|

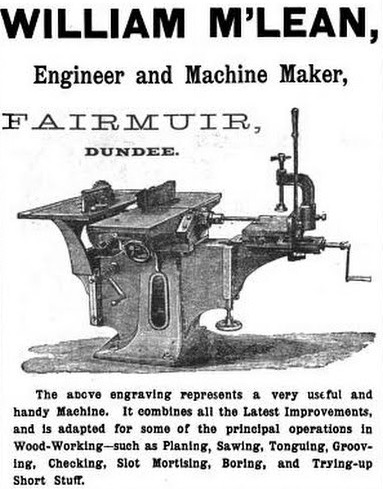

| Ad from 1892-09-10 Timber and Wood Working Machinery |

Beginning in 1878 William McLean manufactured woodworking machinery and small steam engines among other products. The business eventually became William McLean & Sons, Ltd., and continued until 1972.

Information Sources

- 1878 Birmingham Post Office Directory, page 203, Advertisement: "William McLean, Fairmuir Machine Works, Dundee, Engineer & Machine Maker, Manufacturer of all kinds of Boot and Shoe Manufacturers' Machinery. Bread and Biscuit Machinery of First-Class Construction. Steam Engines from 1 to 10 H.P.; Band Saws, Saw Benches, &c., &c."

- 1882-01-14 The Furniture Gazette. "Woodworking: Machinery.—The other day we had an opportunity of inspecting some of the woodworking machinery manufactured by Mr. William McLean, of Fairmuir, Dundee. His manufactures include band-saw machines, circular-saw benches, tenoning, and drilling machines, &c. Most recent improvements are embodied in these machines, and they are produced at prices which enable Mr. McLean to successfully compete with other makers. The fact that many of his machines have been supplied to English firms in different parts of the country, and also to continental houses, speaks well for the quality of his productions."

- Grace's Guide page on William McLean.

- Ad in 1892-09-10 Timber and Wood Working Machinery for "William M'Lean, Engineer and Machine Maker, Fairmuir, Dundee." Pictured is a combination machine with table saw, horizontal mortiser/borer and jointer-planer.

- A page at the Dundee Industrial Heritage website shows a drill press from "William McLean and Sons Ltd. Founded in 1878 and based at Fairmuir Street, this company manufactured engines and machinery until 1972."

- 1956 issue of Transport (Volumes 6-7, page 16).

NEW PROCESS VIRTUALLY CUTS OUT NEED TO OIL MACHINERY Scottish Engineer Perfects Novel Technique A NEW process for treating metal surfaces has been invented in Britain which enables machinery to run almost indefinitely without the moving parts in need of oil or grease...

...It is claimed by testing experts to be "the most important development in engineering since the introduction of steel."

The new process, known as 'Promac', is the invention of a Scottish engineer named John McGregor. In the pioneering and the fitting of treated parts in various industrial establishments in the area, the inventor was helped by the Dundee engineering firm of William McLean & Sons. Of the many applications of the Promac, one spectacular test was carried out at a jute factory in Dundee where tests on the spindles of a jute loom began on February 22. It is now reported that not one drop of oil was needed to be applied to the spindles in all that time, while the oil requirement of normal loom spindles is once every two hours. An experiment is now to take place with a shuttle where one of the major results is expected to be the lessening of factory noise.

Motor-car Tests

Several Edinburgh buses have been fitted with Promac-treated parts, and among the notable results reported were easy starting from zero temperature, quieter running, and about two miles more to the gallon of fuel. Another test is claimed to have shown no measurable wear to a motor-car engine after 20,000 miles' running, and in another, car lubricating oil was still quite clean after 70,000 miles. Revolving parts, such as roller and ball bearings, have run higher speeds than usual without oil and without any signs of wear. Mr. McGregor, who has patented the Promac process, has been responsible for a number of previous inventions and has worked for several engineering companies but resigned to give himself more time for research.

Officials of William McLean confessed, according to press reports, that at the outset the were sceptical about the Promac process, but it is now the opinion of their qualified engineers that the process have been proved beyond doubt.

- 1979 book The City of Dundee, page Joseph M. Jackson. From page 145.

William McLean and Sons. A general engineering concern was William McLean and Sons. Specialists in project tool installation and maintenance work, the firm undertook machining, fabrication, welding, metal spraying and machine tool rebuilding. An interesting new product was an electrical device which was designed to speed up and ensure better machine-utilisation of jute spreaders. (The spreader is the machine which teases out the jute fibre, and in guiding the machine the operator previously had to try to co-ordinate two pointers. With the new device she had only to keep an eye on one pointer which showed the supply of jute as 'too light' or 'too heavy'. The prototype devices were built by the British Jute Trade Research Association and when demand appeared to justify their manufacture on a commercial scale, the Research Association approached William McLean.