|

|

|

William Sellers

|

Coleman Sellers

|

The house of William Sellers & Co. was started in 1848 as

Bancroft & Sellers, and so continued until 1855, when upon the

death of the senior partner the business passed into the hands of two

brothers, William Sellers and John Sellers Jr., who alone constituted

the firm until 1873. It was the pioneer in the introduction of the

present system of mill-gearing with interchangeable parts, and the

manufacture of machinists' tools as a distinct branch of business.

When Edward Bancroft died, William, partnered with his brother, John, reorganized Bancroft & Sellers into this firm in 1855. Their cousin, Coleman Sellers, joined the firm in 1856 after having been superintendent at Niles & Co.

The focus was on large machine tools for the railroad industry. Sellers

built one of the largest lathes ever made in 1892 to turn and bore

barrels for the Navy's 16" guns.

In 1943 a group of investors bought William Sellers & Co. and merged it with Consolidated Machine Tool Corp. of Rochester, NY.

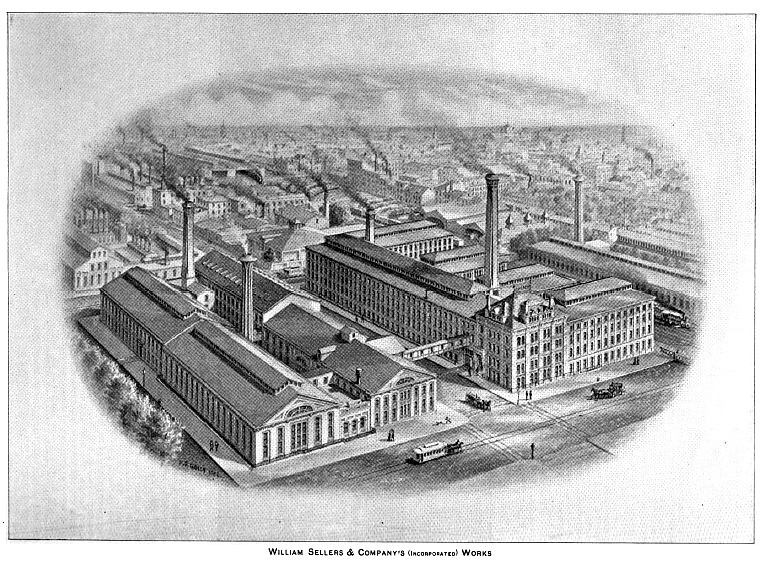

William Sellers & Company (Incorporated)

At the great iron works of William Sellers & Company

(Incorporated), Philadelphia, manual skill in a large measure is

dispensed with as there arc various machines for turning, planing,

shaping, drilling, or boring metal or wood in which the tool or cutting

edge is guided in its fixed path by mechanical means. The term "machine

tool" in this connection should be understood to include all machines

that work or shape metal, as steam hammers, hydraulic forging machines,

riveting machines, punching and shearing machines. As a distinct branch

of industry, "machine tool " making is of recent date. The first man to

attempt the construction of "machine tools" was Mr. Joseph Whitworth, of

England. Not long after this Bancroft & Sellers, now William

Sellers & Co. (Incorporated), started a similar establishment in

this country. They began in 1848 with the making of "machine tools"

shafting and mill gearing, their shops being located in Kensington, in

1853 they erected new buildings at Sixteenth and Seventeenth streets,

Pennsylvania avenue and Hamilton street, the works taking in the entire

block.

In 1855, not two years after the occupation of the new

works, Mr. Bancroft, the senior partner, died, and the business passed

into the hands of William Sellers and John Sellers, Jr., the firm name

being William Sellers & Company. The two brothers constituted the

firm until 1873, when Coleman Sellers,

John Sellers Bancroft and

James C. Brooks, who had long been associated in the business were

admitted to partnership. In 1870 they removed to new buildings covering

more than half the square of ground north of them, all that pertained to

the foundry, namely: the pattern shop, pattern storage rooms, and the

foundry proper. In addition to the regular business of the house of

"machine tool " making, they have for several years been engaged in the

manufacture of other necessities of railroads, as turn tables for

locomotives, turn tables for pivot bridges, sliding or transfer tables.

