Manufacturers Index - Thomas Blanchard

Thomas Blanchard

Sutton, MA, Boston, MA, and New York, NY, U.S.A.

Manufacturer Class:

Wood Working Machinery

Last Modified: May 28 2015 5:09PM by Jeff_Joslin

If you have information to add to this entry, please

contact the Site Historian.

|

Thomas Blanchard was perhaps the greatest American innovator of automated woodworking machinery. He received 24 patents, mostly for woodworking machinery, covering aspects of circular saws, mortising machines, molding machines, and boring machines.

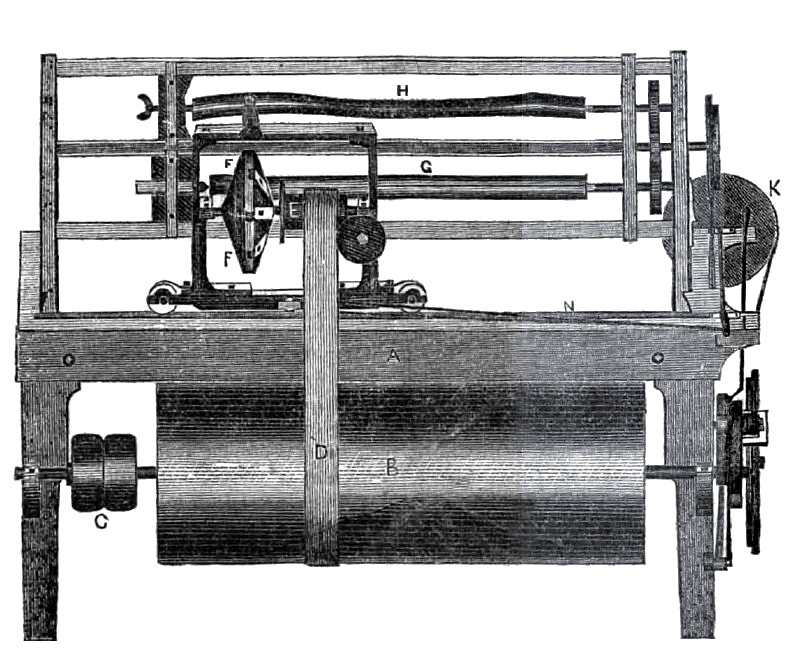

His greatest invention was his machine for turning irregular forms, originally patented in 1819 (no. X3,131), and extended until 1862. It was originally intended for gunstocks, but was subsequently used for axe handles, piano legs, cricket bats, shoe lasts, spokes, wig stands, and countless other irregular but smooth objects. Blanchard's machine used a slowly-rotating pattern to move the spinning cutter in and out as the work rotated in unison with the pattern; at the same time, the cutter and the pattern-follower gradually moved along the horizontal axis of the lathe.

Blanchard's machine for turning irregular forms, from 1848-09-09 Scientific American

Harper's magazine of 1856 said, "The idea of this beautiful and simple machine, which has received so infinite an application in our day, first occurred to Blanchard, it is said, as he was driving through a country town in New England [Brimfield, according to a version of this story in an 1847 issue of Scientific American]. In the excitement of the moment he shouted ["I have got it! I have got it!" in the Scientific American version], and sprang from his seat; attracting such attention that passers-by were half inclined to secure the person of so obvious a lunatic. Perhaps no American invention has challenged more admiration or provoked more piracy than his." Since then, many dozens of patents have granted to others who made embellishments to Blanchard's original idea.

Blanchard did much of his work on behalf of the Springfield Armory. Although he did make machines for others, he probably did not manufacture woodworking machinery in any volume.

Information Sources

- A biography of Blanchard is available: Shaping invention : Thomas Blanchard's machinery and patent management in nineteenth-century America, by Carolyn C. Cooper.

- From "Reports of Cases Arising Upon Letters Patent for Inventions, Determined in the Circuit Courts of the United States, Volume I" by Samuel S. Fisher, 1870:

Thomas Blanchard v. Biddle Reeves, Charles W. Reeves, Isaac B. Eldridge, et. al.", In September 1850, Blanchard asked for an injunction to stop the defendants from manufacturing a machine that allegedly infringed Blanchard's patent X3,131, granted 1820-01-20 and extended fourteen years by act of Congress. The case centered around the question of whether the defendant's machine did infringe on the patent. "Indeed the difference of opinion which appears in this case, seems to result from the construction given to the specification of complainant's patent, and in assuming that 'the only method proposed by Mr. Blanchard, is that in which the friction wheel or tram describes a spiral line over the whole surface of the model, and causes the cutters to act in a similar direction.'... Many of its parts may be changed or substituted by other mechanical equivalents or devices, which either improve or deteriorate its value, while the original idea, principle, or mode of operation of the inventor is manifestly preserved." Blanchard's invention is summarized: "The invention consists in arranging and combining together—1st, a model; 2d, a guide; 3d, a cutter-wheel; and 4th, a rough block, in such a manner, and under such relations that when the machine is in operation the guide shall be made to touch successively every part of the surface of the model, and that it shall, at the same time, govern the cutter-wheel, by permitting or causing it to advance or recede from the axis of the rough material, having, in this, a constant relation to the distance of the face of the guide from the axis of the model: by which means the cutters remove, by their own independent motion, from the rough block, every part of the same which projects into or beyond the line or path of the cutters in their revolution, so that the rough block is at length reduced to a certain conformity and resemblance in shape to the model." The defendants machine had all of these components, the difference being that the lateral (axial) feed was intermittent rather than continuous, so that the guide and cutter both move in a series of circles rather than in a continuous helix. "Such a change in the subordinate agents or devices, affecting the motions of the model and guide only in the figure of their path, or the relative lines of their movements, in no case changes the principle, essence, substance, or character of the machine...the defendants have pirated the invention of the complainant in all its essential parts." The request for injunction was upheld.

- The 1869-12-18 Scientific American printed this biographical sketch:

THOMAS BLANCHARD, who was born in Sutton, Worcester county, Mass., June 24, 1788. From a strong bias for mechanical employments, he joined his brother, who was engaged in the manufacture of tacks by hand, a very slow and tedious process, and at the age of eighteen commenced his invention of a tack machine. It was six years before he could bring it to the desired perfection. Finally, so effective was the machine, that by placing in the hopper the iron to be worked, and applying motive power, 500 tacks were made per minute, with better finished heads and points than had ever been made by hand. For this machine, Blanchard secured the patent, and sold the right to a company for $5,000. About this time various attempts were made in several of the United States armories to turn musket barrels with a uniform external finish. Mr. Blanchard undertook the construction of a lathe to turn the whole of the barrel from end to end by the combination of one single self-directing operation. He succeeded perfectly in his invention, and this remarkable machine with modifications and improvements, is in use in the national armories as well as in England; and in various forms is applied to many operations in making musket stocks, such as cutting in the cavity for the lock, barrel, ramrod, butt plates, and mountings, comprising, together with the turning of the stock and barrel, no less than thirteen different machines. Mr. Blanchard was also interested at an early day in the construction of railroads and locomotives, and in boats so contrived as to ascend the rapids of the Connecticut, and rivers in the Western States. He has took no less than twenty-four patents for different inventions, He died at Boston, April 17, 1864.

- The American Precision Museum has a biography of Thomas Blanchard.

|