In 1895, J. P. Williams & Co. got a contract to make fans, including the motors, during spring and summer; the rest of the year they made electric motors for other uses. Their fan lineup consisted of the "Globe" model, and then its successor, the "Paragon". In 1898 the George C. Towle Manufacturing Co. was incorporated to manufacture the Paragon fans and motors. The name Paragon Fan & Motor Co. was somehow in the mix as well but its relationship to the Towle company is not understood. In any event, in 1899 the Paragon Fan & Motor Co. was purchased by General Incandescent Arc Light Co., and relocated to New York; the Towle company remained in Lancaster. In late 1903 the George C. Towle Manufacturing Co. was renamed to the Fidelity Electric Co. The company survived until 1991, when it was acquired by Marathon Inc.

|

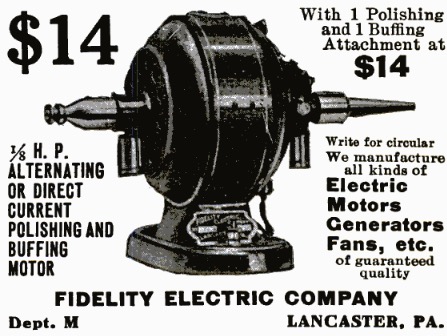

| From March 1909 Popular Mechanics |

Much of the motors made by Fidelity Electric were for specialized applications such as fans, sewing machines, and dental appliances, but they did make general-purpose motors ranging from small fractional horsepower size up to 30 HP.

Information Sources

- 1895: From The Electrical Engineer Volume 19 No. 370 (or 378 or 379), p. 602, J. P. Williams & Co. was building motors and "Globe" fans. The business was headquartered at 123 Liberty St., New York.

- 1896: May 1896 The Electrical Age mentions that J. P. Williams was at 39-41 Cortlandt St.

- 1897: The 1897-08-25 issue of Electrical Review had the following news item.

The "Paragon" Fan Motor

In view of the very large output of "Paragon" fans for the season of 1897, great credit is due Mr. J. P. Williams, the inventor, who as devoted more than three years of energy in evolving the present for of "Paragon" motor, which is, as may be generally known, the outcome of the "Globe" motor. The principal of the motor is a radical departure in this line of construction. At the present time the factory at Lancaster, Pa., where these motors are made, is employing 280 men, and even with that large complement of workmen the company is having great difficulty in producing fans fast enough for the season's demand. It is the intention of the manufacturers to operate during the entire winter months for the following season; in fact, the sales have been so much greater than even the makers anticipated that the factory equipment of machinery and facilities has been doubled for the past three months, with the result, as Mr. Williams remarked, that "we shall see over 6,000 'Paragon' fans this season." We present herewith two views in the company's factory at Lancaster.

- In the 1898-05-05 issue of The Electrical Engineer:

George C. Towle Manufacturing Co. Chartered.

A charter has been issued to the George C. Towle Manufacturing Company to manufacture electrical machinery at Lancaster, Pa. The directors are G. C. Towle, J. E. Hubley and R. Blickenderfer, Lancaster, Pa.; G. A. Towle, Lowell, Mass., and J. P. Williams, of New York. The new company has the contract for making the Paragon fan and power motors for the season of 1898.

- 1899: Paragon Fan & Motor Co. purchased by General Incandescent Arc Light Co. and moved to NY. George C. Towle Co. continued to make fan motors in Lancaster.

- 1903: CEO John Fourney Stauffer of George C. Towle Co. dies.

- 1903 (late fall): George C. Towle Co. renamed to Fidelity Electric Co., with Charles Stauffer (son of John) in charge.

- Physical and Industrial Geography of Lancaster County, Pennsylvania, by Jenry Justin Roddy, 1916, gives a history of Paragon and Fidelity. It is not consistent with the primary sources listed above.

Electrical Machinery.—In 1895, a small company known as the Paragon Fan and Motor Company began making electrical supplies and jeweler's tools on East Chestnut street. Its business responding to modern demands grew rapidly and necessitated expansion in housing, equipment and number of workmen. Hence in 1898, The Fidelity Electric Company was incorporated and located on North Arch street. Here, under a number of patents it now manufactures a full line of electric motors for both alternating and direct current. They vary in size from the smallest type weighing 1½; pounds up to those of 30 horse power. Its motors are adapted to running sewing machines, dentists' and jewelers' appliances, printing presses and other forms of machinery. Electric Fans, and apparatus for X-ray and other medical uses are also built.

The company has a wide reputation and employs now about 100 men. At no time in the eighteen years of its existence has the plant been closed for more than three working days.

When started, only two men in Lancaster could wind electrical apparatus. Now, by running a series of apprentices, including machinists and electricians, preferably from Lancaster county, many young men are receiving valuable training for highly technical and skilled employments.

- The 2014 Marathon catalog has a company timeline that includes, for 1991, "Fidelity Electric is purchased, significantly expanding Marathon’s product offering of 5-20kW Pancake generators".