|

Title: |

1911 Article-Lancashire Dynamo & Motor Co., Ltd., Planer with Lancashire Reversing Motor Drive |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V2, 1911, pgs. 40-42 |

|

Insert Date: |

5/14/2020 8:17:42 PM |

|

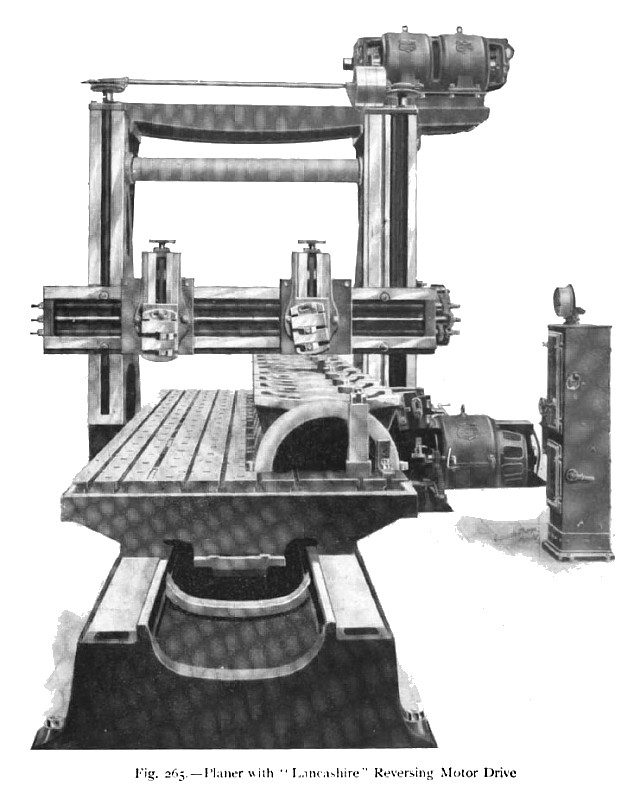

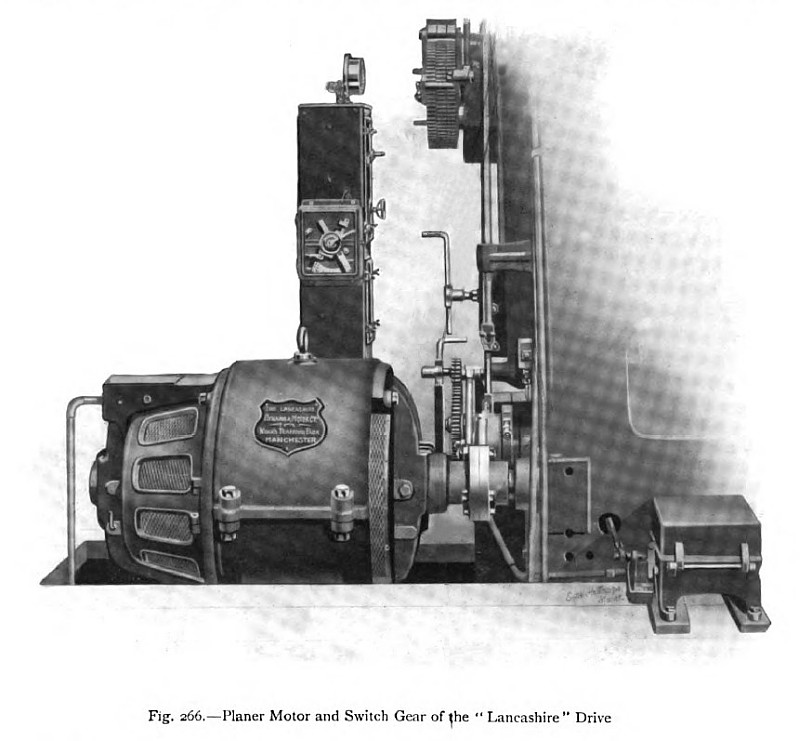

In the electric-driving system, introduced by the Lancashire Dynamo and Motor Company, Ltd., the chief difficulties of the variable-speed motor driving system are overcome. Instead of reversing and varying the strength of the motor field by reversing the connections and inserting resistances in the field circuit, the reversal of the motion and the variation of the speed are effected in the Lancashire system by reversing the direction of the current sup- plied to the motor and by varying the voltage. At some convenient position near the machine, or on the upright of the machine itself, there is mounted a motor generator the motor portion of which is supplied with current from any available source of supply. The generator supplies continuous current to a motor coupled directly or suitably geared to the driving shaft of the machine. By means of a reversing switch and a controller the generator field can be reversed or varied, and thus by reversing the direction of the generator current and varying the voltage the direction of rotation and speed of the motor can be readily controlled. The reversing switch is actuated by a tappet from the reversing gear of the planer, and at the same time the generator voltage is varied to suit the speed desired, either for the cutting or for the return stroke. Hand gear is provided, in addition, for operating the speed controller to suit the work on the cutting stroke, the return stroke being performed generally at a constant high speed; but arrangements may also be made for varying the return stroke. Sometimes it happens that during a portion of the forward or cutting stroke the tools are not in actual operation, and in such cases time may be saved by so arranging the gear that the table travels at the fast return speed during the idle portions of the cutting stroke. A system of the kind described above is regenerative, as the energy stored in the table load and in the rotating portions of the planer and motor is returned to the circuit at each reversal. At such times the motor is driven by the table, and becomes a generator supplying current through the motor generator to the main-supply line. A considerable saving in power is thus effected, and in addition there is a braking action, which facilitates the quick reversal of the motion. It is claimed that the control is such that machines driven in this way can plane up to a line with greater regularity than is possible on ordinary belt- driven machines fitted with spring or other similar regenerative devices. Fig. 265 illustrates the application of the system to a 6 ft. x 6 ft. x 18 ft. planer, and fig. 266 is a separate view of the motor and switch gear. On an extension of the cross brace at the top of the upright is mounted the motor generator. As has been already explained, the motor is driven by current from the supply mains, and the current produced by the generator is used for driving the motor coupled directly to the driving shaft of the machine. If desired, however, the motor portion of the motor generator may be dispensed with, the generator being belt-driven from a line of shafting. Switch gear of the ordinary kind is provided for starting and stopping the motor generator, and, by means of a rheostat, for varying the strength of the generator field. The only moving switch is the reversing switch, actuated by a tappet rod from the reversing gear. |

|

1911 Lancashire Dynamo & Motor Co., Ltd., Planer with Lancashire Reversing Motor Drive

1911 Lancashire Dynamo & Motor Co., Ltd., Planer with Lancashire Reversing Motor Drive

1911 Lancashire Dynamo & Motor Co., Ltd.-Planer Motor Drive & Switch Gear

1911 Lancashire Dynamo & Motor Co., Ltd.-Planer Motor Drive & Switch Gear

|

|