|

Title: |

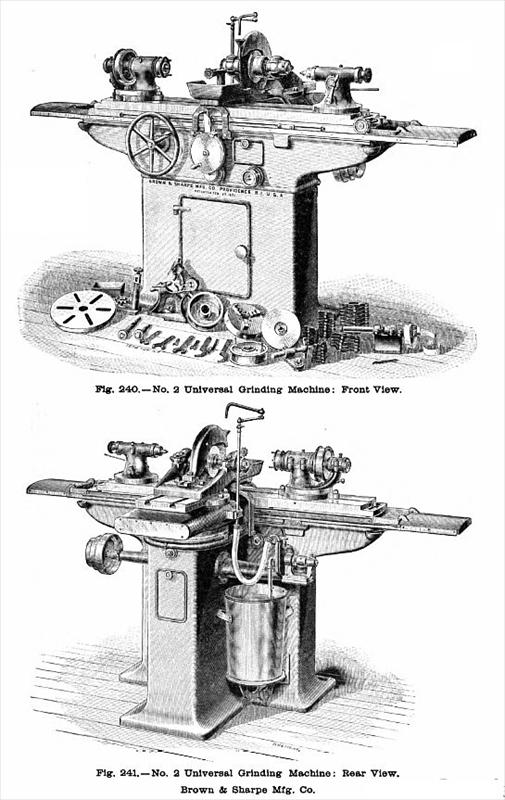

1895-1896 Image-Brown & Sharpe Mfg. Co., #2 Universal Grinding Machine |

|

Source: |

Illustrations and Details of American Machine Tools-MIT 1896 pg 128 & Modern Mechanism 1895 pgs 407-408 |

|

Insert Date: |

6/24/2011 10:55:44 AM |

|

Brown & Sharpe's Universal Grinding Machine—This machine, shown in Fig. 240, is suitable for both straight and taper, internal and external grinding, and is used in the manufacture of spindles and boxes, either hard or soft cutters, either straight or angular reamers, arbors, jewelers' rolls, and standard external and internal gauges. The sliding-table carries a swivel-table, which turns upon a center-pin. This provides for grinding tapers without throwing the head and foot stock spindles out of line. In order that the swivel-table may be set accurately, it is provided with an adjusting screw. A scale shows the taper both in degrees and in inches per foot. The table may be fed and reversed automatically or by hand. The cross-feed is operated by hand. The head-stock is attached to a base-plate bolted to the swivel-table, and turns upon a center-pin. Its circumference at the lower edge is graduated to degrees. The foot-stock spindle is adjusted by a lever, and there is a spring to accommodate the expansion of the work. The machine will swing work between centers 12 in. diameter and 30 in. long. The swivel-table can be moved to either side of its central position to grind tapers from 0 to 2 in. per ft. For grinding work on the face-plate or chuck, the head-stock can be set at any angle within the whole circumference. Two tapers can be ground, either internal or external, without changing any of the settings. The work can be ground upon fixed centers, being driven by a pulley which revolves upon one of them, or the head-stock spindle can be revolved while the work is held in a chuck. Wheels are used from ± in. to 12 in. diameter. |

|

1896 Brown & Sharpe Mfg. Co., #2 Universal Grinding Machine

1896 Brown & Sharpe Mfg. Co., #2 Universal Grinding Machine

|

|