Manufacturers Index - Essex & Smith; Winfield H. Smith

Essex & Smith; Winfield H. Smith

Buffalo, NY; Springville, NY, U.S.A.

Company Website: https://www.winsmith.com/

Manufacturer Class:

Metal Working Machinery & Steam and Gas Engines

Last Modified: Feb 12 2022 11:24AM by Jeff_Joslin

If you have information to add to this entry, please

contact the Site Historian.

|

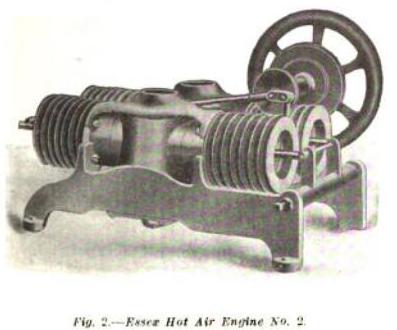

W. H. Smith Manufacturing Co. was manufacturing a hot air engine that had been patented in 1903 by Henry Essex of Buffalo.

|

| From article in 1905-02-02 The Iron Age. The manufacturer was W. H. Smith Manufacturing Co. See Publications tab to view the full article. |

In mid-1907 the Essex & Smith Co. was organized to succeed the earlier business; the incorporators were Henry Essex, Winfield H. Smith, and J. J. McMaster. Their factory was located at 6-8 Lock Street in Buffalo.

|

| From 1909-09-25 Scientific American |

Essex & Smith manufactured their hot air engine in sizes from 1/32 HP to 1/4 HP. They also manufactured products powered by their engines, namely a desk fan and a moving store display fixture. They were also manufacturing and selling grinding and polishing heads.

Essex & Smith continued in business until about 1912 when they dropped from sight. We completely lose track of Mr. Essex at this point. As early as June 1913 Winfield H. Smith was advertising hot air engines plus a new line of grinding and polishing heads; he was operating from the same Lock Street premises that had been used by Essex & Smith. Within a year or so Smith's ads no longer mention the hot air engine. By 1916 arbor presses had been added to the lineup. Speed-reduction gearboxes gradually became the primary product line. In 1916 Smith relocated to new facilities at 10-16 Lock Street. By 1919 a lineup of small pulleys, hangers, and pillow blocks had been added to the lineup.

At some point Smith established a manufacturing operation at Springville, N. Y., and in 1924 the company headquarters moved to Springville, with the Lock Street premises remaining as their Buffalo office.

By 1950 the company was operating as the Winfield H. Smith Corp. and the company's main product continued to be speed reduction gearboxes. The arbor presses and grinding-polishing arbors were long gone by this time. The company remains in business as Winsmith, making speed reducing gearboxes and other gearing products.

Information Sources

- We learned of this maker from a discussion in an owwm.org forum.

- 1907-06-29 The Industrial World, in their column on "New Incorporations".

Essex & Smith Company, Buffalo, N. Y.; to manufacture hot air engines, etc.; capital, $20,000; incorporators, Henry Essex and Winfield H. Smith, Buffalo, N. Y.; J. J. McMaster, Rochester, N. Y.

- 1907-07-04 The Iron Age.

Motors and Small Engines—The Essex & Smith Company has been incorporated at Buffalo, N. Y., with a capital stock of $25,000, to take over the business of the W. H. Smith Mfg. Company, and to manufacture the Essex patent hot air engines for light power purposes, operated with gas, gasoline, kerosene or alcohol as fuel. The company has equipped a factory at 6 and 8 Lock street.

- 1907-09-28 Domestic Engineering.

The Essex & Smith Company, of Buffalo, N. Y., has been incorporated to take over the business of the W. H. Smith Manufacturing Company and continue the manufacture of hot air engines.

li>1909-09-25 Scientific American: small ad with illustration: "Essex Hot Air Engines / Small sizes, 1/32 to 1/4 H. P. / Ideal for Light Power Purposes / Write us for Catalogue / Essex & Smith Co. / 6 and 8 Lock Street, Buffalo, N. Y."

- 1909 Buffalo Directory lists "Smith Winfield H treas Essex & Smith Co r 76 Johnson's pk".

- 1910-07-16 Metal Worker, Plumber and Steam Fitter.

A desk fan without electricity is a product which can be obtained from Essex & Smith Co., 6 Lock street, Buffalo, N. Y. An idea of its appearance and construction is obtainable from the accompanying illustration. Its motor is a little air engine, running by the simple expansion and contraction of air and is directly connected with a 16-in. fan on the engine shaft, as shown. A flame of gas, alcohol or gasoline suffices to expand the air and forces out the piston of the motor. The air is then contracted by the cooling effect of the fan, and the air is drawn back into the cylinder, thus completing a revolution of the fan. The expansion and contraction takes place every revolution of the motor, and the speed at which the fan revolves shows the quickness with which the operation is performed. It is, of course, to be remembered that there are no explosions and no odoriferous exhaust, as the products of combustion are simply those incident to the burning of the fuel, such as gas or alcohol, as stated. The outfit is certainly an ingenious affair, and of course has the advantage that it can be used where electricity is not available. The company makes air engines of larger size, especially for driving window display novelties where motion of the display is desirable for attracting notice. In this case is supplies, for example, what may be called a Ferris wheel, a wheel revolving slowly and carrying a number of trays, which can be brought successively forward toward the front of the window for carrying displays of small articles.

