|

Title: |

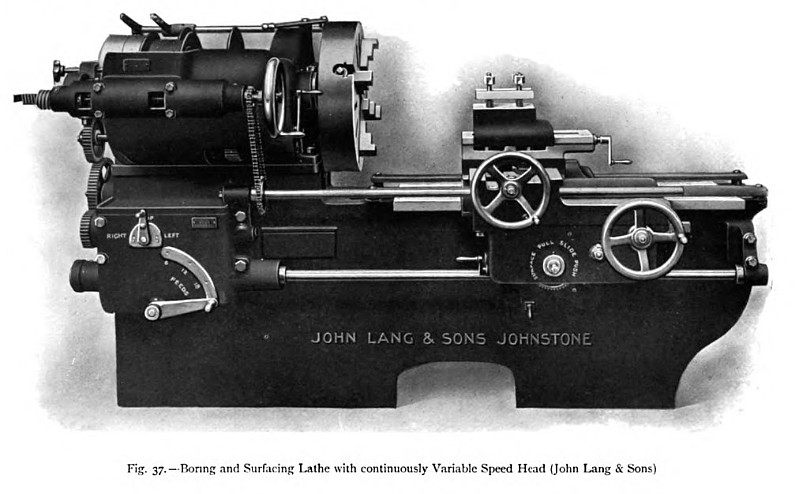

1911 Article-John Lang & Sons, Boring and Sufacing Lathe |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pg. 33 |

|

Insert Date: |

3/31/2020 8:48:27 PM |

|

A boring and surfacing lathe, by Messrs. John Lang & Sons, of Johnstone, is illustrated in fig. 37. This lathe, which has a swing of 18 in., is intended for the surfacing of cylinder covers and similar work, and when desired the necessary gear for screw - cutting can be provided. Certain of the essential parts have already been described in full detail when dealing with Messrs. Lang's 12-in. centre engine lathe. Thus, the head is of the patent treble-geared variable-speed type with, however, an automatic control of the speed variation from the transverse feed of the tool slide. If, in the surfacing of work of any considerable diameter, the speed of rotation is constant the surface speed near the periphery will probably be too great; while, on the other hand, the speed towards the centre will be undesirably slow from the point of view of output. It is therefore desirable to increase the speed of rotation of the work as the tool moves from the periphery towards the centre, and more especially is this required when the surface is of large diameter. To obtain this effect the controlling hand wheel of the variable gear is chain driven from a shaft which rotates in conformity with the transverse motion of the tool slide, and thus, as the tool passes over the surface, a constant cutting speed is automatically maintained. The time taken to finish the surface is considerably reduced compared with the time taken with the ordinary cone drive, especially when the operator omits to change the position of the belt when the faster speeds are required. The gearbox at the left end of the bed is of the type already described, with the exception of the screw-cutting feeds, which are not provided in the example illustrated. Motion of the small lever towards the right or the left, as the case may be, reverses the direction of rotation of the feed shaft, and the position of the long lever determines the feed, which may be either 1/6 in., 1/12 in., 1/18 in., or 1/24 in. Transverse motion of the slide rest for surfacing operations is obtained by pulling outwards the knob on the apron and thus connecting the slide-rest screw to the feed shaft, and a hand wheel is also provided for the same operation. By pushing the knob inwards, the carriage is fed along the bed. For quickly moving the carriage, the hand wheel shown at the right of the apron is provided. |

|

1911 John Lang & Sons, Boring and Sufacing Lathe

1911 John Lang & Sons, Boring and Sufacing Lathe

|

|