|

Title: |

1910 Article-Springfield Mfg. Co., Planer Type Grinder |

|

Source: |

Railway Master Mechanic Dec 1910 pg 549 |

|

Insert Date: |

3/15/2011 1:23:00 PM |

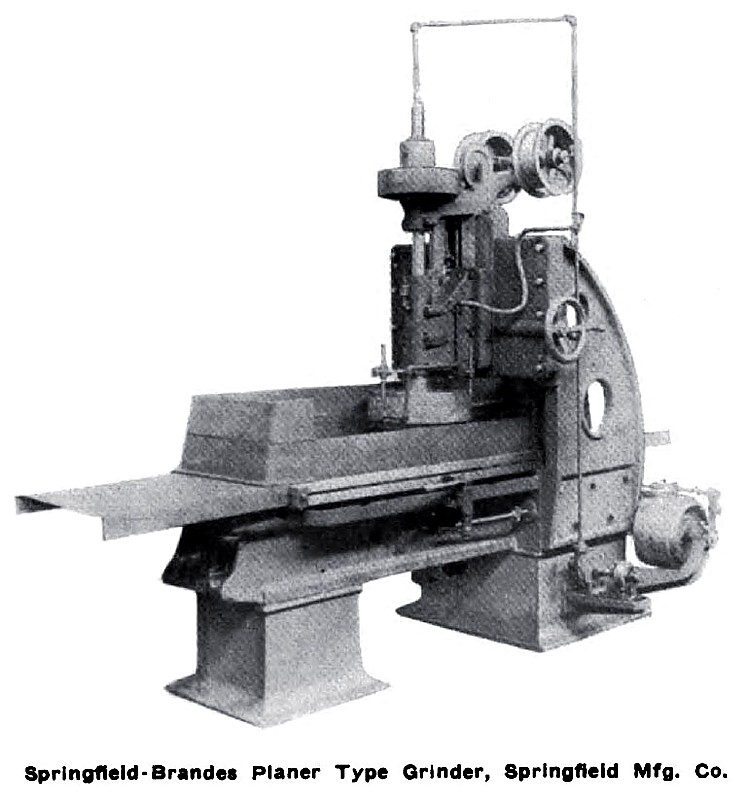

A redesigned planer type of grinder manufactured by the Springfield Mfg. Co., Bridgeport, Conn., is shown in one of the accompanying illustrations. The machine as now built is a very heavy and substantial tool. It has a normal capacity to grind 12 ins. wide, 12 ins. high and 4 ft. long, but can be built for longer work if required.

The wheel head and spindle are of particularly heavy design, the spindle being of large diameter and mounted in exceptionally long bearings, also provided with a ball thrust on the under side, and is equipped with a ball bearing spring take-up on the upper part of the bearing to prevent back lash when the wheel is running off the work. The driving pulley is mounted upon an independent bearing relieving the spindle of all strain of the belt. The wheel is 16 ins. in diameter, mounted in a chuck which permits of easily changing the wheels and is also well protected by guards to insure against accidents in case of damage to the wheel. The guard around the table is made in sections on the front side, so as to permit of being easily removed, the photograph showing the machine with the upper section left off.

The table drive of this machine is of the general planer construction except that in this case the power is transmitted through a worm and worm gear on the rear of the machine, direct to a large and substantial screw which runs in a long nut to insure long life and giving an absolutely smooth action to the table.

The machine as shown is arranged with a hand feed for feeding the wheel to the work and equipped with a micrometer dial back of the hand wheel to facilitate the setting, and getting sizes; and while this machine as shown is arranged for hand feed only, it will also be made with a power feed when desired.

The machine is equipped with a pump to supply lubricant to the wheel, which can be applied either through the spindle, or from the outside, and when applied through the spindle the water is forced against a deflector on the under side of the spindle, so as to force the water to the periphery of the wheel, which is a very essential feature in grinding narrow or interrupted surfaces.

One of the illustrations shows some of the work turned out by this grinder, with dimensions. It is stated that the pieces were all ground from the rough with a removal of stock of from 1/32 to 1/8 in. |

|

1910 Springfield Mfg. Co., Planer Type Grinder

1910 Springfield Mfg. Co., Planer Type Grinder

|

|