- 1911 Engineering Directory lists "Essex & Smith Co., Buffalo, N. Y." under the categories of "Engines, hot air pumping" ("Essex Engine"); "Heads, Grinding and Polishing"; "Motors, Air" ("Essex / fan"); "Motors, Water" ("Niagara").

- 1911 Iron Age Directory lists "Essex & Smith Co., Buffalo, N. Y." under "Engines, Hot Air", "Fans, Air Motor", "Heads, Grinding", "Heads, Polishing", and "Window Display Revolving Devices".

- June 1913 Gas Power, classified ad: "Big money in Essex Fan Motors, run by gas or gasoline. Winfield H. Smith, 6 Lock Street, Buffalo, N. Y."

- 1912-07-05 The Hardware Reporter lists Essex & Smith Co., Buffalo, N. Y., as makers of "Fans—Motor".

- 1913 Annual Industrial Directory of New York State lists Essex & Smith Co., 6 Lock, makers of hot air engines, 9 employees in the factory and 1 in the office.

- July 1913 The Metal Industry has an illustrated article.

Polishing and Grinding Heads

Winfield H. Smith, 6 and 8 Lock street, Buffalo, N. Y., is putting on the market a line of polishingn and grinding heads especially suitable for manufacturers of jewelry and small metal goods, and which he claims are unequaled as regards design, workmanship and finish...

- December 1914 Technical World, in the Classified Ads section "Manufacturing". "I can manufacture your device to your advantage. Write me. Winfield H. Smith, Manufacturer, Buffalo, N. Y."

- April 1915 Steam, in a listing of new catalogs. "Winfield H. Smith, Buffalo, N. Y. Leaflet presenting the Common Sense Flue Cleaner."

- 1916 issue of Mill Supplies (vol. 6 p. 71).

Winfield H. Smith, Buffalo, N. Y., manufacturer of the "Common Sense" flue cleaner, arbor presses, polishing and grinding heads, speed reducing gears, small transmissions for display fixtures, etc., has removed from 6-8 Lock street to 10-16 on the same street, where he has greatly improved manufacturing facilities and increased space.

- 1919-05-24 Electrical World, in a listing of trade publications.

Pulleys.—Pulleys, hangers, pillow blocks, arbor presses, reducing gears and revolving display tables are cataloged in a booklet issued by Winfield H. Smith, 10 Lock Street, Buffalo, N. Y.

- July 1922 Popular Mechanics, classified ad.

Power attachments for Ice Cream Freezers, $7.50. Can be attached to any hand freezer. Gives the right reduction between motor and freezer. Winfield H. Smith, Buffalo, N. Y.

- March 1924 Engineering World.

Catalog No. 21 of Winfield H. Smith is a New One.

Winfield H. Smith, manufacturer, Buffalo, describes in Catalog 21, grooved and crown faced pulleys, hangers, pillow blocks, arbor presses, reducers, revolving display tables and power attachments for ice cream freezers.

The catalog is illustrated with cuts of the various articles manufactured by this house.

- 1924-09-11 American Machinist.

Winfield H. Smith, machinery manufacturer, announces the removal of his factory from 10-16 Lock St., Buffalo, N. Y., to Springville, N. Y. A Buffalo office will still be maintained at the old address.

- 1924—From a a page at the Town of Concord, NY, Historical Society site: "Winfield H Smith Inc. (Pulley Works) moves from Buffalo in September to their new Factory in Springville." This event is listed for the year 1924.

- December 1925 Western Machinery World, ad from "Winfield H. Smith Springville, N. Y. (formerly Buffalo, N. Y.)" for "Smith Speed Reducing Gears", a worm-drive gearbox for motors up to 3 HP, available in multiple sizes, though unspecified in the ad.

- November 1937 Modern Machine Shop has an ad from the Formica Insulation Co. for "Formica" gear cutters; among the numerous representatives listed is Winfield H. Smith, Inc. / Springville, N. Y.

- 1941 issue of Concrete (vol. 49, p. 147). "Winfield H. Smith Brings Out New Speed Reducer, N. Y., near Buffalo, recently brought out an additional speed reducer, said to be designed for continuous-duty installations. The worm of this unit is of hardened steel and has ground threads. It is located on top Rubber Soles and Heels installations requiring high mounting heights; and is available for operation on..."

- 1950 issue of Industry Week. "Winsmith-Buffalo, Marine Trust Bldg., Buffalo 3, is appointed representative by Winfield H. Smith Corp., Springfield, N. Y., manufacturer of speed reducers and gears. Winsmith-Buffalo is a new company under the management and proprietorship of L. D. Aydelotte, former sales manager of Winfield Smith. Sales territory of the new company will include all of New York State outside metropolitan New York City, as well as Erie, Crawford, Warren and McKean counties in Pennsylvania..."

|