|

Title: |

1895 Artricle-Detrick & Harvey Machine Co., Smith Band Saw Setting & Filing Machine |

|

Source: |

Chicago Journal of Commerce, 25 Apr 1895, pg. 11 |

|

Insert Date: |

11/6/2012 8:40:59 PM |

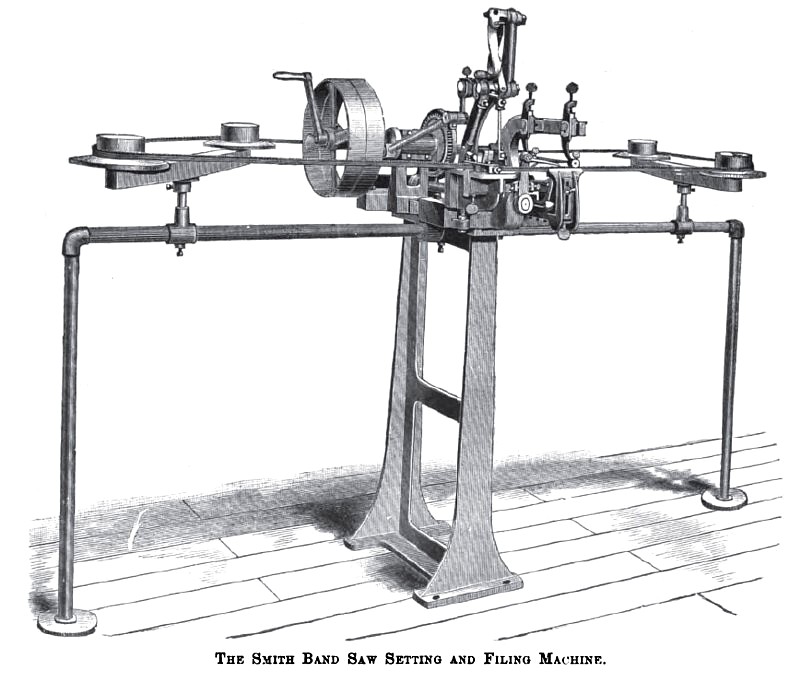

THE SMITH BAND SAW SETTING AND FILING MACHINE.

The Detrick & Harvey Machine Company, Baltimore, Md., recently placed on the market the Smith band saw setting and filing machine here shown. The machine is mounted on a cast iron pedestal, and occupies a floor space about 16 inches wide by 20 inches deep. It is designed to imitate, as nearly as possible, the movements made in filing and setting band saws by hand, but at the same time it has been the object of the designers to overcome the irregularity of hand filing, seen in the high and low teeth in a blade after being hand filed. Any ordinary three cornered file from 3 to 6 inches long may be need. The main driving shaft has connected to it last and loose pulleys, with a suitable lever for easily disengaging the belt. On the end of the shaft is a wheel, to one spoke of which en arm is pivoted to give s reciprocating movement to a sliding table. The file is carried within adjustable jaws by an overhanging arm on the sliding table, and the tooth of s sew is filed during the forward movement of this arm only, any desired rake being given by a simple adjustment of the file. At the end of the stroke the file is lifted clear of the saw tooth by the tilting upward of the sliding table, caused by a cam located on the wheel at the end of the shaft elevating the forward end until the return stroke is completed, when it again drops into position for filing. Another cam on this wheel gives a rotary reciprocating motion to a shaft, which in turn, operated by a pawl, pushes the saw forward one tooth. This tooth feed may be instantaneously adjusted to suit any pitch of saw. The saw tooth when fed up is filed, and each succeeding tooth is filed in the same manner, all being filed exactly to one pitch and

height. The vise in which the saw is held is adjustable to the thickness and depth of the blade, and is so constructed as to hold the saw firmly in position while being filed, and yet allow for the passage of any inequalities in the thickness of the blade. On the sides of the machine are pipe tees bearing reels for holding the saw in position while being filed.

The setting of a saw is accomplished by means of two hammers hung from an overhead shaft and operated by means of strong springs. On of the main shaft is a small gear operating s similar gear having an arm pivoted to it and thus giving an intermittent movement to two pawls which alternately lift up the hammers at the proper time and release them quickly, the springs on such release causing the hammer to deliver a sharp blow to the saw. The spring may be adjusted to regulate the force of the blow, according to the thickness of the saw and the amount of set required. The setting being effected by the hammers on anvils having the desired angle, it is claimed that the teeth retain their position after being struck, and do not spring back, The angle blocks and hammers may also be adjusted to the varying conditions of saws. Both netting and filing are accomplished on the machine at one time, but either operation may be performed separately. An attachment for filing circular saws up to 30 inches in diameter is also furnished when required. The machine may he operated at different speeds, but is usually arranged to run at about sixty strokes per minute at which speed it will set and file accurately an ordinary 21 foot band saw in about twenty minutes. |

|

1895 Detrick & Harvey Machine Co., Smith Band Saw Setting & Filing Machine

1895 Detrick & Harvey Machine Co., Smith Band Saw Setting & Filing Machine

|

|