|

Title: |

1895 Article-E. P. Allis & Co., Reverising Rolling-Mill Steam Engine |

|

Source: |

Modern Mechanism 1895 pg 318-319 |

|

Insert Date: |

6/11/2011 8:33:20 PM |

|

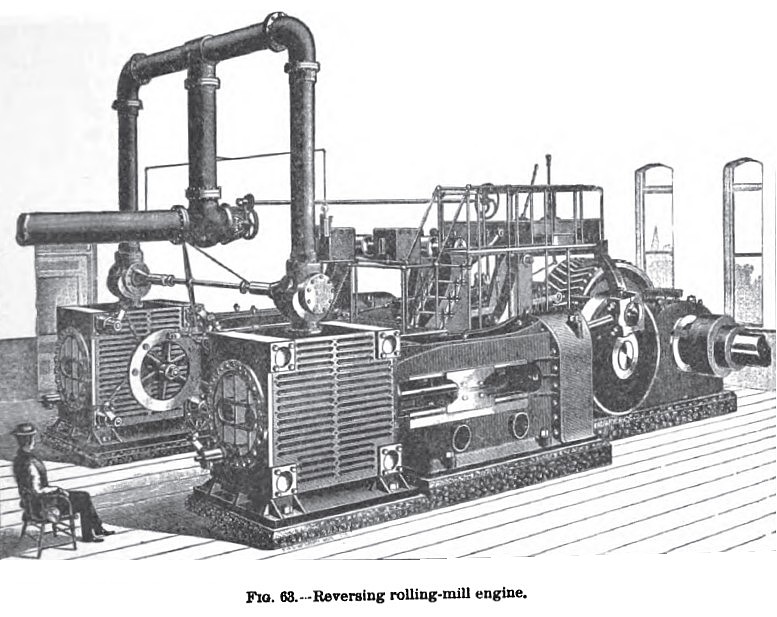

The Allis Rolling-Mill Reversing-Engine (Fig. 63) shows a pair of rolling-mill engines built by the E. P. Allis Co. for Carnegie, Phipps & Co.'s Armor Mill in Pittsburg, Pa. The engines are driving a two-roll high train, and are reversed at every pass of the plate in the rolls. The steam cylinders are 40-in. diameter by 54-in. stroke, with Reynolds' Corliss valve-gear without the drop cut-off mechanism; the speed of the engines is controlled by the operator, and is varied in every-day practice from 5 revolutions to 120 revolutions per min. The reversing gear is handled by a counterbalanced reversing mechanism, operated by steam, which is controlled by a lever on the engineer's platform; from this position he has an unobstructed view of all parts of the engine and roll-train. The journals for the roll-shaft and engine crankshaft are formed in the same pillow-block, each one having proper means of taking up wear and adjustment. Power from the engine crank-shaft is transmitted to the roll-shaft by means of a pair of shrouded helical tooth steel gears. |

|

1895 E. P. Allis & Co., Reverising Rolling-Mill Steam Engine

1895 E. P. Allis & Co., Reverising Rolling-Mill Steam Engine

|

|