Their cast iron turn table has been adopted by many of the railroads in

the United States, South America and Austral1a, and is in use in Europe.

Among the most important of their recent productions arc two high speed

power travelling cranes just placed in the new erecting shops of the

Baldwin Locomotive Works. Each of these cranes has two 50-ton trolleys,

making the total capacity of each crane 100 tons. The machinery is

driven by electric motors and the speed of the cranes is as follows:

Upon the runway 100 and 200 feet per minute; transversely in the crane

bridge 50 and 100 feet per minute; hoisting and lowering 5, 10, 20, and

40 feet per minute; all variable at the will of the operator to any

speed between maximum and zero and may be made without shock or jar.

This house introduced the Gifford boiler injectors into the United

States, and improved it greatly, and is now sending the improved

instruments in large quantities to the French railways. The first

display of the work of this house in Europe was in Paris in 1867. This

they followed by a larger exhibit in Vienna in 1873. In Paris they

received the Gold Medal, and in Vienna what is called the Great Diploma

of Honor, the highest possible mark of appreciation. The award was to

"Sellers for pre-eminent achievements in the invention and construction

of 'machine tools,' many of which have been adopted as patterns by the

constructors of tools in all countries."

With the advent of "machine tools," wooden cog wheels,

wooden shafts, and the cumbersome wooden drums gave way to iron pulleys

on iron shafts, running in metal boxes. But all those were of clumsy and

heavy designs, altogether too heavy, and as they were sold at so much

per pound, there was small inducement for the manufacturer to attempt a

reducement in weight. The need of a more perfect system of transmission

had long occupied the mind of Mr. Edward Bancroft, and at last he

designed a form of hanger for shafts which is known as the "ball and

socket hanger," and is now in general use throughout the country. It

involves a self-adjusting principle in the alignment of the box in

relation to the shaft turning in it and ready means of lining up the

entire series of shafts, making one continuous line. Oddly enough after

this invention was completed, Mr. Bancroft could not induce a single one

of the leading manufacturers to take hold of it. On this account the

house of Bancroft & Sellers pushed forward to further perfect the

manufacture of shafting, and soon became as celebrated for the

excellence of their shafting as for their other machines. In fact they

turned their attention very particularly to the shafting business and

they contrived many ingenious machines in this connection. They

1ntroduced a new form of coupling for uniting the separate pieces of

round iron going to make up a line of shafts. This coupling was easily

attached and detached, did away with much expensive fitting requiring

skilled workmen and allowed the use of a form of hanger with less metal

than was ever before possible. It took some time to show the users of

hangers that it would be true economy to pay more per pound for a good

article, that was honestly strong and would cost less money to keep

running and in repair than to buy, at say ten per cent, less per pound,

triple the number of pounds costing more coal to run. But eventually

this lighter and more efficient shafting was placed upon the market at

no greater cost in the aggregate than the other articles. This change

was due entirely to the introduction of improved "machine tools." Many

hundreds of miles of this improved shafting now drive the cotton and

woolen mills of this country, and there are numerous examples of it to

be found abroad.

In their exhibit in Paris in 1867, and

afterwards in Vienna, this new system of shafting was first displayed in

Europe. A number of the technical schools of Europe have purchased

samples of hangers, couplings, etc., which they have placed in the1r

museums. The foreign journals, while enthusiastic over the merits of the

hangers and couplings of this firm, declare that in their introduction

to Europe, much is due to the establishment of a scale of fixed prices

in contradiction of the custom of some other manufacturers, who, selling

their goods by weight, would make them inconsistently heavy. For

instance, the London Standard says, "The advantages thus arising to the

purchasers of the Messrs. Sellers' improved shafting consist not only in

a direct saving of first cost by greatly diminished weight, but in the

acquisition of a well constructed and smooth running shafting of very

neat appearance and as light as is consistent with the required

strength. The journal boxes are unusually long and so held in their

supports as to always insure a uniform distribution of pressure over the

entire length of bearing. In their construction iron is used instead of

brass or other soft metal composition."

