|

| From August 1900 The Canada Lumberman |

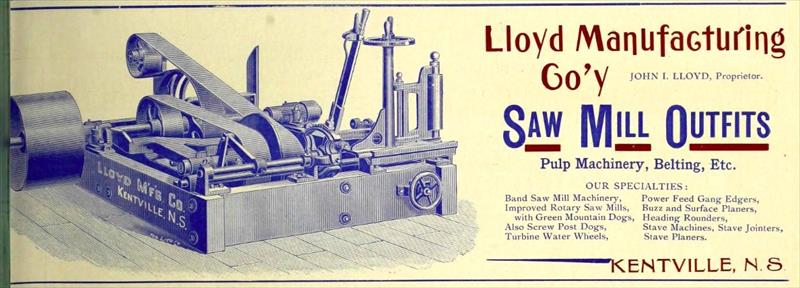

John Lloyd's Foundry and Machine Shop was established in 1881, and made marine engines and sawmill machinery. The name became the Lloyd Manufacturing & Foundry Co. at some point, and in 1895 it became Lloyd Manufacturing Co. making engines and sawmill machinery: band and circular sawmills, gang edgers, planers, jointers, and cooperage machines. At some point the business became W. J. Burrell's Machine Shop and Foundry.

Lloyd licensed the Lane shingle-machine design and manufactured it for the Canadian market.

Information Sources

- A university class research report, An Examination of Kentville’s Environmental History (PDF).

Another prominent industrial business in Kentville was Lloyd's Foundry, founded in 1881 by John I. Lloyd and incorporated in 1895 as Lloyds Manufacturing Company. Located on River Street,Lloyd's was Kentville's first dedicated foundry and machine shop and produced a wide array of industrial tools and manufacturing parts. These included gas engines, barrel making equipment, gold mining machinery, pulp machinery, belting, and saw mill outfits. By 1913, Lloyd's consisted of a machine shop, a foundry and a carpenter shop. As a facilitator of commercial and industrial production, the company was intrinsically linked to the creation of secondary industry within the town. A perfect example of this would be Lloyd's short but important relationship with the McKay Car Company. Early on in the production of the McKay automobile it was discovered that the drive shafts for the cars were all too short. Lloyd's foundry was subsequently contracted to make shafts of the appropriate dimensions and the cars were completed.The presence of a skilled and important local foundry saved the McKay brothers the costly and time-consuming process of reordering drive shafts from their sources in the United States. While much of the foundry's early business was to local town customers and surrounding farmers, Lloyds also engaged in an extensive export business. The Bridgetown Monitor reported that in a single week in 1895, Lloyds exported $1000 worth of machinery to different parts of the province and expanded their operations from seven employees to fourteen. From 1881 to its closure in 1987, Lloyds exported machine parts and industrial components to many Nova Scotia communities as well as to other Canadian locations in New Brunswick, Quebec, Vancouver, and Newfoundland.

Fire has played an important part in the history of Lloyd's foundry with at least 3 major fires since its inception. The first two fires were in 1890 and 1900 and both caused extensive damages to both the structure and equipment. In 1935 the foundry was purchased by Winslow J. Burrell and became the Burrell Foundry and Machine Works. During World War II, the Burrell Foundry was heavily involved in the maritime war effort producing naval equipment such as racks for the storage and deployment of depth charges.15 The foundry was also involved in modernization of the valley's dikes and marshlands. The Maritime Marshland Reclamation committee commissioned the Burrells to create brass sluices which were then used to replace the ones used by the original Acadians.

It was under Burrell's ownership that the site suffered its third and worst fire in 1967 which resulted in the destruction of the foundry and damaging of the machine shop. The foundry was not subsequently rebuilt but the business continued to operate until 1987. Courtney Burrell, Winslow Burrell's son, recalls that reasons for the eventual closing of the business were linked to a decrease in business, a lack of qualified employees, and the wish to retire expressed by the Burrell family. In our conversation with Mr Burrell, he mentioned that companies that usually would have required the services of their machine shop had begun to implement their own in-house shops. They no longer required the services of a third party and therefore the Burrells business suffered. In addition, the creation of the Annapolis Valley Industrial Park was likely source of competition as much as it was business. Courtney Burrell also mentions that the family's health has been affected by their work within the foundry. Decades of exposure to industrial pollution and exhaust have left him and other members of the family with various health issues. The lack of safety and health knowledge associated with pre- contemporary industrial production is responsible for the Burrell families affected health. Modern industrial production in Kentville is subject to extensive government regulation in order to minimize the negative long term health effects.

- Information on the Lane shingle mill comes from a research report on shingle machines in BC by Robert Griffin of the British Columbia Provincial Museum.

- January 1900 The Canada Lumberman: "An unfortunate occurrence was the destruction by fire, on January 11th, of the foundry and machine shop of the Lloyd Manufacturing Co. at Kentville, N.S. The loss is estimated at $15,000, but there were about $8,000 worth of orders on hand at the time of the fire. It is understood that the works will be rebuilt as soon as possible."

- 1920-21 Canadian Trade Index lists Lloyd Mfg. Co. of Kentville, N.S., as makers of gas and gasoline engines; hoisting machinery; pulpwood and pulp machinery; saw, shingle and planing mill machinery; and winches.