|

Title: |

1908 Article-Drummond Brothers, Ltd., Metalworking Lathe |

|

Source: |

The Model Engineer and Electrician, 21 May 1908, pg. 503 |

|

Insert Date: |

3/28/2014 8:09:33 PM |

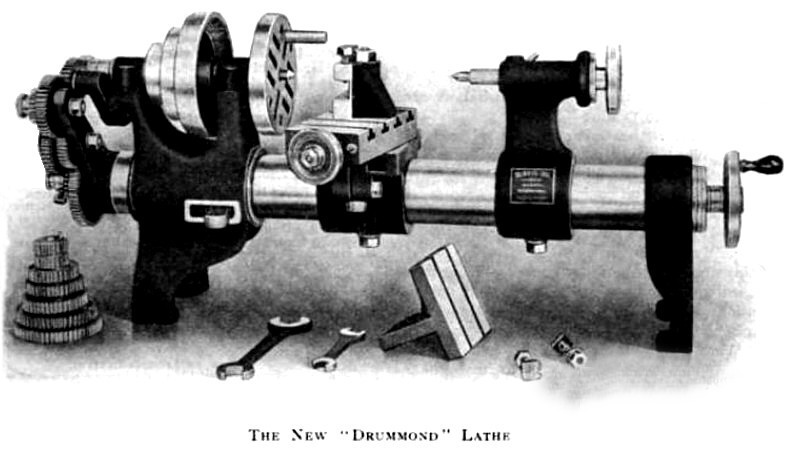

New Drummond Lathe foe Model Makers

When Messrs. Drummond Bros., Ltd., of Ryde's Hill, near Guilford, announced their intention of putting a model maker's £5 screw-cutting lathe on the market, it was confidently expected that something worthy of their high reputation for accurate and well-designed tools would be the result. No one who has seen one of the new lathes will deny that this expectation has been amply fulfilled, for the tool is a production of quite exceptional merit and value. Its most striking feature perhaps is the use of a bed of circular section, with a revolving slide-rest. This possesses a double merit—firstly, in enabling the greatest accuracy to be provided at a minimum of manufacturing cost; and, secondly, in affording the many advantages of tool and work adjustment which the revolving slide-rest and work table permits. The lead-screw, for screw-cutting and self-acting, passes through the centre of the hollow bed, thus being out of the way of chips and dirt. It is put in and out of gear by means of a clutch in the base of the fast headstock. The gear wheels, which are all machine cut, are arranged on studs on a revolving quadrant in the ordinary way, and an extra stud and secondary quadrant are provided to facilitate the cutting of left-hand threads, or to give a reversed self-acting feed. The bed being ground with great precision in an elaborate grinding machine, and the headstock being bored in specially made chucks in the highest class boring lathes, extreme accuracy of alignment of the lathe centres is assured, while the diameter of the bed, and the disposition of the metal in the headstocks, gives great rigidity. The circular slide-rest, with its slotted table, and the slotted angle-plate which fits thereon, make this lathe unusually efficient and adaptable as a milling machine, and the variety of work to which it lends itself is remarkable. The lathe mandrel is of steel, and runs in the best hard gun-metal bearings. It is 1 in. in diameter in the bearings, and is ground dead true after turning. The mandrel nose is ¾-in. Whitworth and is bored to No. 1 Morse standard taper. There is no back-gear to the lathe but the driving pulleys on the mandrel are of large size for a flat strap, and sufficient power is obtainable for all the usual run of model work. A suitable foot driving gear, specially designed for this lathe, or a suitable counter-shaft for power, may be obtained at a moderate extra cost. The length of the lathe over all is 2-ft. 11-ins.; the length between centres, 12 ins.; the height of centres 4 ins.; the diameter of work admitted over saddle is 6 ins.; and the approximate total weight is 145 lbs. We confidently predict a large sale for this splendid tool, both amongst model engineers for whom it has been principally designed, and also amongst, manufacturing firms who have uses for small accurate lathes. A full descriptive booklet may be had on application from the makers at the above address. |

|

1908 Drummond Brothers, Ltd., Metalworking Lathe

1908 Drummond Brothers, Ltd., Metalworking Lathe

|

|