Appended to the

report made by the British Commissioners to Parliament on the subject of

the Vienna Exhibition, there were a series of technical papers on

special sections of the Exhibition contributed by W. W. Maw and James

Dredge. Speaking of machine tools they say of the exhibit from the

United States, "For the number of machines it included there was in fact

no collection of tools in Machinery Hall which could compete for real

originality of construction with that found in the American department.

Messrs. W. Sellers & Company, of Philadelphia, are well known as the

Whit worths of America, and their exhibits well sustained their

reputation both for design and excellence of workmanship." One of their

machines which attracted perhaps the largest share of attention at the

European exhibitions was a peculiar kind of planing machine for metal.

It was the invention of Mr. William Sellers and involved an entirely new

principle in the method of operating the table. A shaft crossing the

bed diagonally has on it a spiral pinion, this pinion engages the teeth

of a straight rack and imparts an exceedingly uniform motion to the

table with less friction than is common to other methods of driving.

This machine has been greatly improved of late years and is now as far

in advance of the ordinary constructions of planing machines as the

original invention was of the machines then in use.

Another

of the English journals speaking of the planing machine for metal, said,

"The American inventor had in v1ew the construction of a better machine

than any now in use and that could be more economically placed in the

workshop. The English builder of what purported to be the same character

of tool, adapted devices which had been found to work well but ignored

all the deviations from existing customs that looked towards a rational

change in the placing of tools in the work shop. American mechanics have

been obliged to bestir themselves in the world's race. They have had to

contend with high wages and a lack of good workmen, they have therefore

been forced to exercise their inventive faculties to make machinery

that will cheaply and effectively perform the work required to be done,

and this house held to be a model in its line, has done its share in

this great work by its perfection of the tools required to make these

machines."

William Sellers & Company (Incorporated) are

now engaged among other works in building the large gun lathes for the

United States Navy Yard, Washington, for 16 and 14 inch rifled guns.

These are not only of the largest that have ever been designed for such

uses, but embody features which in the judgment of engineers make them

superior to any lathes before produced for modern guns.

Many

of the machines above mentioned have been recently greatly improved,

and there have been added several important tools, among them the tool

grinding and shaping machine, and the drill grinding machine with drill

pointing attachment. This great industrial works was incorporated in

1886, and is now presided over as follows: William Sellers, president

and engineer; John Sellers, Jr., vice-president and treasurer; Justus H.

Schwacke, secretary; J. Sellers Bancroft, manager; D. L. Lukens,

purchasing agent.

William Sellers Obituary

Mr.

Sellers was born in Upper Darby, Delaware County, Pa., September 19th,

1824. He was educated at a private school maintained by his father and

two relatives for the education of their children, and served his

apprenticeship at the machinists' trade with his uncle, John Morton

Poole, of Wilmington, Delaware, for nearly seven years. In 1845 he took

charge of the large machine shop of Fairbanks, Bancroft & Co., in

Providence, R. I. In 1848 he commenced the manufacture of machinists'

tools and mill gearing in Philadelphia, and subsequently joined Edward

Bancroft. The new firm was Bancroft & Sellers. Later John Sellers,

Jr., was admitted as a partner, and in 1853 the new shop at 16th Street

and Pennsylvania Avenue was occupied. Mr. Bancroft died about 1856, and

the firm became William Sellers & Co. Finally, in 1886, the company

was incorporated with William Sellers as president. In 1868 he formed

the Edgemoor Iron Co., of which he was president. This company furnished

all of the iron structural material for the Centennial Exhibition

buildings, and also all of the structural material for the Brooklyn

Bridge, with the exception of the suspension cables. In 1873 Mr. Sellers

became president of the Midvale Steel Co., Nicetown, Philadelphia, Pa.,

which he reorganized and which under his management became the first

successful producer of material required by the Government for its steel

cannon.

