|

Title: |

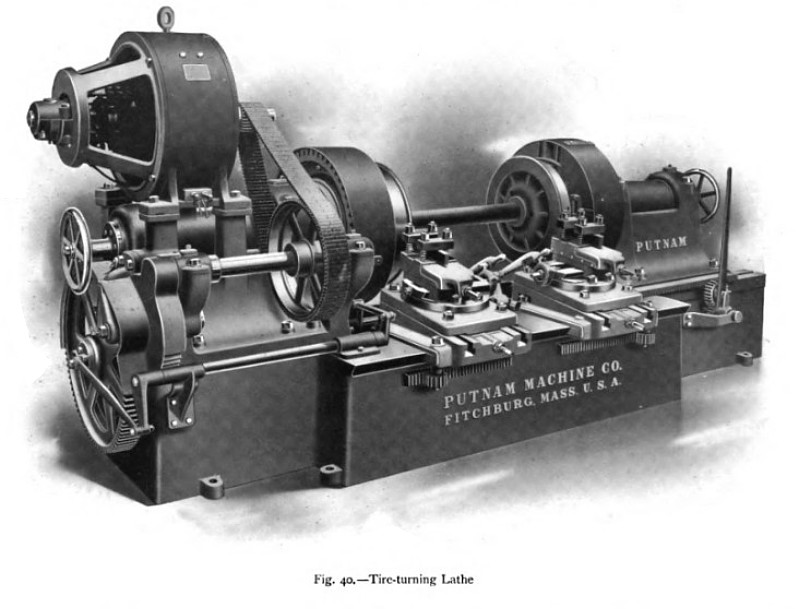

1911 Article-Putnam Machine Co., 42 in. Tire Turning Lathe |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pgs. 36-37 |

|

Insert Date: |

4/1/2020 2:00:07 PM |

|

A 42-in. steel tire turning lathe, manufactured by the Putnam Machine Company, of Fitchburg, America, for the simultaneous turning of both tires of railway coach and truck wheels when mounted upon their axles, is illustrated in fig. 40. The machine is of massive construction, and is capable of undertaking, without vibration, the heaviest duties necessary for such work. This massiveness of construction is especially noticeable in the case of the bed, which is solid on the top, and is internally braced and rigidly cross-tied. The fast headstock is bolted securely to the bed, and the tailstock, the face-plate of which is power-driven, is longitudinally adjusted by means of a separate countershaft or motor, or a rack-and-pinion hand arrangement, which provides the required purchase for moving the heavy tailstock. Each of the power-driven face-plates is mounted upon a large-diameter charcoal iron spindle, which extends through the face-plate and has a taper hole for the purpose of engaging taper journal bushings, used in the turning of coach wheels. When truck wheels are being operated upon, split guides or supports are bolted to the face-plates, and steel centres are run out through them to engage the axle centres. The split guides are then tightened so as to grip securely the steel spindles. This arrangement permits of the tyres being brought close up to the face plates in all cases, and thus the maximum rigidity of mounting is obtained. Five driving dogs of a novel and patented form are mounted upon each of the face-plates. These driving dogs automatically engage the work when it is placed between the centres, and thus, unlike the customary devices, they do not necessitate any movement or adjustment to make them operative. Each dog automatically adjusts itself to the force of the cut, and as the force is thus uniformly distributed, there is no tendency for one portion of the tyre to be sprung more than another, as readily happens |

|

1911 Putnam Machine Co., 42 in. Tire Turning Lathe

1911 Putnam Machine Co., 42 in. Tire Turning Lathe

|

|