|

Title: |

1876 Image-Corliss Steam Engine Works, Centennial Corliss Engine |

|

Source: |

The Engineer's Handy Book 1884 pg 24 & The Steam User 1890 pg ii |

|

Insert Date: |

4/2/2011 10:32:30 AM |

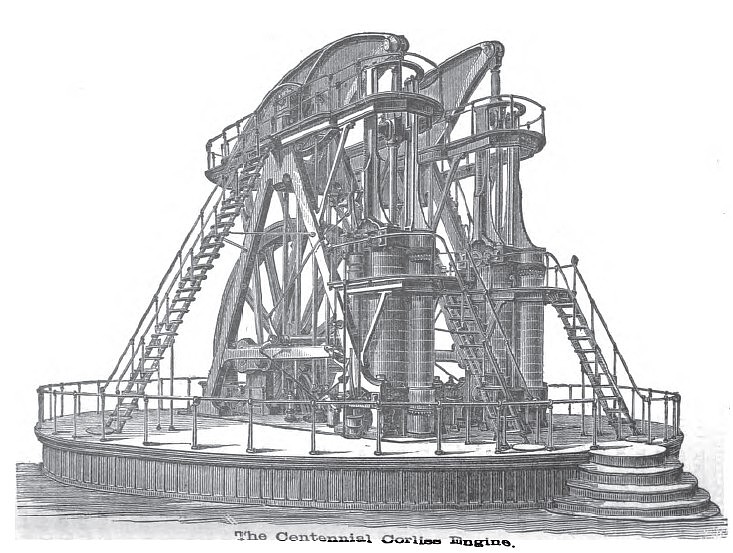

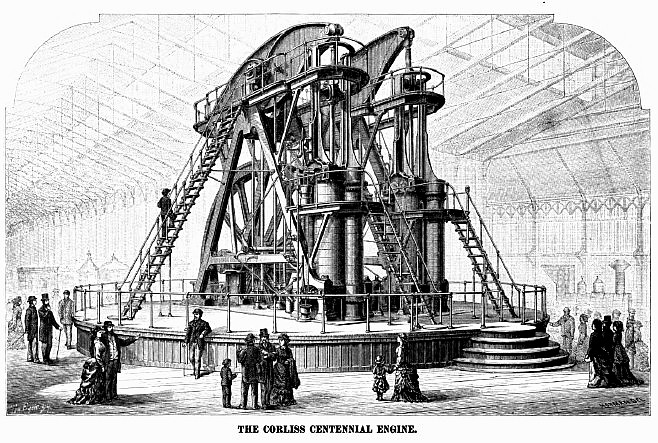

The Centennial Corliss Engines were beam-engines of the Corliss type, with all the latest improvements, and nominally of 700 horse-power each, or 1400 horse-power together. The cylinders were 40 inches in diameter, with 10 feet stroke. They were provided with air-pumps and condensers, consequently they could be worked either condensing or non-condensing, and were intended to work with from 25 to 80 lbs. of steam pressure, according to the requirements of the exhibition. The gear fly-wheel was 30 feet in diameter, 2 foot face, and weighed 56 tons; it was undoubtedly the largest gear-wheel ever made. The pinion that was driven by this large fly-wheel was a solid casting 10 feet in diameter, weighing 17,000 Ibs., and was the largest ever made. The main frame was A shaped, having the journals for the beamcentres on the top, and the legs bolted to the bottom of the cylinder on one side, and to the main crank-shaft journals on the other.

The walking-beams were of the web-beam pattern, and made of cast-iron, and, in consequence of their peculiar shape, detracted very much from the general appearance of the engine. They were 9 feet wide at the centre, and 27 feet long, each weighing 22,000 lbs. The cross-head guides extended from the upper cylinder-heads to the top gallery, and were provided with screws by which they, as well as the cylinder-heads, might be lifted to admit of access to the pistons. The piston-rods, which were made of steel, were 6¼ inches in diameter. The cranks were highly finished, and weighed 10,000 Ibs. each. The connecting-rods were 24 feet long. The steam-valves received their motion from a wrist-plate and a system of levers similar to those employed in. the ordinary Corliss engine, and the releasing gear for them was entirely original, and very ingenious, though the exhaust-valves ended their vibrations by an abrupt kick or jerk.

