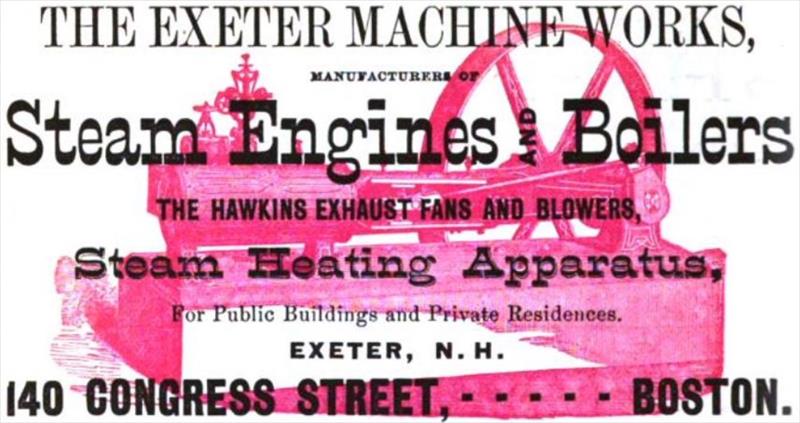

“In 1860 an incorporated company erected buildings, consisting of a machine shop. 160x35 feet, two-stories high; an iron foundry, 106x75 feet; blacksmiths’ shop, brass foundry, and other necessary buildings to carry on the manufacture of steam engines, machinery and brass and iron fittings. The shops were all provided with new tools of the most improved kind for the several branches of manufacture, and when in successful operation gave employment to 150 hands. But meeting with severe losses, they were obliged to sell out at a great sacrifice, when the machinery department was again started by William Burlingame, under its present name of Exeter Machine Works.

The works are driven by a 20 horse-power variable cut-off engine, supplied of their own manufacture; the buildings of various sizes of both being one of the specialties of the concern.

These boilers, from their mode of construction and the great amount of pressure, which they are able to stand, renders them safe from explosions in every sense of the word, as well as in economy of fuel and durability Another branch of their manufacture is small engines and drilling lathes of every size for jeweler and model makers, and a great variety of wood working machinery.

The works are very conveniently located on the Boston and Maine railroad, so that freight cars can be loaded direct from the works into the cars.” (Quote from 1869)

|

| From Sampson, Davenport & Co.'s Boston Directory |

Information Sources

- Webb's New England Statistical Gazetteer,1869, pg. 89

- American Steam Engine Builders: 1800-1900 by Kenneth L. Cope, 2006 page 85

- Carriage and Wagon Makers Machinery and Tools by Kenneth L. Cope, 2004 page 88