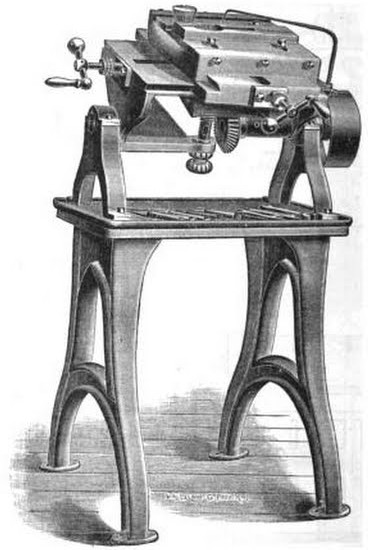

The Thurston Manufacturing Co. was established in 1883 by Horace Thurston. In 1891 they began manufacturing a patent machine—the Thurston & Schott Inverted Milling Machine—that was specialized for making dies for stamping small parts from metal sheets. Their primary markets were manufacturers of jewelry and guns. By 1902 the company was also making a filing machine. As of 2018 the company remains in business, making thin cutting blades for specialized applications.

The "Schott" of the "Thurston & Schott Inverted Milling Machine" was John C. Schott, who was a partner in the Providence, RI, firm Schott Brothers, which manufactured button-making machinery.

|

| The Thurston & Schott Inverted Milling Machine, from article in 1891-07-16 The Iron Age |

Information Sources

- A report on Thurston Mfg. Co. building (PDF), by the Rhode Island Historical Preservation and Heritage commission, has the following.

Thurston Manufacturing Company, manufacturers of special milling machines, had been founded by Horace Thurston in 1883 at 419 Eddy Street (Simmons Building). Born in Norwich, Connecticut, June 17,1852, Thurston apprenticed at the Corliss Steam Engine Co. from 1869 to 1873; was employed by Providence Tool Co.; served as foreman for the Brown & Sharpe Manufacturing Co. for five years; and as master mechanic for the Cummer Engine Co. of Cleveland, Ohio for two years, prior to opening his own business. Thurston's milling machines, known as the Improved Thurston & Schott Inverted Milling Machine, were used for milling cutter plates and were considered the most economical machines ever put into a jewelry shop (Hall 190:104). In 1898, the Manufacturing Jeweler (quoted in the Providence Journal of Commerce Vol. VI, no.4:141) reported that the company had received many new orders for their improved inverted milling machines which are "better... for manufacturing jewelers and silversmiths than any other made." The company also manufactured a variety of saws, files, burrs, and cutting tools for clients all over the world.

The report notes that, at the time of the report's writing, the company was still in business, manufacturing thin cutting blades of high speed sheet steel, mostly special orders to customer specifications.