|

Title: |

1906 Article-E. & B. Holmes Machinery Co., Barrel Hoop Nailer |

|

Source: |

The National Coopers' Journal May 1906, pg 5 |

|

Insert Date: |

12/27/2011 8:02:24 PM |

|

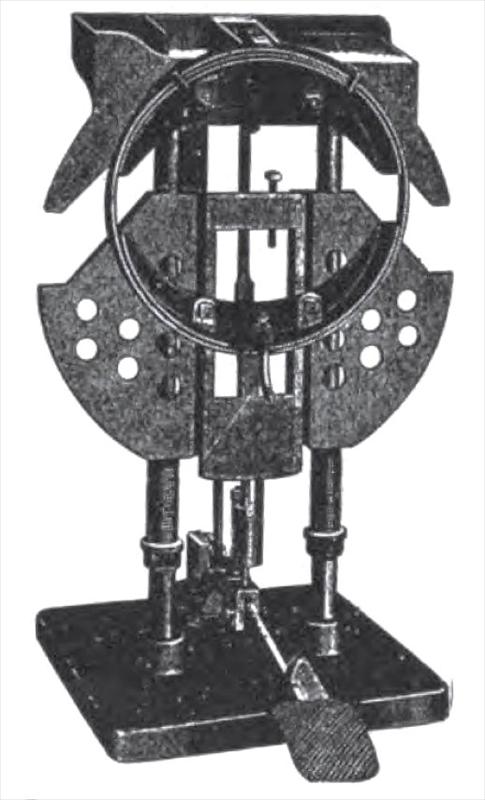

The Holmes Hoop Nailer — To make slack barrels by machinery, it is necessary to have the hoops nailed to exact sizes. The cut illustrates the latest improved hoop nailing machine. The operator places the hoop on the form, steps on the lever, pressing downward until it is caught by the dog. The upper finger on the machine holds the hoop in place while the operator nails it; then the operator steps on the dog, which releases the lever, allowing the lower form to rise so that the operator may remove the hoop, leaving the machine ready for the next one. The upper casting is fitted with three compartments, one for holding the staples, one for the nails, and a place to lay the hammer, which does away with the necessity of attaching a wooden table to the machine and makes it much more convenient for the operator. It is a very simple and strongly built machine and can be used for any size hoop. A small lad can nail from 1,500 to 2,000 hoops per day. Machine is furnished complete for nailing one size hoop; extra formers for different sizes can be furnished if desired. In ordering, specify the size hoop to be nailed. Weight of machine, 250 lbs.; floor space required, 2 feet by 2 feet; contains 12 cubic feet. |

|

1906 E. & B. Holmes Machinery Co., Barrel Hoop Nailer

1906 E. & B. Holmes Machinery Co., Barrel Hoop Nailer

|

|