Manufacturers Index - Cleveland Automatic Machine Co.

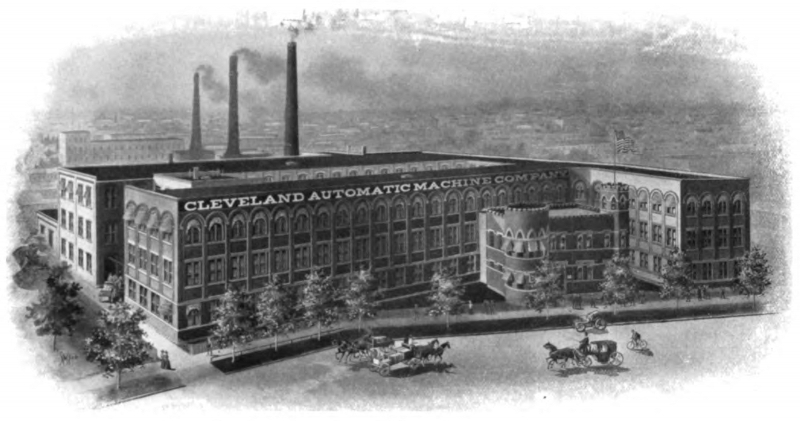

Cleveland Automatic Machine Co.

Cleveland, OH, U.S.A.

Manufacturer Class:

Metal Working Machinery

1907

In 1866 Thomas Howard White, who had already been manufacturing sewing machines in Massachusetts, relocated to Cleveland, Ohio, and established the White Manufacturing Co. to manufacture sewing machines. Over the ensuing decades White expanded his product line in a variety of directions—bicycles, automobiles, phonographs, roller skates, etc. The business grew to a substantial concern of 1,000 employees.

White aggressively pursued improvements to both his products and their manufacturing processes, and along the way his mechanics and engineers created improvements to multi-spindle drill presses, automatic lathes, and screw-making machines. In 1892 he established a new company to build and sell his improved screw machine, the Cleveland Machine Screw Co., incorporated in Ohio. In late 1893 that firm acquired Fitchburg, Mass., ball-bearing machinery manufacturer Grant Anti-Friction Ball Co., which owned some key patents for manufacturing bearing balls. The facilities of the Grant company were relocated to Cleveland.

In 1898 the Cleveland Machine Screw Co. was re-incorporated under the laws of West Virginia. The company name led to confusion as to what the company made, and in 1902 the name was changed to the Cleveland Automatic Machine Co., which was incorporated under the laws of New Jersey. It was perhaps at this time that T. H. White relinquished presidency of the company to A. L. Garford. In 1916 the company reorganized yet again, this time under the laws of Ohio.

Under either name the company was quietly successful. In the early 1940s the R. K. LeBlond Machine Tool Co. acquired a controlling interest in the Cleveland Automatic Machine Co. but continued to operate the business under its original name. In 1946 another LeBlond subsidiary, LeBlond Engineering, was merged into the Cleveland Automatic Machine Co. organization. At the end of 1956, LeBlond acquired pigment-machinery manufacturer J. H. Day Co., Inc. and merged it into the Cleveland Automatic Machine Co., where it operated as the J. H. Day Company Division.

Information Sources

- 1893 Public Documents of Massachusetts lists, among the events for Fitchburg, November 1893, "Grant Anti-Friction Ball Co. sold business to Cleveland Machine Screw Co.; business to be removed to Cleveland, Ohio."

- November 1902 Modern Machinery. "The Cleveland Machine Screw Co.. Cleveland, O., has changed its name to the Cleveland Automatic Machine Co. and issued a new catalogue. The company has enlarged and extended excellent facilities for making automatic machine work of high grade.". Later on the same page, "The Cleveland Automatic Machine Company, formerly the Cleveland Machine Screw Company, which was incorporated in New Jersey, was recently qualified to do business in Ohio. A. L. Garford, of Elyria, O., president of the Automobile and Cycle Parts Company, is president of the new company, which was incorporated for $1,000,000. The works are at Central and Second avenues, Cleveland, O."

