Image

|

Title: |

1886 Article-A. W. Stevens & Son, Steam Traction Engine |

|

Source: |

American Mail & Export Journal Aug 1886 pg 32 |

|

Insert Date: |

2/23/2012 6:59:48 PM |

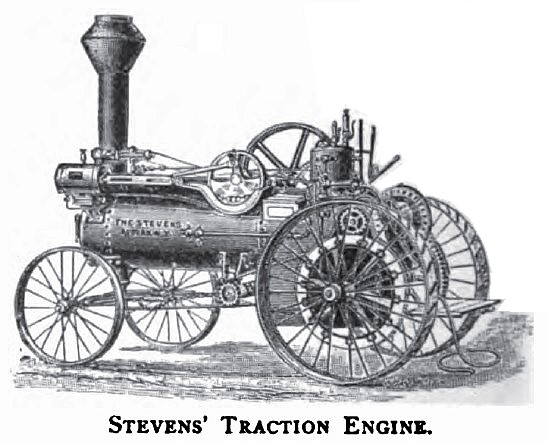

A portable or farm engine has become one of the recognized necessities of a good agricultural country, where farming is carried on with any degree of precision, and the production of engines of this class has become a specialty with a number of manufacturers. Of the many farm engines offered, that made by A. W. Stevens & Son and illustrated in the accompanying engraving is believed to present features, which will impress persons needing such machines. The frame of this engine is made in the form of a half cylinder, which is the strongest form in which iron can be put to secure strength and rigidity. Cast to the frame is the cylinder with the inner end solid. The guides or ways, steam-chest and both main bearings or pillow blocks are all cast together, forming a continuous engine and frame in one piece. In securing the frame to the boiler only thirteen cap-bolts are used. Another feature gained by the construction of the frame in a trough-shape is its adaptation to catch all the oil and drippings which would otherwise drop on the boiler. At the lower end of the frame is a drip-hole, from which all oil and accumulations are carried to the ground clear of the boiler. The pillow-blocks or bearings for the crank-shaft are each eight inches in length, filled or lined with the best quality of anti-friction metal. The guides or ways are each two inches in width and are of the horizontal or locomotive pattern, the lower half being cast In the main frame, and the upper half secured to the frame by machine-screws, underneath which is put metal packing. As the wear comes upon the upper half it is easily and readily taken up. The governor is horizontal and its action is direct and instantaneous, so that a uniform speed is maintained under the most varying loads and pressure of steam.

The governor is driven direct from a pulley on the crank-shaft with a flat belt. The connecting-rod is of cast steel and the cross-head is made in one piece ; the piston-rod is also steel. The boiler is made of the best charcoal hammered iron. The fire-box is made from the best open-hearth fire-box steel.

The engine illustrated is a 12 horse-power traction, of great strength, simplicity, efficiency and durability. Its driving or road wheels are sixty inches in diameter, with ten-inch face. The rims are heavy cast iron and the spokes wrought iron, neither rivets, bolts nor screws entering into the construction of the wheels. The axle of the driving wheels is steel 2^ inches square. It passes in front of the fire-box, under the fire-door and is securely held in position by two heavy corner brackets. The countershaft, to which the road-wheel pinions are keyed, is also steel and is supported by these corner brackets, making a firm and reliable bearing, compact in form. The driving device is a straight train of spur gears. The gears all have broad faces and strong teeth. All necessary gearing is well shielded and protected

from sand and grit and there is no liability of injury to the person running the engine. The steering device is placed on the left side of the engine, in handy position for the engineer. Springs are placed under only the front end of the engine. Metallic springs are placed in each steering chain, so that in case one of the forward wheels strikes an obstruction the strain upon the chain, gears and steering-reel is instantly relieved and after passing the obstruction the wheels immediately resume their proper position, thereby keeping the engine in the direction it should travel. A steel coil-spring is placed in the draw-bar frame, inside of which is placed the draw-rod, so arranged that it assists greatly in starting the load, by allowing the engine to make a few revolutions before the full elasticity of the spring is taken up. An efficient brake, operated by the foot, is instantaneous in action.

The speed of the engine is 200 revolutions per minute. The band-wheel is forty-four inches in diameter, with eight-inch face. The "Hancock" inspirator is used in connection with the boiler. The front and rear throttle levers, reverse lever, steering-wheel, rod for opening and closing cylinder pet cocks, water-gauge cocks, inspirator, ash-pan door and whistle are all located in immediate range and within easy reach of the engineer. |

|

1886 A. W. Stevens & Son, Steam Traction Engine

1886 A. W. Stevens & Son, Steam Traction Engine

|

|

|

|