|

Title: |

1877 Article-Frick & Co., Eclipse Agriculural Portable Steam Engine |

|

Source: |

Scientific American, V36, 17 Feb 1877, pg. 95 |

|

Insert Date: |

4/12/2017 1:23:47 PM |

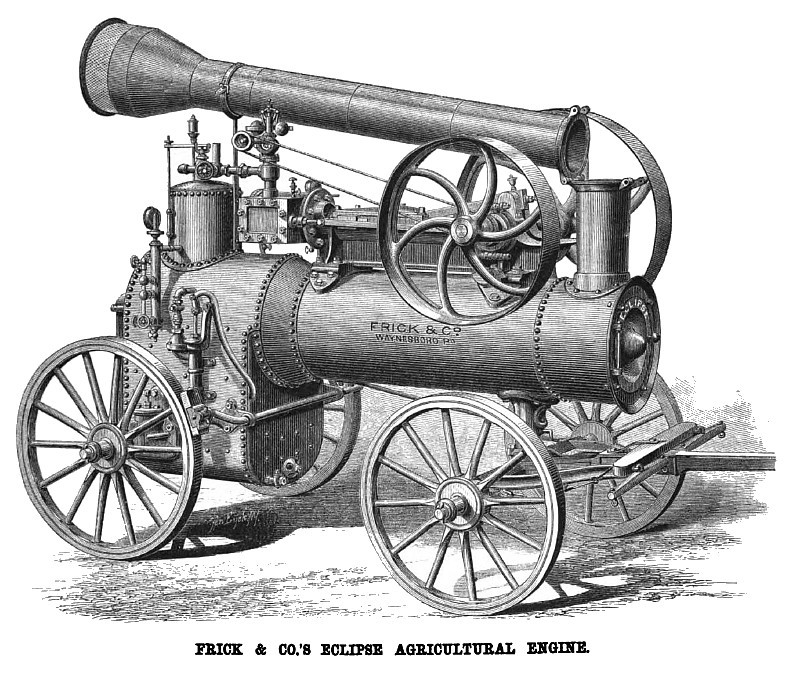

We illustrate here with the well-known “Eclipse” engine, mounted on wheels to adapt it for farmers' uses. The machine as thus arranged, the manufacturers inform us, vanquished all competitors at the Cincinnati Industrial Exhibition of 1874, and also during the field trials held under the auspices of the Centennial Commission, giving in both cases the most power with the least consumption of coal and water. From testimonials from parties using the engine, submitted to us, we learn that, with an 8 horse machine, 1,600 bushels of wheat were threshed with three fourths of a ton of coal and only five hogsheads of water. Another writer states that, with a 10 horse power engine, he is able to saw 3,000 feet of 1 inch oak timber per day, using a 48 inch saw. We have been obliged to obtain our information regarding the construction and advantages of this engine mostly from a pamphlet issued by the manufacturers; but from what we learn from other sources, we believe the Eclipse engine possesses all the qualifications herein stated.

The engine is of the horizontal style, the cylinder and steam chest being made in one casting. All of the exposed parts are felted and covered with iron. The frame or bed which comprises the cylinder head, the guides for . the crosshead, and the two bearings for the crankshafts are also cast solid; so that it is impossible for the important working parts to get out of line. In shape, the bed is the half of a horizontal hollow cylinder, excepting a small portion of one extremity, which is an entire cylinder, which is a flange to which the cylinder and steam chest casting is bolted. The form of the bed enables all waste oil to be caught and afterwards led away by a suitable tube. The cylinder, being secured to the bed at one end only, is free to expand; and as the cylinder, steam chest, slide valve, and piston rod lengthen in the same direction, the engine will have the same lead and clearance when working as when cold. The pillow blocks are lined with anti-friction metal, and are provided with means for taking up lost motion. The crank shaft is double, made of forged iron, and is counterbalanced so that its motion is smooth and equable, even when at high speed. The piston has a metallic packing ring, and is self-adjusting; the piston rods are of steel. The pump is driven direct from the crosshead, its valves may be readily removed without disturbing the connections, and the water supply is easily regulated. A heater consisting of a large cast iron pipe, bolted near its end to the steam cylinder and supported by a bed bracket, receives the exhaust steam on its way to the smoke stack. The steam warms the feed Water, the conduits of which pass two or three times through All necessary fittings in the way of air cocks, self-feeding oil cups, governor, etc., are added; and the various parts are manufactured by special machinery so that they can be accurately duplicated.

In the boiler, which is of locomotive style, the water space extends entirely around the fire box and ash pit, the water circulating in the circular water bottom and thus preventing the accumulation of deposits. Each generator is made of the best boiler plate iron, the tubes are lap-welded, and a cold-water pressure of 200 lbs. to the square inch is guaranteed to be withstood.

The wheels of the wagon have cast iron hubs, and are large enough to raise the boiler sufficiently to enable the forward wheel to pass underneath, so that the entire vehicle can be turned on a small space. The axles are of the best refined wrought iron; and strong cast iron brackets, containing spiral steel springs, sustain the weight of boiler and engine, thus enabling the machine to be moved over the roughest roads without injury. The springs are easily accessible for repair or adjustment, without dismounting engine or boiler. A new and powerful brake is used on the wheels. The fly wheels are turned smooth and true for belts, and are large enough to give the proper speed for threshing wheat, etc. The smoke stack is hinged, as shown in the engraving; so that, for storing or transportation, it can be laid down out of the way. It is also provided with an efficient device for arresting and extinguishing the sparks. This, we are informed, has been tested by putting straw and other combustible material on the smoke stack, without its taking fire. The ash pan also has a close-fitting door, to prevent danger from that source. For further information, address the manufacturers, Messrs. Frick & Co., Waynesboro’, Franklin County, Pa. |

|

1877 Frick & Co., Eclipse Agriculural Portable Steam Engine

1877 Frick & Co., Eclipse Agriculural Portable Steam Engine

|

|