Manufacturers Index - McBeth, Bentel, & Margedant

McBeth, Bentel, & Margedant

Hamilton, OH, U.S.A.

Manufacturer Class:

Wood Working Machinery

Last Modified: Dec 15 2010 8:55PM by Jeff_Joslin

If you have information to add to this entry, please

contact the Site Historian.

|

Sometime shortly before the Civil War, the firm of Lee & Leavitt ceased operations, and most of the operations were acquired by Charles E. McBeth, who resumed the manufacture of woodworking machinery and agricultural products. D. W. McClung joined him in 1867 and the business became McBeth & McClung.

At this point they made a very smart move, buying a half interest in a new patent for a "universal wood-worker" that had been granted to Henry Climer and John D. Riley. This machine proved to be the genesis of the modern jointer.

D. W. McClung sold out to Jacob Shaffer in 1868, and the name became McBeth, Shaffer & Co. Shaffer sold out to William C. Margedant in 1870. At the time of the Ohio State Fair in 1870, the name was unchanged.

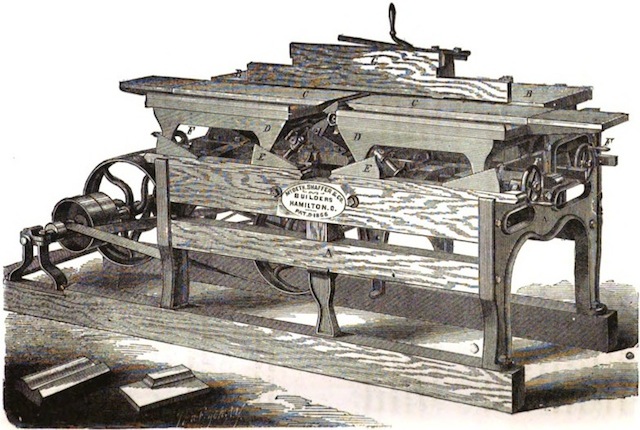

Front view of the McBeth, Shaffer & Co. "Universal Wood Working Machine" from the Twenty-Fifth Annual Report of the Ohio State Board of Agriculture, 1870.

Later in 1870 the name changed to McBeth, Bentel & Margedant when Frederick Bentel joined the firm. In May 1873 a fire seriously damaged their shop, which created a financial strain that led to McBeth leaving the firm. He was replaced by a former employer of Margedant's, John Sohn. The name changed to Bentel, Margedant & Co., the change occurring late in 1874.

Information Sources

- Twenty-Fifth Annual Report of the Ohio State Board of Agriculture, 1870. pp. 213ff:

Messrs. McBeth, Shafer & Co., Hamilton, Ohio, presented a very superior wood-worker as a universal wood-working machine—planing, sawing, 'routing,' tenoning, boring, and working mouldings—indeed, almost a universal shop-worker, and must be regarded as especially desirable in a shop for general work. (description of The Improved Universal Wood-Worker, deleted). ... McBeth, Shaffer & Co. also exhibit a wood boring machine of fine construction, capable of boring eleven inches deep, with cone pulleys, arranged for three speeds, to suit different sized bits. It is provided with an adjustable table, so that it can be worked at any angle. It is worked by traversing mandrel, cast steel countershaft, and pulleys on swivel self-adjusting boxes, and has been pronounced by the best judges who witnessed its operation as a strong, simple and easily managed machine. ... McBeth, Shaffer & Co., Hamilton, best moulding machine, $10; best mortising machine, $10; best sash machine, $10; best tenoning machine, $10. The Report of the Committee includes the following paragraphs:

The foregoing engravings illustrate an improved wood working machine which is now in successful operation in over one hundred and sixty (160) of the best shops in the country, representing almost, if not quite, every variety of wood working, sashes, doors and blinds, furniture and bedsteads; in railroad car shops, wagon and carriage shops, manufactories of distillers' and brewers' tubs, machine shops, brush factories, etc., etc. Its uses are rabbeting, plowing, gaining, beveling, jointing, hand-matching, planing out of wind, etc. It has capacity for heavy or light work, gaming from 3-16 inch wide to 4 inch wide, and ? 1/2 inch deep at one cut in hard wood, also half round or bevel gains for boxing, and is especially adapted for planing turned work, such as bedstead posts, stand and table legs, and routing for the post and rail irons, making glue joints, rolling joints for table leaves, also shallow mortices for joint bolts, planing out of wind, smoothing, jointing, and rabbeting blinds at one operation. It is not complicated, and is quickly adjusted, requiring no more time than to remove one head and put on another. It may be converted into a saw table by the same operation, and then adjusted by turning the hand wheels.

