|

Title: |

1890 Article-Egan Co., Graduated-Stroke Mortising Machine |

|

Source: |

Industry Magazine, Oct 1890, pg. 44 |

|

Insert Date: |

12/9/2012 1:11:22 PM |

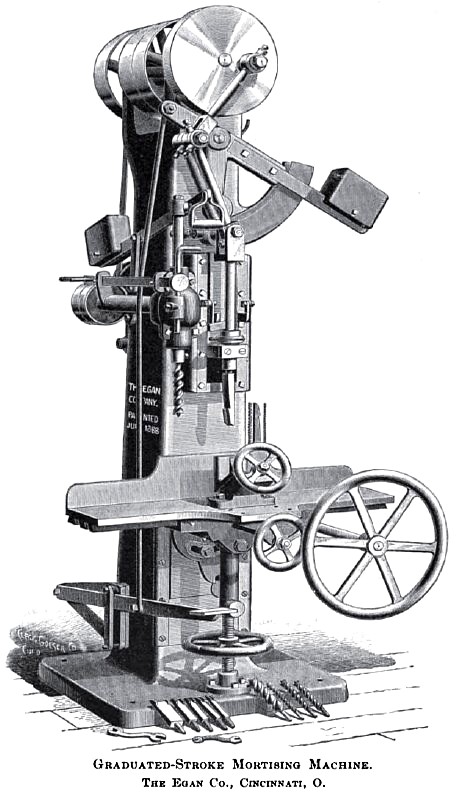

The fine engraving herewith has been sent to us by the Egan Company, of Cincinnati, Ohio, and we propose to make these machines the subject of this month's article on Wood-Working Machinery. The machine shown belongs to a class called "graduated-stroke mortising machines," which were first invented in Cincinnati, Ohio, more than thirty years ago, and so far as we know have never been made anywhere else since. This is a singular circumstance but is true and the claim is made after a tolerably thorough acquaintance with the matter in this and various other countries.

A “graduated” stroke machine and a “variable” stroke machine are very different. Of the latter there have been many invented, of the former, as before said, only two that have come into general use. In a graduated-stroke machine the chisel is set in motion from a still point; its stroke gradually increasing, downward from that still point, and not as in a variable stroke, passing equally above and below the center. In the first case, the stroke of a machine need not be greater than from a half to one inch more than the depth of a mortise, but in the variable machine the stroke must be "twice" the depth of a mortise, plus the clearance. For illustration a graduated-stroke machine will cut a mortise 6 inches deep with a stroke of 7 inches, and a variable stroke one will require a range of 13 inches for the same work.

As a geometrical problem this is by no means plain and has not been well understood in this country and not at all in other countries. This feature of operation was no doubt an accident at the beginning. A Cincinnati mechanic by the name of Guild, of the firm of Hinckle & Guild, contrived a power attachment for a foot-mortising machine, between 1858 and 1860. To give the chisel a reciprocating motion, he placed beneath the floor a pivoted vibrating lever and on this fixed a sliding block to which a link from the chisel slide was attached. This block was moved on the lever by means of a treadle and when brought to the outer end, where the crank connection was attached to the lever, the effect was the same as though the chisel bar was connected direct to the crank, giving a full stroke to the chisel, the lever having no function; but when the block was moved back to the fulcrum of the lever the motion of the chisel bar stopped, but stopped at the "top" of its stroke by reason of the diagonal position of the connecting rod to the chisel bar. This machine would cut mortises nearly as deep as its stroke and when not at work the chisel bar would stop.

This was the beginning of what has proved a great invention in woodworking. The machines were improved; the lever was placed on the top and made an integral part of the machines. Messrs. Lane & Bodley, of Cincinnati, began the manufacture and have made thousands of machines on the Guild principle.

The other graduated movement, embodied in the Egan Company's machine, shown in the illustration, was a later invention made by Mr. G. V. Orton, who is well known to many of our readers, and was long connected with the firm of Messrs. H. P. Gregory & Co., of this City.

The first machine was made about 1865, and while it had the movement required for the chisel bar, it communicated so much jar or shock to the treadle, that workmen declined to use it on hard wood. This is overcome by various expedients, one of which and a very complete one appears in the present machine. The movements of the machine are difficult to explain, it is called a triple connection, or sometimes a knuckle joint movement. When the chisel is at the top of its stroke and still, the two lower links vibrate on the same center at the bottom as well as the top end, but when the back link, the one next the column, has its lower fulcrum moved away from that of the one attached to the chisel bar, then the latter gradually partakes of the crank motion until the two front links form a vertical line through their centers, and the chisel has a stroke equal to that of the crank above.

There are advantages in both the "Guild" and "Orton" methods, the latter is more compact and capable of high speed. As remarked in the beginning, it is wonderful that an invention of such importance should not have found its way into wider use in thirty years, but it must be remembered that not one in ten who use the machines understand the principle involved in their movements. The Egan Company's machines have, in respect to these movements, come down to the present day on the principle of "evolution," explained in another article in the present number. The machine illustrated is an ingenious adaptation of the triple link movement, is a well designed, and what is especially essential in a mortising machine, strong and substantial. |

|

1890 Egan Co., Graduated-Stroke Mortising Machine

1890 Egan Co., Graduated-Stroke Mortising Machine

|

|