- For sale online: 1902 bond certificate, Cleveland Automatic Machine Co. First Mortgage 5% coupon Gold Bond of $80.

- 1902 Annual Report of the Secretary of State to the Governor of the State of Ohio lists Cleveland Automatic Machine Company, registered in New Jersey, as a foreign corporation with capital stock of $1,000,000.

- 1905 Documents of the ... Legislature of the State of New Jersey lists Cleveland Automatic Machine Company as having $1,000,000 capital stock and having been assessed $1,000 tax upon capital stock.

- 1907 Moody's Manual of Railroads and Corporation Securities.

Cleveland Automatic Machine Co.—Inc. Oct. 1902, in N. J., as successor to the Cleveland Machine Screw Co., a West Virginia corporation organized in 1898 to acquired the properties and business of a company incorporated under Ohio laws in Dec, 1892. The plant, together with real estate, located at Cleveland, Ohio, is understood to have cost $1,000,000.

Capital Stock.—Authorized, $1,500,000; outstanding, $1,000,000; par, $100.

Bonded Debt.Authorized and issued, $500,000 5s, of which about $100,000 have been retired by sinking fund.

Officers: A. L. Garford, Pres.; J. P. Brophy, V.P.; Geo. F. Kelly, Sec.; Geo F Clemo, Treas.

Office, Cleveland, Ohio.

- February 1916 Machinery, in the Obituaries.

Robert H. Grant, a well-known expert in the manufacture of balls and design of ball-making machinery, died at his home in Ann Arbor, Mich., January 11. He was a graduate of the Fitchbnrg High School, Fitchburg, Mass, and the Fairchild Institute of Flushing, N. Y. His mechanical training was obtained with the Pratt & Whitney Co. of Hartford and the Simonds Rolling Machine Co., Fitchburg, where his father, John J. Grant, who built and equipped the first ball-bearing factory, was superintendent. With his father, Mr. Grant organized the Grant Anti-Friction Ball Co., which was later consolidated with the Cleveland Machine Screw Co. of Cleveland, Ohio. When the Cleveland Machine Screw Co. was sold to a French syndicate, Mr. Grant organized the Grant Ball Co. of Cleveland, which manufactured balls and screw machine products. Selling his interest in this company, Mr. Grant became superintendent of the Standard Roller Bearing Co. of Philadelphia, Pa., which at that time had only a small factory, employing fifteen men. Within three years the company acquired control of ninety per cent of the ball trade of thi country and had built and equipped a plant covering several acres. After having been with the company eight years, Mr. Grant resigned and spent some years designing machinery and equipping plants for the manufacture of balls and ball and roller bearings. Mr. Grant was a valued contributor to Machinery. In the February, 1912, number he began a series of articles on the manufacture of steel balls and ball and roller bearings, which made public for the first time much valuable information on the theory and practice of ball making.

- 1916 Poor's Manual of Industrials.

Cleveland Automatic Machine Co. (Ohio).—Organized March 1916, and acquired all of the property and assets of the Cleveland Automatic Machine Co., of N. J., as a going business in Jan. 1016 (see Manual of Industrials for 1915). The New Jersey company was dissolved by its stockholders. Plant at Cleveland, O.

Capital Stock.—Common, $2,500,000 (shares, $50; 7 p. c. cumulative preferred, $1,500,000 (shares, $100,)—, $4,000,000...

Directors.—A. L. Garford, Elyria, O.; J. P. Brophy, C. E. Farnsworth, H. H. Johnson, Cleveland, O.; Harvey D. Gibson, New York, N.Y.; J. K. Secor, Walter F. Brown, Toledo, O.

Officers.—A. L. Garford, Pres., Elyria, O.: J. P. Brophy, Vice-Pres., David L. Johnson, Sec.; H. M. Rich, Treas., Cleveland, O. Office, Cleveland, O.

- 1931 book, National Cyclopaedia of American Biography.

