|

Title: |

1918 Article-Thompson Grinder Co., Universal Tool & Cutter Grinder |

|

Source: |

Machinery Magazine, V24, Aug 1918, pg. 1158 |

|

Insert Date: |

12/11/2017 7:44:24 PM |

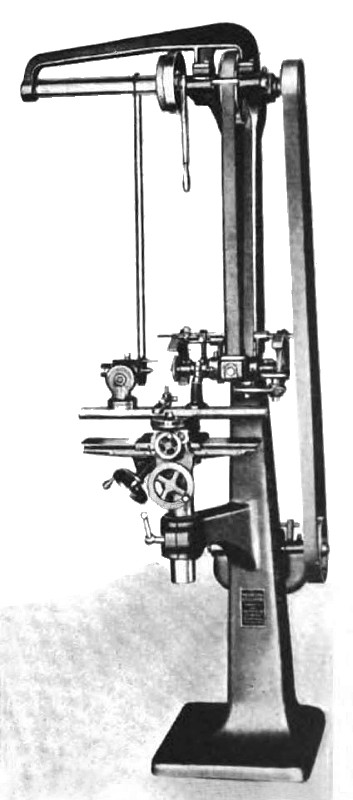

THOMPSON UNIVERSAL CUTTER AND TOOL GRINDER

The universal cutter and tool grinder now being manufactured by the Thompson Grinder Co., Springfield, Ohio, was designed for sharpening all forms of cutters and reamers and, in addition, for performing all the circular, internal, and surface grinding likely to occur in the manufacture of cutters, reamers, counterbores, drill bushings, arbors, and small machine parts. There are three different types of drive for this machine. The particular grinder shown in the accompanying illustration is a self-contained, belt-driven design, having a jack-shaft on the rear of the column. This self-contained design may also be arranged with a motor drive, the motor being attached to the rear of the column. The third type of drive is belt-driven from a countershaft.

This universal grinder may be used for such operations as sharpening spiral milling cutters, side milling cutters, inserted tooth face mills, end-mills, large or small saws, gear-cutters, form cutters, taps, counterbores, reamers, etc. When sharpening side milling cutters, the teeth may be given either straight or concave clearance. The universal head provided with this machine is so arranged that the tool or cutter may be held in any position that may be required relative to the wheel. This head is adjustable in either a horizontal or vertical plane, and it is provided with a bearing which. In conjunction with bushings, collets, or arbors, may be used for holding various cutting tools in position. As end-mills must of necessity be provided with collets, they can be held securely and accurately by the taper shank and, at the same time, be revolved in a substantial bearing which insures grinding the teeth accurately.

In order to increase the range of this machine, it may be equipped with attachments for cylindrical grinding, internal grinding, surface grinding, concave and convex grinding. The cylindrical grinding attachment is shown applied to the machine in the illustration. This attachment includes the drum for the countershaft with hangers and a weighted lever, a universal head spindle with a pulley for a quarter-inch round belt, a universal chuck, a faceplate with a draw-in collet, and an adjustable dog. The internal grinding attachment is used in connection with the circular grinding attachment. The driving pulley is mounted on the grinding wheel spindle in place Of the Thompson Universal Cutter and Tool Grinder grinding wheel. The attachment is held on the front of the machine in such a way that the belt may easily be tightened.

When the machine is used for surface grinding, the carriage is swiveled at right angles to the grinding wheel spindle and the work is traversed directly under the grinding wheel, the cross-feed being obtained by means of the cross-slide screw. This attachment can be held in the universal head for grinding at any angle. The concave and convex grinding attachment is used when cutters having circular edges are being ground. The center of the attachment is located directly under the front edge of the grinding wheel and the cross-slide is fed in or out to suit the radius required. This attachment is not a part of the regular equipment. Cutter grinding is performed on the left-hand side of this machine, while the right-hand side is arranged for tool grinding. The tool grinding does not interfere in any way with the use or adjustment of the cutter grinding side. |

|

1918 Thompson Grinder Co., Universal Tool & Cutter Grinder

1918 Thompson Grinder Co., Universal Tool & Cutter Grinder

|

|