|

Title: |

1896 Article-Ransomes, Sims & Jefferies, Agricultural Steam Locomotive |

|

Source: |

Cassier's Magazine Jun 1896 pgs 147-148 |

|

Insert Date: |

7/21/2011 10:21:37 AM |

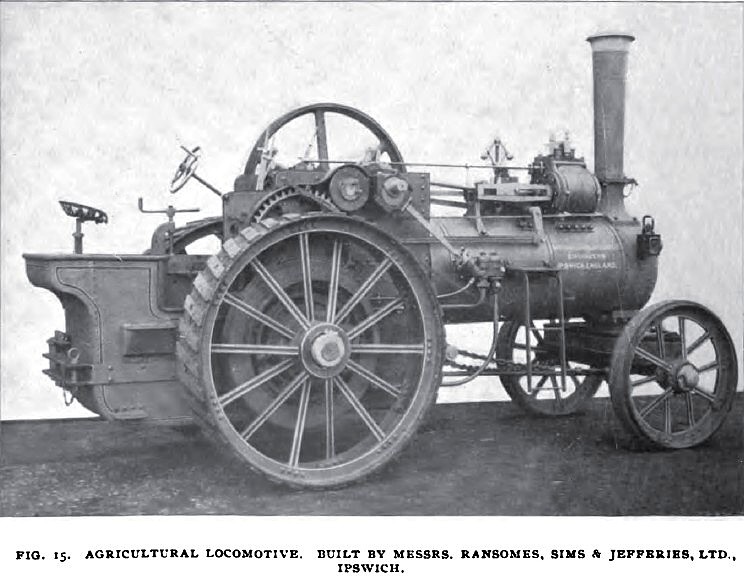

Fig. 15 shows one of Messrs. Ransomes, Sims & Jefferies' improved agricultural locomotives of the single-cylinder type. A large number of these engines have been manufactured and are doing excellent service on farms.

A few years ago there was every indication that the compound traction engine would become very popular, but this result has hardly been realized. The compound engine has been adopted in many cases, but those makers who have specially boomed their compound engines still continue to make a good number of single-cylinder engines. Some firms say, "We can supply traction engines made on the compound principle, but we recommend the single cylinder engines, as, with the latest improvements, they work very economically and have only half the number of parts." There are other manufacturers who are prepared to supply compound engines, but who are rarely asked for them. The greater proportion of their orders are for single-cylinder engines. For continuous hauling work, however, the compound engine must be recommended. If this type of engine is worked at the full boiler pressure of 150 lbs. per square inch, a saving of thirty per cent, in fuel and water will be secured. The noise produced by the exhaust steam also is reduced, which is an advantage. The shocks upon the crank-pins, gearing and other working parts are less severe. An auxiliary valve is provided, which allows high pressure steam to enter both steam chests, and both the cylinders exhaust into a common exit pipe (the compound principle being suspended for the moment), enabling the engine to start readily with a heavy load behind. As soon as the engine is under way the valve is closed. A relief valve is fixed on the low-pressure steam chest.

For threshing purposes the compound engine cannot be so fully recommended on account of the reduced steam pressure employed for threshing, — from 80 to 100 lbs. pressure being quite sufficient. Not only so, but also for this work the attendants are often very unskillful, so that it is an advantage to have the simplest possible engine. The first cost is also a consideration with the threshing fraternity. While on the subject of cylinders we may refer to the proposal to bolt the cylinder on a wrought steel fixing or girder, instead of bolting the casting direct to the boiler barrel as heretofore. The base of the cylinder and the seating are planed, so that having a flat surface, the joint is more easily made and retained. None of the bolts pass into the steam space. For export engines this method of construction possesses important advantages. Beyond this there does not seem to be any great value in the plan.

Now that steam pressures are steadily creeping up, some makers have experienced trouble in keeping the joint tight under the cylinder, around the steam inlet, but if the joint is properly fitted there will be no fear of leakage. |

|

1896 Ransomes, Sims & Jefferies, Agricultural Steam Locomotive

1896 Ransomes, Sims & Jefferies, Agricultural Steam Locomotive

|

|