|

Title: |

1872 Article-Charles R. Tompkins, Champion Molding Machine |

|

Source: |

Manufacturer & Builder, V4, Sept 1872, pg. 207 |

|

Insert Date: |

4/23/2019 8:36:07 PM |

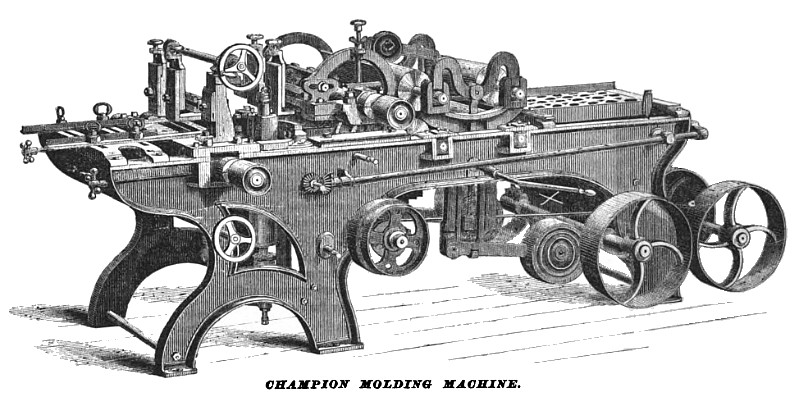

THE old way of making moldings was by hand, using a plane of which the lower surface and chisel was the counterpart of the molding intended. For this reason, carpenters of olden time, wanted many kinds of molding planes, and this is still the case in all out of the way places where mechanically made moldings cannot be had. By the invention of the molding machine this labor is saved, as now several hundred kinds of moldings of all necessary shapes and sizes can be had at so low prices, that no carpenter or cabinet-maker will ever think of making them by hand, when there is possibility of purchasing them ready made. Of course, the machines to make them with have continually been improved, till at last a machine was produced and patented by C. R. Tompkins, of Rochester, N. Y., which for its superior qualities has been called the Champion Molding Machine. It is represented in our figure; it is adapted to every kind of molding, from the smallest and simplest to the largest and most intricate. It works all four sides at once, and the top and bottom cylinders are hung between the bearings, so that there is no tremble when working on heavy hard wood moldings. The top cylinder is twelve and a half inches long, six inches in diameter, and has four sides. Two or four cutters can bo used, and as the bolts that hold the knives work in slots, the cutters can be fastened anywhere on the cylinder. The lower cylinder has four sides also, and the length of knife on each is twelve inches, the cylinders run on cast-steel shafts one and three fourths inches in diameter, with self-oiling boxes and steps and are driven by two pulleys four and a half inches in diameter and four and a half inches face, one on each side of the machine. The bottom cylinder is also raised and lowered, so as to regulate the cut from one thirty-second to three fourths of an inch, and the under press-plate is adjustable also, making it very convenient to operate.

The side cutters run upon cast-steel spindles one and a half inches in diameter, in patent self-oiling steps, with chip breakers, and are furnished with one pair of three-winged matcher heads, with cutters for matching lumber, and one pair of two winged heads for jointing. It has two pair of feed rolls six inches in diameter, with expansion gear, weighted levers, etc. The rolls are lowered and raised both ends at once, with an improved lifting arrangement, by a crank at the side of the machine and shaft under the bottom rolls.

The frame is of iron, eight feet long, and very heavy. The counter shaft is attached to the machine in the same manner as our planers, and the cylinders, top and bottom, are driven in the same manner, which gives great power to the machine and renders it capable of doing the heaviest kind of work.

Beside working moldings, this machine is designed for double surfacing up to twelve inches wide, matching flooring, ceiling, and planing and jointing, siding, making pickets, stair rail, fence rail, etc., etc. In fact, it is the most available machine ever gotten up, and almost any kind of work can be done on it that can be done with a planer and matcher and molding machine.

The driving pulleys are twelve inches in diameter, and six inches face, (tight and loose,) and run 900 revolutions per minute.

The weight is 3400 pounds, and the price is $750.

US Patent: 71,341

http://www.datamp.org/patents/displayPatent.php?number=71341&typeCode=0 |

|

1872 Charles R. Tompkins, Champion Molding Machine

1872 Charles R. Tompkins, Champion Molding Machine

|

|