White, Thomas Howard, manufacturer, was born at Phillipston, Mass., Apr. 26, 1836, son of Windsor and Elizabeth (Pierce) White and a descendant of Thomas White... Being mechanically skillful and naturally ambitious, he devoted every moment he could find to experimenting with strange machines. It was the age of inventions and one of the most fascinating devices that had been brought out was a machine for sewing. [William L. Grout, a friend of Thomas H. White,] experimented patiently with this promising device and in 1857 invented a small hand-power sewing machine of his own, on which [they] obtained patents in 1859. [They] began to manufacture [the] machine in 1858 in a factory at Templeton, with a capital of $350 and with William L. Grout, who acted as salesman, as a partner. "The New England" was the name of this machine, the retail price of which was ten dollars, and although the partnership with Grout lasted only a year, the business prospered and in 1863 the demand had grown to such an extent that White moved to a larger factory at Orange, Mass., where he manufactured for three years. Seeking larger fields and greater manufacturing facilities, he removed to Cleveland, O., in 1866, taking with him a few of his best mechanics, and there founded the White Manufacturing Co. For ten years the new factory built sewing machine heads for W. G. Wilson, until that company purchased the existing patterns, templets and special equipment, and established in independent plant in Chicago, Ill. A new model had been perfected in the meantime by George Wells Baker and D'Arcy Porter of the White organization and its manufacture was commenced at once, the company having been reorganized under the name of the White Sewing Machine Company. The business grew from an original production of twenty-five machines a month to no fewer than 2,000 a week in 1882; an extensive organization of branch dealers was established in the United States and following the opening of a London office in 1880, the company's foreign trade grew rapidly. At the time of the death of its founder in 1914, the company's capitalization had grown to $1,225,000, its main plan at Cleveland occupied more than 275,000 [square] feet of floor space and it employed close to 1,000 persons. Production had grown enormously and the White sewing machine was sold in every civilized country. From the first Mr. White devoted most of his time to problems of finance and production, engaging others of greater inventive genius and mechanical skill to improve the machine itself. In order to reduce production costs he engaged the best mechanical engineering talent to devise manufacturing economies, and in his factory the full automatic lathe, the multiple spindle drill and the screw machine were brought to a high degree of perfection. The success of his methods is indicated by the fact that under his leadership the White Sewing Machine Co. (now a subsidiary of the White Sewing Machine Corporation) developed into the second largest manufacturer of sewing machines in the world. From time to time he enlarged the range of the business by adding new products, such as roller skates, bicycles, phonographs and automobiles. During 1894-98 the company produced White bicycles at the rate of 10,000 a year, and in the same period it produced 450,000 bicycle pedals for other bicycle manufacturers. In 1900 the company entered the automobile manufacturing field and this department of the business, which was developed largely by the sons of the founder under the stimulus of his encouragement and guidance, grew so rapidly that it was established as a separate organization, the White Company, in 1906. Thomas H. White was also the organizer and president of the Cleveland Machine Screw Company (later the Cleveland Automatic Machine Company), which manufactured screw-making machinery. He continued as president of the White Sewing Machine Company until his death.

- 1946 IW: The Management Magazine.

Cleveland Automatic and LeBlond Engineering Merge—Stockholders of the Cleveland Automatic Machine Co., Cleveland, have authorized a merger of the LeBlond Engineering Co., Cincinnati, into their company. The business of both will be continued under the name of Cleveland Automatic Machine Co. The Cincinnati plant will operate as a division of Cleveland Automatic.

LeBlond Engineering was organized in 1940 and was wholly owned by R. K. LeBlond Machine Tool Co. The merger into Cleveland Automatic gives LeBlond interest 84 per cent stock ownership in Cleveland Automatic.

- May/June 1967 LeBlond News, via a practicalmachinist.com discussion.

Just prior to World War II, the company (RK LeBlond Machine Tool) established LeBlond Engineering and purchased the Beech St. Norwood Plant. LeBlond Engineering produced Rapid Production lathes, hoisting units for lift trucks, 11", 13" and 15" Regal lathes and gun boring lathes.

