|

Title: |

1871 Article-Witherby, Rugg & Richardson, Tenoning Machine |

|

Source: |

Manufacturer & Builder, V3, Jan 1871, pg. 16 |

|

Insert Date: |

2/21/2017 12:30:44 PM |

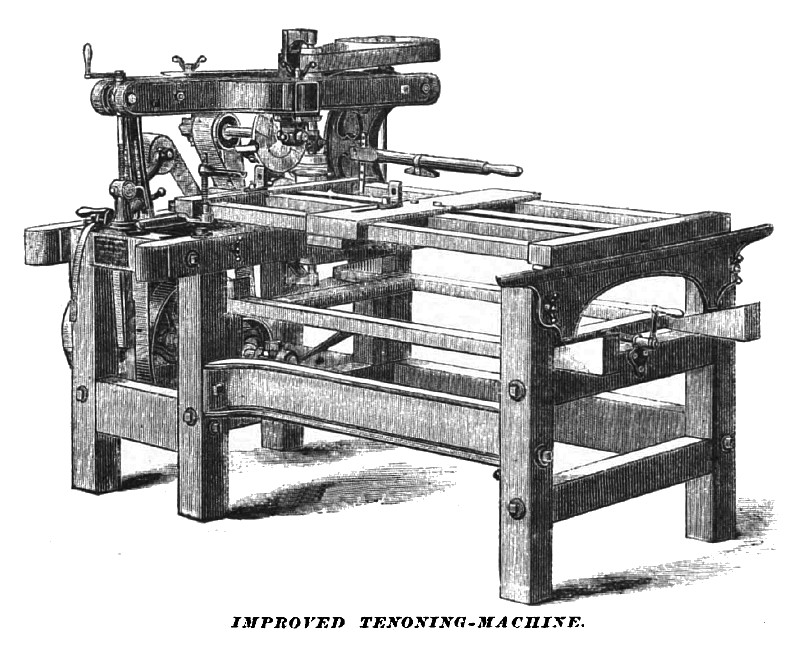

Improved Tenoning-Machine

The tenoning machine has long been in use, and the great saving of skilled mechanical labor effected by it is felt by everyone, to whom savings are perceptible at all, in the cheapness and abundance of window-sash and doors In all classes of dwellings, as well as in the price of framed furniture in general. In principle, there is not much difference among the several varieties of this machine; but there has been room for improvement in point of convenience and workmanship. Has been, we say; for an inspection of the beautiful machine illustrated in this article shows little if anything left to be desired. The workmanship is strikingly neat and perfect, and the same may be said of the proportions of the design. The principal conveniences to be pointed out are as follows: The bed moves on planed iron slides or ways, the right-hand one being seen at the end and top of the frame, where it is bolted on. Right under it is seen tint wedge-frame, with wedges at the four corners, and the screw and crank by which the wedges—faced with smooth iron—are pushed under the ways or drawn back, so as to raise or lower the bed for the adjustment of the stuff to the under cutter. The upper cutter is adjusted to the work by the screw and crank at the upper forward left-hand corner. The forward end of the upper cutter-frame or yoke, which is raised and lowered by the screw, is hollowed off' toward the left, so as to clear the view of the cutters and the work. Likewise, the horizontal beam in the frame, at the place where the workman stands, is of iron, and curves inward out of the way,' permitting the workman to stand straight and close up to his work. The handle seen parallel with the back of the bed is brought around forward at right angles, in use, and pressed down by hand upon the stuff'. The handle fits in the hollow of the short horizontal arm of iron seen on a screw standard at the forward left-hand corner of the bed. This arm is run down on the screw to the desired position, and when grasped with the handle resting in its hollow, gives the whole contractile strength and firmness of the hand to the pressure on the stuff. When the frame of the upper cutter is raised or lowered in adjustment to the work, the tension or slackening of the belt which would result is corrected by the strap which hangs from the extreme left-hand corner of the frame. It runs to the frame of the tension pulley, and is held, after adjusting the tension, by a lever-key, the handle of which is seen in the cut. The screw by which the top cutter is adjusted horizontally, with reference to the depth of the tenon, is not in sight; but the set screws are seen on the top of the cutter-frame, by which, this cutter is held in place after adjustment. The small horizontal cutter behind the main vertical ones is the cope-cutter for sash, furnished to order. This machine is calculated to work stuff from one to four inches in thickness, and of any width. With all its superior conveniences and finish, it is afforded at the same price with other tools of the kind. It is manufactured by Wltherby, Rugg & Richardson, Worcester, Mass., and can be seen in New-York at 42 Cortlandt Street.

US Patent: 89,245

http://www.datamp.org/patents/displayPatent.php?id=2551 |

|

1871 Witherby, Rugg & Richardson, Tenoning Machine

1871 Witherby, Rugg & Richardson, Tenoning Machine

|

|