Wickes Brothers, a partnership of Henry, Edward, and Charles Wickes, made reciprocating sawmills from about 1870 to at least 1954. The specialized in gang sawmills. In the early 1900s the also made heavy engine lathes, and after that time they specialized in crankshaft lathes that for the automobile and heavy engine manufacturing industry.

By 1954, Wickes Brothers was a division of Wickes Corp. Another Wickes product line, stationary boilers, had by this time already been spun out into a separate line of business, Wickes Boiler Co.

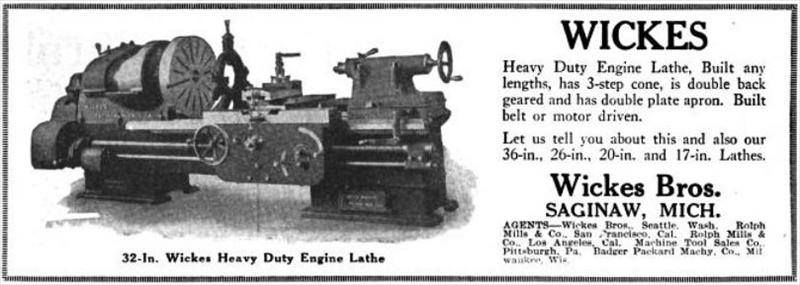

From 1919-01-02 American Machinist

Information Sources

- Robert Grimshaw's famous 1882 book, Saws, includes a picture of a Wickes Bros. gang sash saw.

- Industries of the Saginaws, by J. W. Leonard, 1887.

Wickes Brothers.—Manufacturers of the Celebrated Wickes Gang, and All Kinds of Heavy Mill Machinery; 512 North Water street, East Saginaw.—This prominent and representative firm was originally established in 1860 by Messrs. Henry D. and Edward N. Wickes, who were later joined by Messrs. Harry T. and William J. Wickes, these four gentlemen now composing the firm. Their machine shop is 130x50 feet in dimensions, with an L 60x70 feet. It is completely outfitted with all the latest and most improved machinery adapted to the business, including twelve lathes, the largest of which will take a 28-foot shaft, a boring mill with a 78-inch wheel, ten large planers, hanging and rotary drills, swinging tables,' stationary and traveling cranes, etc. Their foundry, which is a continuation of the L, is 60x80 feet in dimensions, and has the largest cupola in the State, holding eight tons. Their pattern shop, in which they carry a large and complete stock of patterns, is a two-story building, 50x75 feet, and their offices and mill supply department occupy a two story building, 65x50 feet, with a large warehouse and shipping department in the rear. Here they deal in and carry large stocks and full lines of everything in mill supplies, wrought iron pipe fittings for steam, gas and water, belting, packing, steam pumps, governors, inspirators and all steam heating apparatus. Their works, with a large yard in the center, cover about a block, and they have an extra warehouse for surplus stock further up the street. Employment is given to a force of one hundred hands, and in their works they manufacture all kinds of heavy mill machinery, making a specialty of the Wickes' Improved Iron Frame Gang Mill, which is so designed and proportioned as to insure durable and continued movement at the highest speed, safely increasing the quantity and improving the quality of work done, and admitting at the same time of the use of thinner saws and the carrying of heavier feed than is practical in other machines. This mill has obtained the approval of lumber manufacturers in all parts of the Union and Canada where lumber is cut, and occasional orders are also received from foreign countries. Over 300 of these mills are now in use, and the firm enjoys a constantly growing patronage as the merits of their mills become known over a wider range. All the operations of the works are conducted upon perfect and accurate system, and the firm enjoys the approval of the trade, as a result both of the merit of their work and the reliable methods upon which their dealings are conducted.

- Patents provided the names of the brothers and give evidence of what products they made, plus they provide data points spanning 1872 to 1954. A 1954 patent is assigned to "Wickes Bros., a division of Wickes Corporation, Saginaw, Mich." Subsequent patents are assigned to Wickes Corp.

- Directory of Metalworking Machinery, 1951, pg. 47