|

Title: |

1921 Article-Van Norman Machine Tool Co., Relio Bench Grinding Machine (Part 1) |

|

Source: |

Machinery, V28, Dec 1921, pgs. 326-327 |

|

Insert Date: |

6/26/2016 10:00:37 PM |

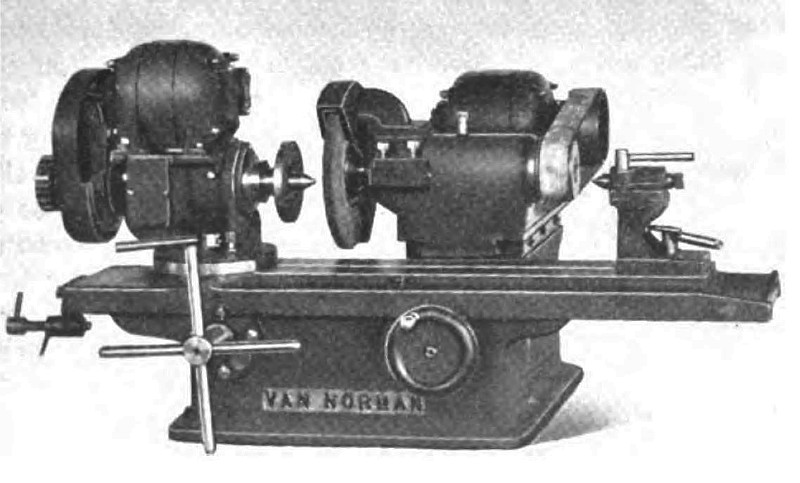

To meet the requirements of garages and automobile repair shops, the Van Norman Machine Tool Co., 160 Wilbraham Ave., Springfield, Mass., has developed the bench machine shown in the accompanying illustrations, which is suitable for grinding pistons, valves, wrist-pins, etc., re-grooving pistons, and for any other grinding or turning operation within its capacity. This machine is sold under the trade name of "Van Norman Relio." An individual motor drive is supplied for both the wheel- and work-heads, the wheel-spindle being connected to its motor by a belt, while the work-head spindle is driven through reduction gears direct-connected to the armature shaft of a motor mounted on top of the work-head. The wheel-spindle is equipped with ball bearings, and is located with its motor on a slide that may be moved transversely relative to the table.

The work-head spindle revolves in a taper bearing that may be adjusted to compensate for wear of the engaging surfaces. This head may be swiveled on the table and set at any angle from the center line of the table up to 50 degrees. Graduations on the base of the head facilitate these settings, and locating holes at 0, 30, and 45 degrees insure the same settings on subsequent pieces when grinding valves, reamers, etc. A tailstock is provided for holding work between centers when this method of support is desirable.

The table may be traversed past the grinding wheel through the rotation of a hand-wheel, and adjustable stops are supplied to limit this travel.

