|

Title: |

1907 Article-William E. Hill & Co., Steam Drag Saw |

|

Source: |

The National Coopers' Journal Mar 1907, pg 2 |

|

Insert Date: |

1/1/2012 10:37:26 PM |

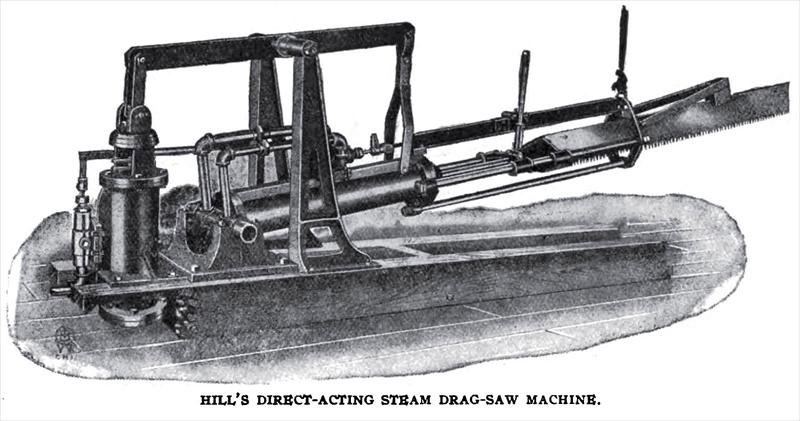

Direct-Acting Steam Drag-Saw Machine.

In describing the direct-acting steam drag-saw machine its manufacturers, Wm. E. Hill & Co., Kalamazoo, Mich. say: The construction of our New Patent Direct-Acting Steam Drag-Saw Machine, as illustrated above, is radically different from that of any other drag saw, and is by far the most simple and compact. The machine occupies very little space and is really a self-contained steam engine with the saw fastened to the piston rod. It has few parts, consisting mainly of base, cylinder, valve and connections, crosshead which is attached directly to piston and to which saw is secured, suitable guides for cross-heads, saw guide and a device for raising and lowering saw and feeding it while it is in the cut.

The cylinder is provided with a positive steam cushion at each end of stroke so that, even at maximum speed, it is impossible to knock out cylinder heads. This perfect cushion also serves to obviate the jarring of foundation and end play so common in other types of drag saws. The machine can be placed in the upper story of a mill or factory without inconvenience.

The valve is radically different from anything used heretofore, and is so simple in construction that it cannot get out of order. It is operated from cross-head and allows a very high piston speed.

The main part of the machine hinges on trunnions, which work in a heavy base. We build the machine with two styles of base; the one known as the stationary base bolts rigidly to the floor and does not allow any lateral movement. The other, the movable base, is worked laterally in a sub-base, which is bolted firmly to floor, by turning the hand wheel shown in cut. This wheel turns a pinion, which in turn engages a rack on sub-base, moving the machine very easily. This is often a very desirable feature, as sometimes it is difficult to stop a log at the exact spot wanted, and with this device it is not necessary, as by a single turn of the handwheel the saw can be brought to the exact spot where the cut should be made. The distance the saw can be moved laterally is 30 inches.

The mechanism for counterbalancing the machine and regulating the feed of the saw is very simple. The machine is partially balanced by a weight which is fastened to a rope passing over the sheaves and attaching to yoke of drag saw. By taking out or adding to the weight in the box, the feed can be increased or decreased. In addition to this the operator is given control of the feed and provided with a simple hoisting device in the rig shown in left of cut.

This consists of a drum to which rope running to saw is fastened, ratchet and dog for holding saw up, and large rope wheel around which operator's rope is passed several times, giving him an increased leverage, so that feed can be regulated very easily, by the pull he puts on rope, and the saw easily raised from cut. The speed of the saw can be regulated by the hand lever shown in cut.

The Steam Hoisting Cylinder shown in cut is a very valuable adjunct to the Steam Drag Saw Machine. It does away with the operator having to lift the saw, as with the common hoisting rig. This is very convenient where drag saw is located outside of building, where there is no superstructure to carry the hand or power-hoisting rig.

The cylinder is so arranged that it is under perfect control of operator, and saw can be raised or lowered with ease and rapidity, and at the same time be under perfect control. For further information or particulars, address Wm. E. Hill & Co., Kalamazoo, Mich. |

|

1907 William E. Hill & Co., Steam Drag Saw

1907 William E. Hill & Co., Steam Drag Saw

|

|