|

Title: |

1900 Article-Smith & Coventry, Boring & Turning Mill |

|

Source: |

English & American Lathes, 1900 pgs.115 & 163 |

|

Insert Date: |

12/18/2012 7:50:06 PM |

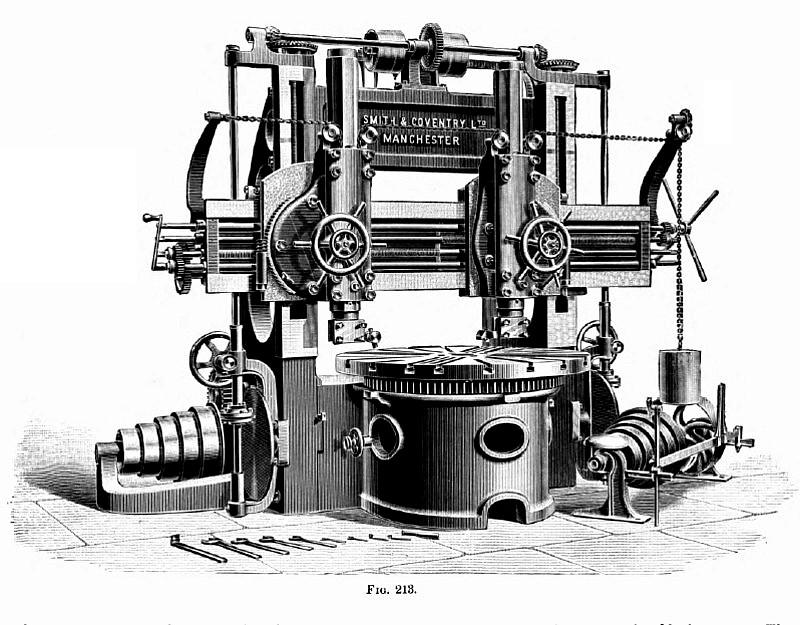

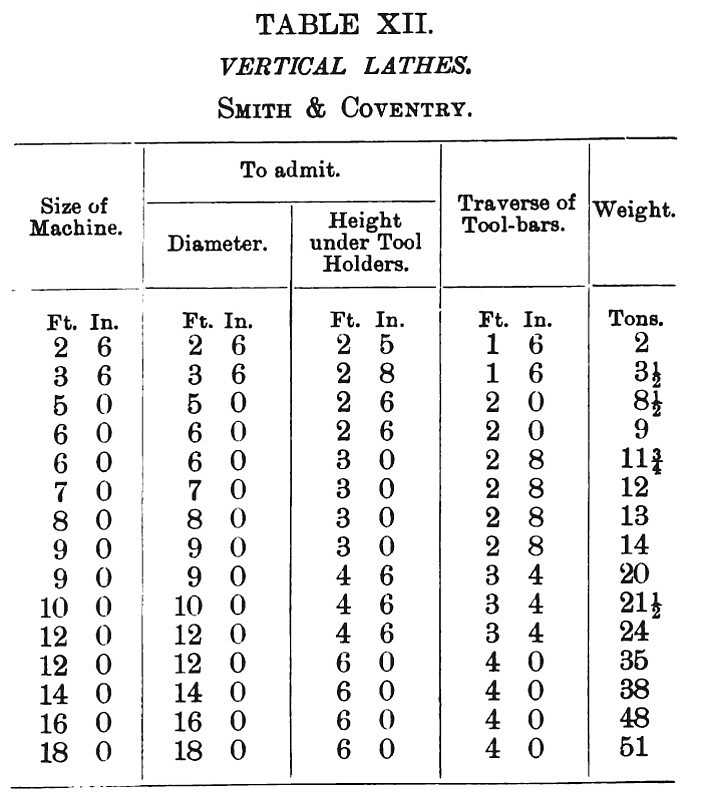

Fig. 213 illustrates a 5-ft. boring and turning mill, by Smith & Coventry, of Salford, Manchester, and Table XII. in Appendix gives particulars of the sizes in which these are made.

The table is driven by powerful spur-gearing. It is attached to a massive vertical spindle, which is carried in the bed and receives all lateral thrust, and is further supported near the periphery by a broad annular bearing with self-oiling arrangements. This outer bearing gives the table a solidity, which cannot be obtained in a face-lathe. All sizes of mills above 6 feet capacity are provided with an arrangement for raising the table off- its outer bearing when it is required to run at an accelerated speed. The speed-cone and gearing is correctly graduated to give the table the proper cutting-speed for all diameters, the position for the belt being indicated under the driving-cone.

The cross-slide is raised and lowered by power on the uprights. It carries two heads, which are in every way independent of one another, and may be controlled from either side of the machine. The uprights are bolted and gibbed to the bed of the machine, and stayed together at the top by a cross-stay of deep section.

The heads are made right and left hand, so that the tool-bars may be brought close together. They have self-acting and hand-traverse by screw in either direction along the cross-slide (the larger machines have a quick hand-traverse by rack and pinion). Each tool-bar is octagonal in section, and is carried on its saddle in a swivel-slide controlled by worm and wheel. The traverses of the tool-bars are independent and automatic in all directions. The tool-bars are counterbalanced so that they travel up or down with equal facility.

The feeds are separate and entirely independent, by friction bowl and disc for each head and tool-bar. By this means the heads may have any variation of feed either in the same direction or opposed to one another on the cross-slide, and the tool-bars may likewise be fed independently of one another, either up or down, or at an angle. |

|

1900 Smith & Coventry, Boring & Turning Mill

1900 Smith & Coventry, Boring & Turning Mill

1900 Smith & Coventry, Table XII

1900 Smith & Coventry, Table XII

|

|