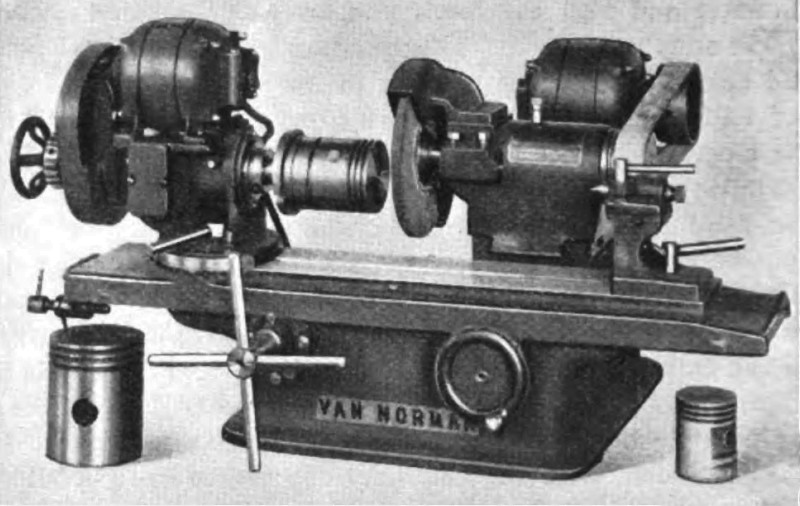

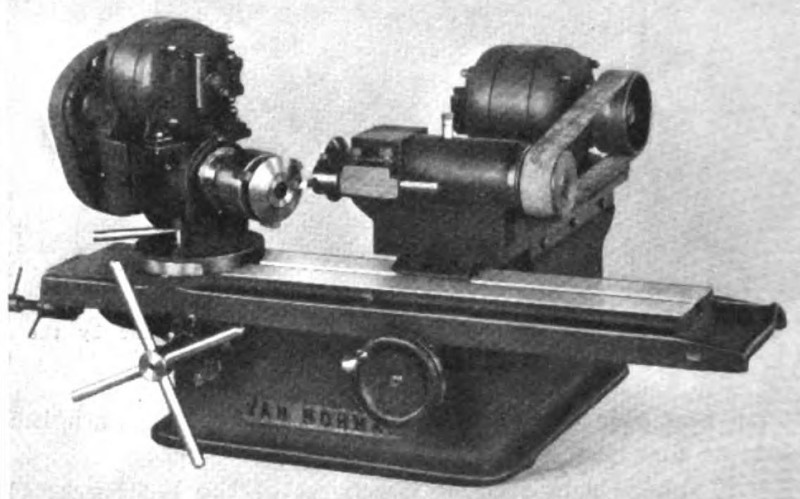

In Fig. 2 the "Relio" grinder is set up for grinding pistons, an attachment being mounted on the work-head spindle to enable the work to be quickly loaded and unloaded. Any standard piston with either straight or tapered sides can be accommodated. By removing the wheel and guard from the grinding head and inserting a special holder with a turning tool in a socket of the wheel-head in front of the wheel-spindle, the grooves for the piston-rings may be re-machined. Another operation in which a turning tool may be effectively used on this machine is that of turning angular surfaces. This operation is illustrated in Pig. 3. The tool is fed over the face of the work by revolving the cross feed hand-wheel at the front of the machine. It will be seen that the work-head is placed at an angle to suit the angularity of the surface being machined.

Fig. 4 shows the machine set up for an internal grinding operation, a small-wheel arbor being attached to the front end of the wheel-spindle. Taper holes may be ground by setting the work-head to suit. Internal and external grinding can be performed at one setting of a piece of work by simply changing the grinding wheels. In the grinding of valves the head is set to the required angle and the valve stem is held in a draw-in collet chuck. It is stated that valves for standard cars are ground in less than one minute. Such an operation is illustrated in Fig. 5. Other operations readily accomplished on the machine are the grinding of wrist-pins, in which the work is held between centers and rotated by a key or pin inserted in the center of the work-head, provision being made for holding a wheel-truing tool on the tailstock; the grinding of tapers on valve cages; the grinding of valve reamers, in which a support finger is placed under the reamer teeth as they are being ground; and the repairing of armatures. In the last operation, the work is mounted between centers, and the worn parts may be finish-turned, scored or ground.

Some of the specifications of the machine are as follows: Size of grinding wheels, 8 by ½ inch and 1 by ¼ inch; swing of work-head, 8 inches; distance between centers, 12 inches; travel of table, 10½ inches; capacity of draw-in collet, ¾ inch; bench space required, 3 by 4 feet; size of wheel-head motor, ¼ horsepower; size of work-head motor, 1/8 horsepower. Low and high speeds of work-head spindle. 63 and 170 revolutions per minute, respectively; motor speeds, 1700 revolutions per minute; speed of wheel-spindle, 2800 revolutions per minute; and weight of machine, approximately 330 pounds. |

|

1921 Van Norman Machine Tool Co., Relio Bench Grinding Machine (Fig. 1)

1921 Van Norman Machine Tool Co., Relio Bench Grinding Machine (Fig. 1)

1921 Van Norman Machine Tool Co., Relio Bench Grinding Machine (Fig. 2)

1921 Van Norman Machine Tool Co., Relio Bench Grinding Machine (Fig. 2)

1921 Van Norman Machine Tool Co., Relio Bench Grinding Machine (Fig. 3)

1921 Van Norman Machine Tool Co., Relio Bench Grinding Machine (Fig. 3)

|

|