|

Title: |

1895 Article-Egan Co., Heavy Wood Planer |

|

Source: |

Modern Mechanism 1895 pgs 632-633 |

|

Insert Date: |

12/4/2011 8:57:43 PM |

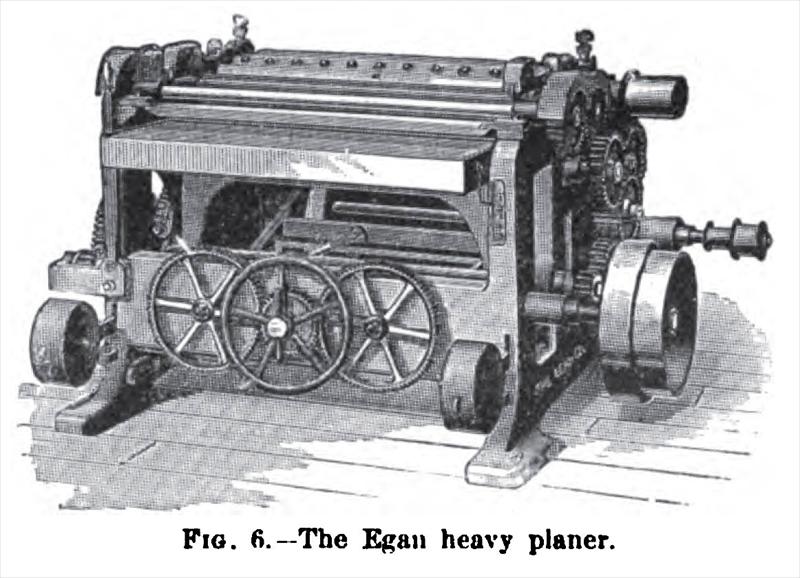

Heavy Planer — It is for some reasons best for planers working on doors, sash, and other articles having the grain of the wood at different angles, that the planer head be at an angle of 45°, giving a smooth surface regardless of knots or cross grained places in the material being worked.

The heavy planer and smoother shown in Fig. 6, and made by the Egan Co., is made by reason of the desire of sash and door makers, and others producing similar classes of work, to put their work together in sections, and plane the latter after they are put together. This of course calls for a wide planer, in order to feed the stock diagonally, to preserve the edges when planing the cross rails. There are heavily braced double or cored sides to the frame. The table, which is dovetailed in the frame, raises and lowers in inclines by two screws and a centre hand wheel, and can be locked at the desired height. The feed consists of four large feed rolls, all driven by heavy gearing, the upper front one, which is fluted, being geared on both ends, giving it a parallel lift, and thus allowing two strips of any kind of stock to be fed through the machine. All four feed rolls are weighted. The feed of the machine is taken from the cylinder, so that if the speed of the latter increases or diminishes, the feed will vary in the same proportion. The pressure bars each side of the cylinder adjust to the circle of the head, to prevent tearing out of wavy grained or knotty stock, and chipping of the ends. By feeding the stock in diagonally instead of having a diagonal planer, straight belts may be run to the cylinder, and short stuff may be planed. Such a machine is specially adapted for planing framed stock where straight and cross-grained wood are built up together. |

|

1895 Egan Co., Heavy Wood Planer

1895 Egan Co., Heavy Wood Planer

|

|