The height of the engines, from the floor to the top of the walking-beams, was 39 feet, and their weight, with all their adjuncts and attachments, was over 700 tons. The engines were supplied with steam by 20 upright Corliss boilers, of 70 horse-power each. The main steam-pipe was 18 inches in diameter and 320 feet long. The engines rested on a platform 55 feet in diameter, and 3½ feet above the floor of the building. The top of the frame was surrounded by a circular gallery, which afforded access to the beams and all the upper works; this gallery was reached by a semi-circular stairway on each side. These engines were objects of general interest and curiosity, and served to illustrate the wonderful development of the steam-engine in this country, and the amount of inventive genius that must have been devoted to its improvement.

After the close of the Centennial they were taken down and removed to the builder's establishment, Providence, R. I., where they remained until recently, when they were sold to the Pullman Palace Car Co. for the purpose of furnishing the motivepower for their works, near Chicago, and also the power for the Allen Paper Car-Wheel Works adjoining.The engraving on the opposite page is a good illustration of the famous Corliss Engine which was used at the Centennial in Philadelphia in 187:. It was designed by the late Geo. H. Corliss, and after the close of the Exposition was removed to Pullman, 111., where it now furnishes the power for the great car shops.

On the following page is shown an engraving of one of the latest installed steam plants, of the triple expansion tjpe, for driving large powers, it having been but recently built and erected by the Corliss Steam Engine Co., of Providence. The engines are arranged as a pair, with cranks at right angles connected to a common main shaft and pulley fly-wheel; aside from this, each engine is complete in itself, having its own steam stop valve, connected air-pump and jet-condenser, with the necessary pipe connections.

The cylinders are arranged "tandem," the dimensions being as follows: high pressure, 16" diameter, intermediate 28" diameter, low pressure, 42" diameter, with stroke of 60".

The pulley fly-wheel is 28 feet in diameter by 114" width of face, and is crowned for four belts, two of 32" each, one of 26", and one of 16" in width. This pulley weighed finished 97,728 pounds.

The cylinders are steam jacketed, neatly cased with sheet steel instead of the ordinary black walnut lagging, and each one is provided with the company's patent safety relief spring attachment for allowing the escape of entrained water.

This relief, which has proved itself invaluable in a number of instances, is in the form of a long flat steel spring, the ends of which press upon valves located in the back bonnets of the exhaust ports.

These engines are now in regular service at the new mill of the Fall River Iron Works Co., Fall River. Mass., and are rated at 1,300 horse-power, at the contract speed of 65 revolutions per minute, with initial steam pressure of 150 pounds.

In addition to the manufacture of stationary steam engines, this company has constructed, from the designs of the late George H. Corliss, several pumping engines for public water supply, notable among which may be mentioned the "Pawtucket" three million engine, which enjoys the international reputation of being one of the most economical pumping engines in the world in the use of fuel.

Last year this company built and erected, for the same city, a "six million pump, which is an exact counterpart of the original in all of the essential features, and is shown in the accompanying illustration. The cylinders are 20" and 40" diameter by 40" stroke, arranged as a cross-compound; and the engine works with comparative ease while making the required 50 revolutions per minute, pumping against a dynamic head of 270 feet.

The figures on the next page have been taken from the printed official reports of the performance of the smaller engine, and are interesting from the fact that they show a large increase rather than the usual diminution in the fuel economy after an interval of ten years of continuous and excessive service. |

|

1876 Corliss Steam Engine Works, Centennial Corliss Engine

1876 Corliss Steam Engine Works, Centennial Corliss Engine

1876 Corliss Steam Engine Works, Centennial Corliss Engine

1876 Corliss Steam Engine Works, Centennial Corliss Engine

|

|