In 1868 he became a member of the Board of Trustees

of the University of Pennsylvania, and served continuously until the

time of his death.

In 1864 Mr. Sellers was elected a member

of the Philosophical Society, and in 1873 became a member of the Academy

of Natural Sciences; he was a member of the Institute of Mechanical

Engineers of Great Britain, the Iron and Steel Institute of Great

Britain, a corresponding member of the Societe d'Encouragement pour

L'Industrie Rationale, in Paris, and at the close of the Paris

Exposition, in 1899, the decoration of Chevalier de la Legion d'Honneur

was conferred upon him. He was also a member of the American Society of

Civil Engineers and of this Society, having been one of its founders in

1880.

Mr. Sellers was granted about ninety United States

patents, the earliest one having been in 1857, and some were pending at

the time of his death. A great variety of subjects were covered,

including machine tools, injectors, rifling machines, riveters, boilers,

hydraulic machinery, furnaces, hoists, cranes, steam hammers, steam

engines, ordnance, turn tables, pumps, etc.

Probably the

best known of his inventions is the spiral gear planer drive, in which

the table is moved back and forth by a multi-thread screw on an inclined

shaft engaging with a rack on the under surface of the table.

In 1847 Mr. Sellers was elected a member of the Franklin Institute.

He served as a member of the Board of Managers from 1857 to 1861 and

again from 1864 to 1892. He served as president from 1864 to 1867.

As chairman of a special committee of the Institute, he formulated a

uniform system of screw threads which was presented to the Institute at

a meeting on September 15th, 1864.

This report was approved

by the Institute, and within a few years was adopted by the Government

in its workshops by the leading railroad companies, prominent machine

tool builders and others, under the various names of the United States,

Sellers, or Franklin Institute Systems.

The leading

difference between the Sellers and Whitworth forms lies in the angle of

the thread and in the fact that it has a flat top and bottom instead of

being round. In 1890 the Navy Department at Washington sent out

specifications to machine tool builders for an eight-foot turning and

boring lathe for sixteen-inch steel cannon. The main bed was nine feet

wide and over seventy-three feet long, the extension bed for the boring

arrangement was about fifty-three feet long and five feet wide, making a

total length of over one hundred and twenty-eight feet.

Mr.

Sellers did not approve of the Government design and refused to bid,

but he had a complete new design made, and convinced the Board of

Engineers at Washington of the superiority of his design, which they

adopted, discarding their own. Mr. Sellers received the contract for

this lathe, which weighed about 500,000 pounds. In 1S60, during a visit

to England, his attention was called to the Gifford injector for feeding

steam boilers. The device was crude, but Mr. Sellers saw in it the

elements of a novel principle. He secured the American rights and

commenced the manufacture of these injectors, which he slightly

modified, however. In 1865, after various improvements, he invented and

patented the self adjusting combining tube which automatically adjusted

the supply of water to meet the requirements of varying steam pressures.

Further developments led to the most advanced and satisfactory forms of

locomotive injectors.

Mr. Sellers died January 24th, 1905, in the 81st year of his age.

Information Sources

- American Lathe Builders: 1810-1910 by Kenneth L. Cope, 2001

- American Milling Machine Builders: 1820-1920 by Kenneth L. Cope, 2007

- American Planer, Shaper and Slotter Builders by Kenneth L. Cope, 2002

- Transactions of the American Society of Mechanical Engineers American Society of Mechanical Engineers, 1905

- Philadelphia and popular Philadelphians by The North American, 1891

- A treatise on machine-tools, etc. as made by Wm. Sellers and Co By William Sellers & Co. (Philadelphia, Pa.), 1877

- Vitiello, Domenic. Engineering Philadelphia. New York: Cornell University Press, 2013.