|

Title: |

1865 Article-Charles Merrill & Sons-Hotchkiss's Atmospheric Hammer |

|

Source: |

Scientific American, V13, 16 Sept, 1865, pg. 178 |

|

Insert Date: |

1/4/2018 7:54:34 PM |

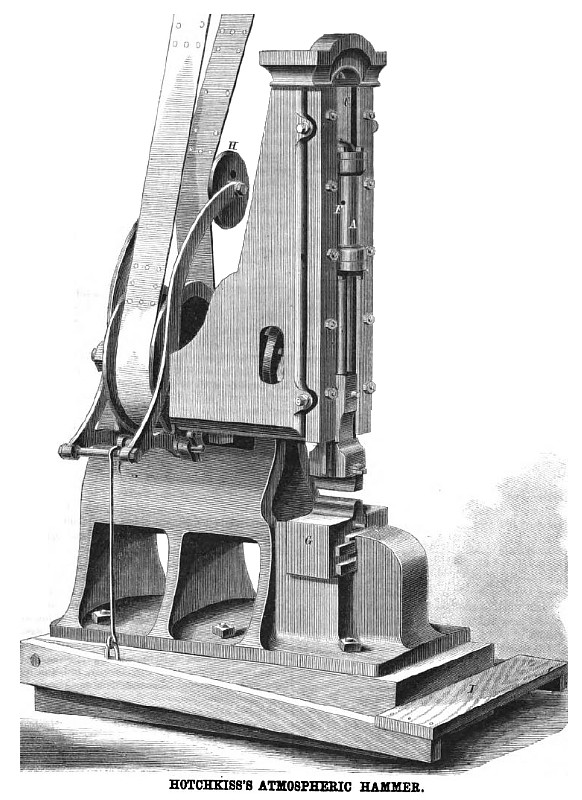

Improved Atmospheric Hammer

This hammer is highly approved of by many of our largest machine makers, and over forty are now in use in different parts of the country. It can be managed with great accuracy, will strike a light or heavy blow, runs rapidly, and is under perfect control. We regard it as a useful machine where die or other work has to be done. We never publish certificates in connection with our illustrations, and are therefore obliged to omit those shown us by the manufacturers, who will be happy to furnish them by mail. This hammer works by compressing air in the cylinder, the cylinder itself sliding up and down between guides. The following description will render it in

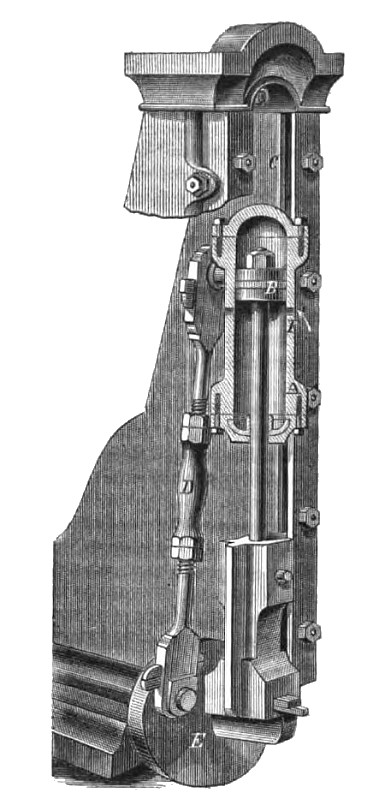

The air is compressed by a cylinder, A, and piston, B (see Fig. 2). The cylinder moves in the slides, C, by the action of the connecting rod, D, driven from the face plate, B, by belting, in the usual manner. There are two small holes, F, in the cylinder, A; through these the air enters. The whole machinery is carried in a strong iron frame. Now, if we suppose the cylinder to ascend, the air will enter through the holes, F, and be compressed as the cylinder goes up. This compression is at the bottom of the cylinder, and therefore lifts the hammer moving in the slides. By the time the hammer is lifted the connecting rod arrives at the top center and commences to descend. The air then enters above the piston, and as the cylinder still comes down condenses the volume very highly. This condensed air Is the stored up to make the blow, for so soon as the connecting rod turns the bottom center, the confined air expands instantly and thus throws the piston and hammer down with great force. This action is repeated at every revolution, and the height of the cylinder is altered so as to forge large or small work by lengthening or shortening the connecting rod. The hammer is lifted at the ascending stroke by the compressed air below, as we stated previously, and this also aids the cylinder in compressing the air for the return blow, and it is owing to the rapid action of the two movements that the piston does not fall before it obtains the advantage of the air compressed above it.

It will be seen that this hammer is exceedingly simple in its construction; there are no valves about it to get out of order, and the packing is exceedingly durable and easy working. Both that in the piston and in the cylinder head is made of the cup-leathers used in packing hydraulic rams, and they have run for months without leakage or perceptible wear. The dies are fastened in with keys, and the anvil block, G, is adjusted by another key, so that the dies can be set properly without delay. The speed of the hammer is regulated by an idler pulley, H, which can be operated by the treadle, I.

The patent bears date May 3, 1864, and was issued to Bennett Hotchkiss, of New Haven, Conn. For further information address the sole manufacturers, Charles Merrill & Sons, 556 Grand Street, New York City.

US Patent: 42,581

http://datamp.org/patents/displayPatent.php?number=42581&typeCode=0 |

|

1865 Charles Merrill & Sons-Hotchkiss's Atmospheric Hammer

1865 Charles Merrill & Sons-Hotchkiss's Atmospheric Hammer

1865 Charles Merrill & Sons-Hotchkiss's Atmospheric Hammer (Cut-Away View of Head)

1865 Charles Merrill & Sons-Hotchkiss's Atmospheric Hammer (Cut-Away View of Head)

|

|