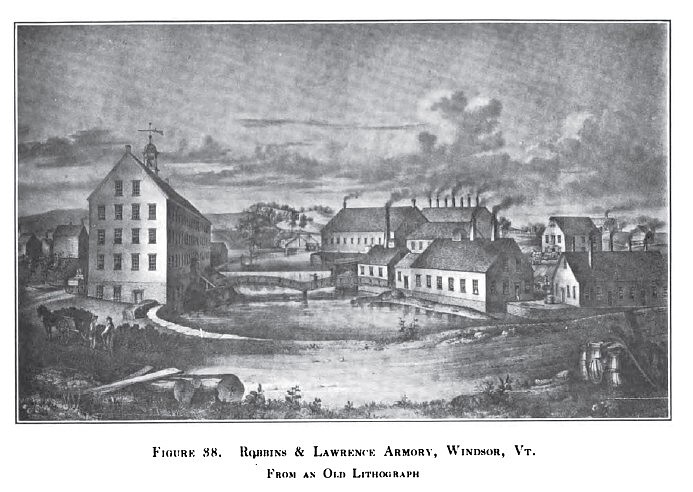

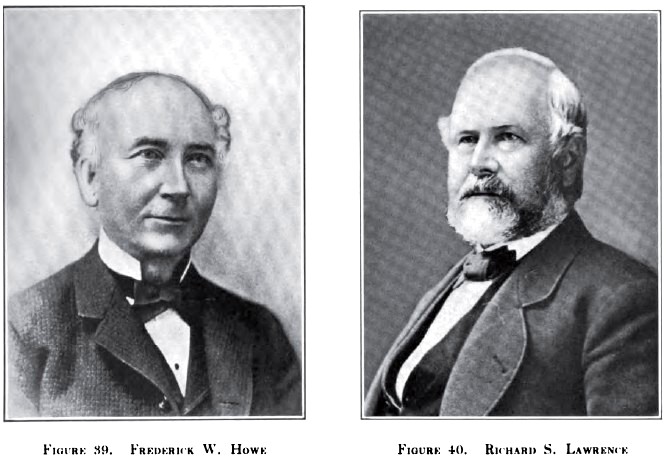

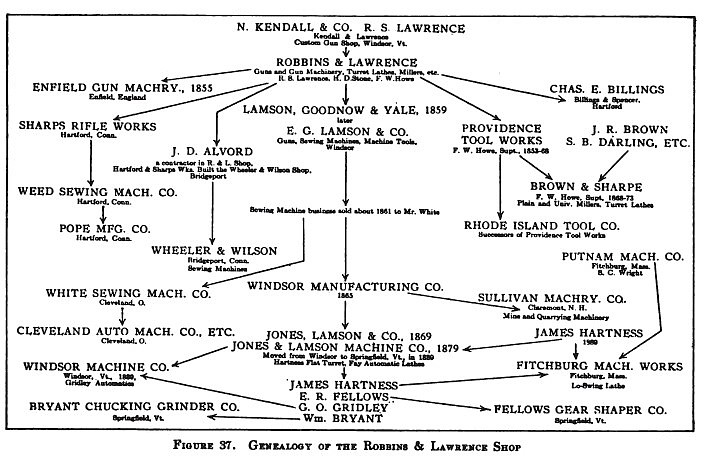

The history of the Robbins & Lawrence Company begins about 1838, when Lawrence came to Windsor from the neighborhood of Watertown, N. Y. N. Kendall & Company, was regularly making guns at the Windsor prison. They hired him at once for two years at $100 a year. In 1843 Kendall and Lawrence hired a small shop in Windsor village and started a custom gun shop. In the winter of 1844 S. E. Robbins, a businessman, came to them and said that the Government was in the market for 10,000 rifles. The matter was talked over, a partnership formed, and a bid sent to Washington. In spite of the opposition of nearly all the other Government contractors, who said they could never do the work, it resulted in the award of a contract for 10,000 to Robbins, Kendall & Lawrence, at $10.90 each, attachments extra, to be furnished within three years. They bought land, built a shop, and bought or made the necessary machinery. It was in the performance of this and the subsequent contract that many of the early machine tools were developed. Robbins & Lawrence Co. was formed in 1850 by Samuel E. Robbins and Richard S. Lawrence as a reorganization of Robbins, Kendall & Lawrence. In all of their gun work, Robbins & Lawrence used the interchangeable system, and they contributed very largely to its development. Lawrence, Howe, and later Stone, were constantly improving the methods of manufacture. Fitch's article on Interchangeable Manufacture in the U. S. Census Report of 1880, describes and illustrates a profiling machine built by Howe as early as 1848. The design shown there was used for many years throughout all the gun shops in the country. He also designed a barrel drilling and rifling machine, and he and Lawrence designed and built a plain miller, which was the forerunner of the well-known Lincoln miller. They began selling the machine tools used for making guns as a secondary product. One of these millers, built in 1853, is still running in the shop of the North Brothers Manufacturing Company in Philadelphia. This machine had a rack-and-pinion feed for the table, which chattered badly when starting a heavy cut. The principal improvement, which F. A. Pratt introduced in the Lincoln miller was the substitution for this of a screw and nut. The firm failed in 1856 and the plant and equipment were bought in 1859 by Ebenezer G. Lamson, who then organized Lamson, Goonow & Yale. This later became E. G. Lamson & Co., Windsor Mfg. Co. (1865), Jones, Lamson & Co. (1869) and Jones & Lamson Machine Co. in 1879. The original drawing of this Robbins & Lawrence machine is still on file in the office of the Jones & Lamson Machine Company and shows clearly that it furnished the basis of the design of the Lincoln miller. In 1889 the present Jones & Lamson Machine Company moved to Springfield, Vt., where it now is. That same year, James Hartness entered the employment of the company as superintendent. With his advent the scattering of activities ceased and the Jones & Lamson Machine Company began concentrating on turret lathes, which Robbins & Lawrence and their various successors have been manufacturing continuously since the early fifties. A number of the old mechanics and foremen, who had homes in Windsor at the time the company was moving to Springfield, took over the old shops and organized the present Windsor Machine Company which now manufactures the Gridley Automatic Lathes.

Three brilliant mechanics, Richard S. Lawrence, Frederick W. Howe and Henry D. Stone, were working there in the early fifties, and from them and their successors came wholly, or in part, the vertical lathe turret, the miller, the profiler and a large number of the modern machines used in interchangeable manufacture.

Information Sources

-

English and American tool builders By Joseph Wickham Roe 1916

-

American Lathe Builders: 1810-1910 by Kenneth L. Cope, 2001