|

Title: |

1901 Article-Rogers & Hemphill Machine Co., Vertical Boring Mills |

|

Source: |

Iron Age 01 Aug 1901 |

|

Insert Date: |

2/18/2011 9:29:11 AM |

Rogers & Hemphill Machine Company.

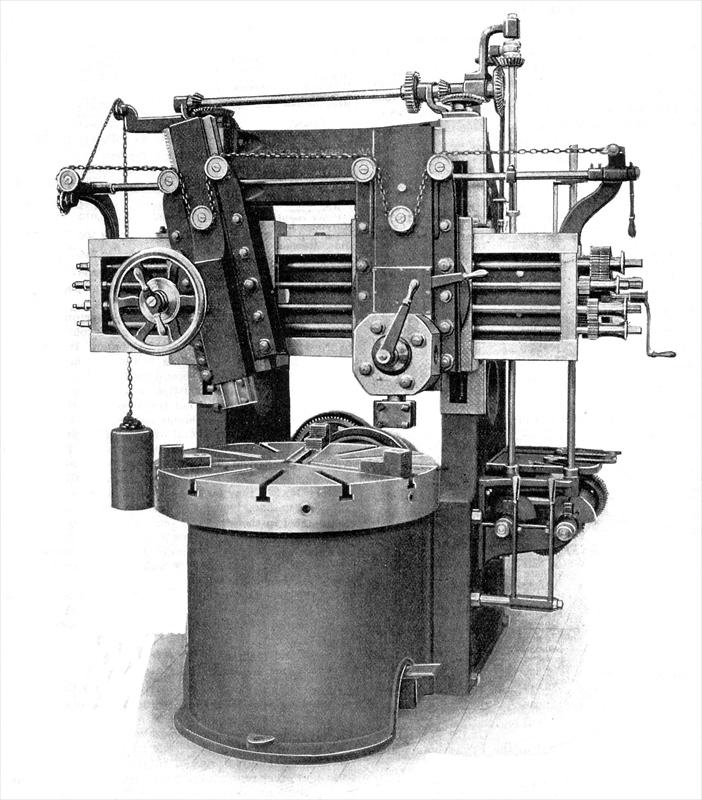

Two machines of admirable design are shown by the Rogers & Hemphill Machine Company of Alfred. N. Y. for whom the Prentiss Tool & Supply Company. 115 Liberty street. New York, are the selling agents. The first mill illustrated will take work up to 44 inches in diameter. It is provided with one regular head and one head carrying a swivel turret stake fitted with a turret having four holes 2 1/2 inches in diameter for the boring bar, tool holder, &c The turret is held and securely locked in position by a clamp and lock levers. While each head is entirely independent of the other in oper-ation, the feed mechanism is so arranged that both heads may be run in unison. The feed rods and screws run the entire length of the cross rail, thereby allowing either head to be carried to the center for boring.

The table is very large and heavy and contains a three universal chuck of 38 inches diametrical capacity, and, fits in junction with the base, over the ring gear and pinion in such a way that it is almost impossible for chips to get into the gearing. The webbed side frames extend to the floor, and the manner in which they secured to the base insures great rigidity. The rails are raised by power, the lift screws being built into the housings and driven by gears in direct connection one, of the regular feed shafts. The automatic trip for the cross and vertical feeds is adjustable to any desired position. There is a brake, operated by the foot lever shown, for stopping the table at the will of the operator All of the levers are placed within convenient reach The feed gearing is all positive, the changes being obtained by means of pull pins. The regular head has -nine changes of feed and the other 21, the changes being so arranged that any standard thread from 2 to 12, including 11½, may be cut. The table has 20 changes of speed. The drive cone and back gears are placed between the housings, the result being a compact. self contained machine, requiring comparatively little floor ace.

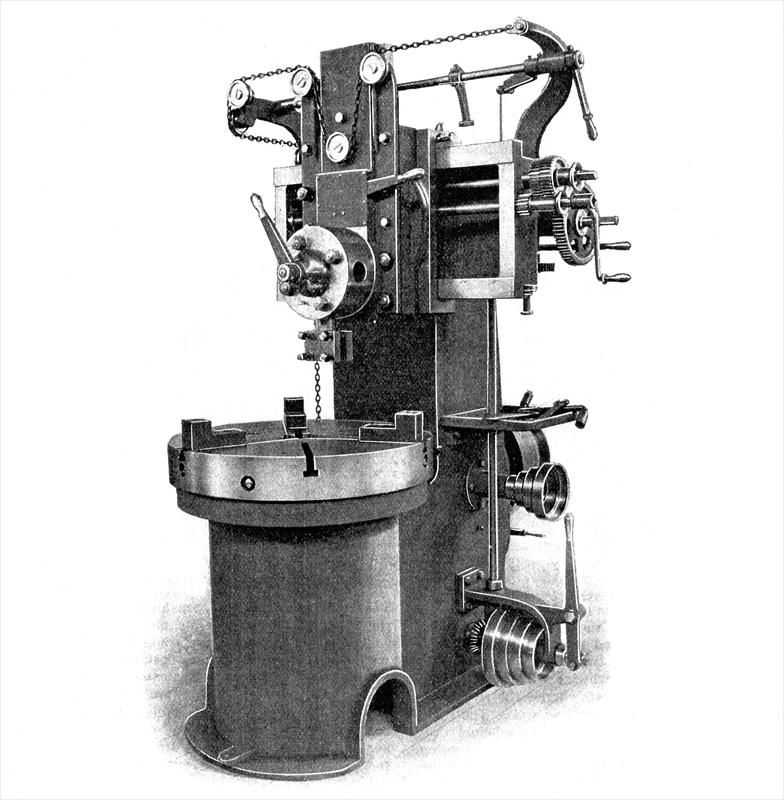

Single Head Mill.

The second engraving is of a 31-inch single head swivel turret mill designed to meet the requirements for a simple machine occupying little floor space, and capable of doing accurate work. The turret carries four tools. The swivel is adjustable to any angle, and is graduated. A three-jaw universal chuck is built into the table, and both the table gear and pinion are ac-curately planed. Both vertical and horizontal feeds are provided with an adjustable automatic or hand trip. cone has four steps. There are 16 changes of speed to the table, and eight feed changes. The tool will take 14 inches under the rail.

speed to the table, and eight feed changes. The tool will 14 inches under the rail. |

|

1901 Rogers & Hemphill Machine Co., Vertical Boring Mill

1901 Rogers & Hemphill Machine Co., Vertical Boring Mill

1901 Rogers & Hemphill Machine Co., Vertical Boring Mill

1901 Rogers & Hemphill Machine Co., Vertical Boring Mill

|

|