company, 1870-1920, published in 1922

- Machine serial numbers from 1920 to 1953 may found here