|

Title: |

1884 Image-Putnam Machine Co., Steam Engine |

|

Source: |

The Engineer's Handy Book 1884 pg 139 |

|

Insert Date: |

2/26/2011 12:10:09 PM |

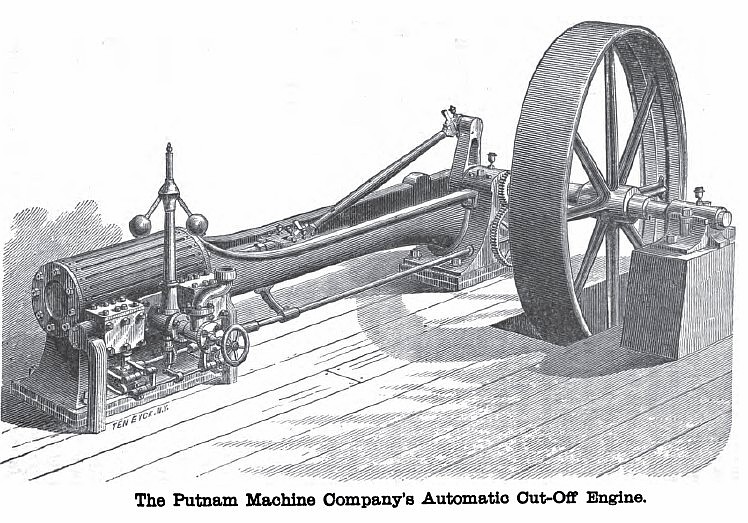

The Putnam Machine Company's Automatic Cut-Off Engine.

The opposite cut represents the Putnam Machine Company's high-pressure variable cut-off engine, the frame or bed-plate of which is designed with reference to strength and rigidity, and also to answer either for right or left hand pillow-block bearings. The almost universal reciprocating valve-motion derived from an eccentric is dispensed with, and a rotary motion derived from a gear on the crank-shaft substituted. By means of mitre-gears the motion is communicated to a shaft running parallel with the axis of the cylinder beneath the valves, and carrying cams for lifting the latter. The steam-chests, one at either end of the cylinder, contain each a steam and an exhaust valve of the balance or double-poppet form, having flat faces and seats, and are capable of being removed entire from the steam-chests by simply removing a bonnet or cover on the top of the latter. The valve-stems pass through the necessary stuffing-boxes in the bottom of the steam-chests. The shape and adjustment of the cams for working the valves give them the proper lift, lap, lead, etc. The opening and closing of the valves are very quick, the duration of opening being an interval of rest between the upward and downward motions.

The governor, which is of the ordinary centrifugal form, is driven by bevel-gears from the cam-shaft, thus receiving a positive motion. Below the cam-shaft is a rack-shaft having three arms, the centre one of which is attached to the lifting-rod or spindle of the governor, from which the rack-shaft receives a slight oscillating motion, while those at the ends, which are at right angles with the centre arm, connect with the lifting toes of the steam valve. The shape of the lower faces of the lifting toes which rest upon the cams is such, that when moved inward towards the cylinder, by the motion of the governor transmitted through the rack-shaft, a curved upward offset is reached by the cam as it revolves, and the valve is lowered so quickly as to have the effect of being actually released and allowed to drop to its seat, while at the same time it is supported by the lifter. The interval between

the full lift of the valve and the reaching of the offset by the highest point of the cam determines the point of cut-off, and insures sufficient lift of the valves. The advantage claimed for this arrangement is, that by keeping the valve always supported while open, the danger of slamming is avoided without the necessity of a dash-pot, which, in cases where the valve is tripped or released, is absolutely indispensable.

When these engines are started, and until the speed for which the governor is adjusted is reached, the steam necessarily follows full stroke, as the cut-off is inoperative. But as soon as the regular speed is attained, the motion of the governor thrusts the centre arm of the rack-shaft downward, thereby causing the arms to which the lifting toes are connected to move towards the cylinder. This brings the offsets of the lifting toes nearer to the cams, causing them to drop sooner, thus cutting off the steam at the proper point. In case of the removal of the entire load from the engine, induced by the breaking of a belt, etc., the governor, owing to its positive motion, will effectually check any attempt at "running away," as the offsets on the lifting toes will be thrust so far inward, that the cams will not raise the valves from their seats until the speed is again reduced to the proper point.

It is claimed that, under the above-mentioned circumstances, the engine will not make one full revolution before being completely under the control of the governor. All the sliding and bearing surfaces of the valve-gear of these engines are made of hardened steel, thus preventing the liability of rapid wear, and also requiring very little power to move the valves. The fly-wheels are turned on the face and edges. The shafts, crank-pins, and connecting-rods are made of the best material, and the bearings are ample and well proportioned. The workmanship is excellent, and the finish neat and attractive. In fact, these engines rank among the most simple, durable, and economical in the country. They are manufactured by the Putnam Machine Company, Fitchburg, Mass. |

|

1884 Putnam Machine Co., Steam Engine

1884 Putnam Machine Co., Steam Engine

|

|