In the early '40s the company purchased Cleveland Automatic Machine Co. which was moved to the LeBlond Engineering complex. Cleveland Automatic produced automatic screw machines and die casting machines.

- 1957 issue of Paint Industry Magazine, American Paint Journal, and Paint and Varnish Production. "J. H. Day Co. Announce Merger / J. H. Day Co. to Become Division...Cincinnati, Jan. 21.—Harold R. LeBlond, president of The Cleveland Automatic Machine Company, this city, has announced its merger with the J. H. Day Company, Inc., also of Cincinnati. The merger became effective on December 31, 1956, and the Day operations will be continued as the J. H. Day Company Division of The Cleveland Automatic Machine Company. The merger of the two companies is part of the expansion and diversification program of The R. K. LeBlond Machine Tool Company which owns The Cleveland Automatic Machine Company. The 75 year old R. K. LeBlond Machine Tool which is the world's largest builder of a complete line of lathes, recently acquired The Fosdick Machine Tool Company of Cincinnati, builders of drilling machines, grinders and boring mills. The Cleveland Automatic Machine Company was founded in..."

- 1959 book, History of the Grinding Machine: A Historical Study in Tools and Precision Production, by Robert S. Woodbury. "...meet the standards necessary for ball bearings. It was not until the work of Henry Richardson in 1887 that it was possible to produce precision hardened balls. Richardson's ball bearing grinder used essentially the principle of Barker and Holt's, but his machine incorporated the features necessary to produce precision work. From his invention, the ball..."

- 1960 edition of The US Armed Forces Supply Support Center's Metalworking Machinery lists Cleveland Automatic Machine Co., The / 4932 Beech Street / Cincinnati 12, Ohio / NOTE: Formerly known as Cleveland Automatic Machine Co., Cleveland, Ohio". Products listed under them are

- * Lathe, Chucking 4 Spindle, Horizontal, Automatic, Model M, 4" swing.

- * Lathe, Chucking 4 Spindle, Horizontal, Automatic, Model M, 6½" swing.

- * Lathe, Chucking 4 Spindle, Horizontal, Automatic, Model M, 5½" swing.

- * Lathe, Chucking 4 Spindle, Horizontal, Automatic, Model K, 6½" swing.

- * Lathe, Chucking 4 Spindle, Horizontal, Automatic, Model M, 8" swing.

- * Lathe, Chucking 4 Spindle, Horizontal, Automatic, Model M, 8" swing.

- * Lathe, Chucking 4 Spindle, Horizontal, Automatic, Model K, 9" swing.

- * Lathe, Chucking 5 Spindle, Horizontal, Automatic, Model K, 4 3/4" swing.

- * Screw Machine, Automatic, Bar, Horizontal, Single Spindle, Model B, 9/16" dia. bar cap.

- * Screw Machine, Automatic, Bar, Horizontal, Single Spindle, Model A, 1 1/16" dia. bar cap.

- * Screw Machine, Automatic, Bar, Horizontal, Single Spindle, Model B, 1 1/16" dia. bar cap.

- * Screw Machine, Automatic, Bar, Horizontal, Single Spindle, Model AA, 1 1/16" dia. bar cap.

- * Screw Machine, Automatic, Bar, Horizontal, Single Spindle, Model C, 1 1/4" dia. bar cap.

- * Screw Machine, Automatic, Bar, Horizontal, Single Spindle, Model AB, 1 3/8" dia. bar cap.

American Milling Machine Builders: 1820-1920 by Kenneth L. Cope, 2007, page 71

National Museum of American History has a collection of 14 catalogs and manuals from Cleveland Automatic Machine Co. Contents include "Morton vacuum systems, high pressure hydraulic die casting machines, milling machines and attachments, drills, forms, reams, and cut-offs ready for grinding, taps, machining tools, single pulley belt or motor driven double end threading ..."

|