|

Title: |

1911 Article-Yerkes & Finan Wood-Working Machine Co., 24 Spindle Dowel Boring Machine |

|

Source: |

St. Louis Lumberman, 15 May 1911, pg. 22 |

|

Insert Date: |

9/20/2014 1:15:07 PM |

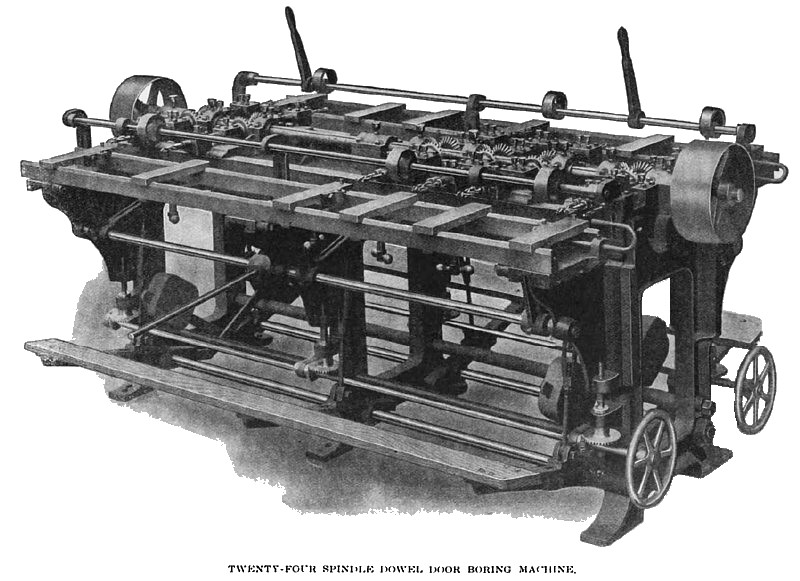

The Yerkes & Finan Wood Working Machine Co., of St. Louis. Mo., has brought out a line of new and greatly improved machines of special interest to door manufacturers, Among these machines are a six-spindle rail boring machine for dowel doors, a double automatic cut-off saw and a twenty-four-spindle dowel door boring machine. The new line represents the very latest, up-to-date features in machinery of its kind.

In this connection we take pleasure in using an engraving illustrative of the twenty-four spindle dowel door boring machine, together with a few words pertaining to its more salient and superior features, speaking from a mechanical standpoint.

The machine is designed for the rapid and economical production of dowel doors and screen doors, and among the claims made for it of especial interest to door manufacturers is that it will do the Work for which it is designed more cheaply than competitive tools.

It will bore twenty-four holes at a. time, twelve on each side (or any less number desired) at the rate of 2,500 doors per day, with operator at each side.

It will bore any number of holes on each side, from one to twelve, as close as 4½ inches apart and up to 74 inches, which is the greatest distance that can be bored on it.

The table is adjustable vertically 2½ inches, which is ample adjustment for any sized doors, and will bore 3½ inches deep or less; depth is regulated by adjustable stops.

Suitable stops, gauges and hold-downs are provided for all adjustments, and when machine is set up (which is very easily and quickly done) any number of stiles may be bored with the positive assurance that they will not vary in any particular.

The table is counterbalanced, making it very easy for the operator to get out the greatest amount of work. (Machine can be equipped with a power feed works, if desired. at extra expense.)

The spindles are made from high grade crucible steel of large diameter, are run in bronze and babbitted bearings 3¼ inches long, driven by bronze and steel gears, and will bore, as stated above, as close as 4½ inches apart, Where a closer distance than that is required, the manufacturers make the bits in clusters of two. three or more, using steel spur gears to get the proper distance as close as 11? inch centers. These clusters are not made adjustable, but can be made to suit the work.

The power for the spindles is delivered to them by two 5 by 12 pulleys, one on each end of the machine. The countershaft is equipped with tight and loose pulleys. 12 by 6. The machine is furnished with one set of ½ inch or 9-16 inch bits, wrenches, etc., and weighs 3.500 pounds.

For further information in regard to it address the Yerkes & Finan Wood Working Machine Company, St. Louis, Mo. |

|

1911 Yerkes & Finan Wood-Working Machine Co., 24 Spindle Dowel Boring Machine

1911 Yerkes & Finan Wood-Working Machine Co., 24 Spindle Dowel Boring Machine

|

|