In Fig. 2, showing sticker side or molder attachment with side head, the fence, which is used for squaring, beveling, jointing, rabbeting, etc., is removed, giving a view of the tops of the three beds, which are made of iron and planed straight, the front ones having a recess for slide boards, used in sawing, gaining, etc. The feed rollers never rise out of gear and are always straight with the bed (or parallel), thus holding the work firmly on both sides while being passed through. It will stick sash or an eight-inch crown molding, and has a fifteen-inch drop. Two persons can work on it at the same time advantageously. Three kinds are made, one with the boring and routing attachment, one with sticker or molder attachment for planing one side (without side-head), and one for planing two sides. The principal parts are lettered for reference in Fig. 1, and the following description will give the reader a general idea of the construction and capacity of the machine:

A is the main frame. ? is an adjustable table extending the full length of the machine. ? and ? are also adjustable tables, independent of each other and of table B, sliding upon beds D, which rest upon the inclines E. These inclines are bolted to a sliding frame, and all the tables are raised and lowered by forcing the inclines backward and forward by means of screws F.

G is an iron frame, graduated in half and quarter inches, fastened to and forming an exact right angle with the table B, and held by wing nuts through slots in the arms, and which can be moved over the tops of the knives.

For dressing straight work the bed C, in rear of tho bits, is adjusted to the exact hight of the circle described by the bits in revolving. The bed C, in front of the bits, must be adjusted as much lower than the rear bed as the thickness of the cut required. Thus, as soon as the work has passed to tho rear bed, it has a solid bearing on both sides of the bit, and will be dressed entirely straight and out of wind. In squaring the fence is used so as to have an exact right angle. For rabbeting, gaining or fluting, both beds are lowered to the desired depths below the knives. For tapering one end of tho work is rested on the rear bed before cutting, and the front bed is depressed to tho depth of the taper required. The work is then passed over as usual. When access to the bit is desired, either for the purpose of sharpening them or changing the head, a wing nut underneath the table ? (not shown) is loosened, which permits tho tables to slide backward and forward, and to be adjusted for a saw or head of any size required. There is also an arrangement shown attached to beds D and A, and to cross-ties below, whereby the tables are made to move, in lowering and raising, in an oblique direction, and are carried towards the bits in raising, and away from them when lowering, thereby preventing the bits from striking the beds, when adjusted, while running. The bevel nut and fence are made in a single piece, and can be adjusted an any angle. A sticker attachment is also made, with feed rollers, etc., for planing one and two sides in place of the boring and routing attachment. It will plane eight inches wide and has a fouiteen-inch drop.

This machine was carefully and admirably examined by throngs of visitors to the Cincinnati Exposition, many of whom were practical mechanics.

Those who had never before seen it were astonished to find that a machine performing so many kinds of work should be so remarkable for simplicity of construction and movement. They saw specimens of each of the numerous kinds of work it performs, done in the most superior manner and with a rapidity that seemed impossible to many observant mechanics. Numerous manufacturers, who found here a favorable opportunity for a perfect demonstration of its merits, testified their appreciation by ordering them for their own establishments.

Detailed information and description may be had by addressing the manufacturers, Messrs. McBeth, Shaffer & Co., Hamilton, Ohio.

- Mentioned in an article in an 1872 issue of Manufacturer & Builder.

- An 1871 patent was issued to Charles E. McBeth, Frederick Bentel, William C. Margedant, and Henry Climer, for improvements to Climer and Riley's jointer patent.

- For more sources, see the entry for Bentel, Margedant & Co.

|