|

Title: |

1921 Article-Pawling & Harnischfeger Co.-Horizontal Boring, Drilling & Milling Machine |

|

Source: |

Machinery, V28, Oct 1921, pg. 150 |

|

Insert Date: |

6/21/2016 8:56:24 PM |

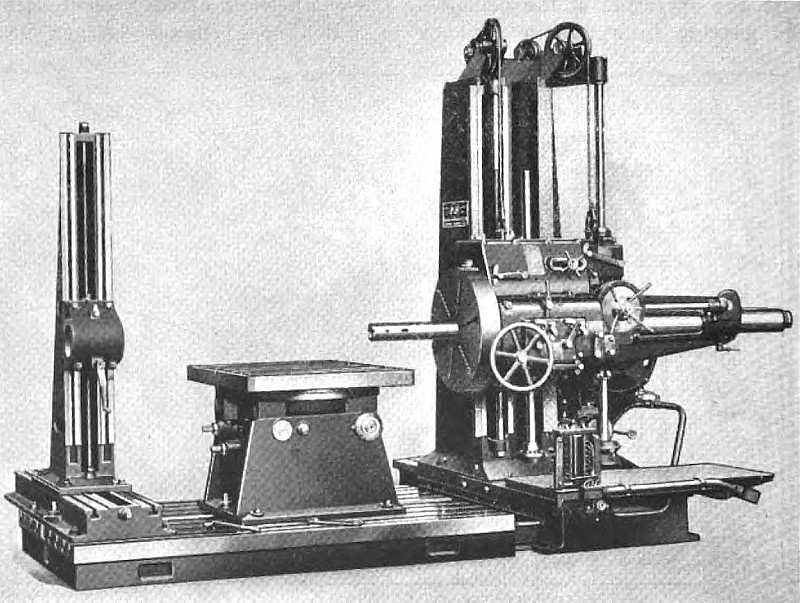

A new line of horizontal boring, drilling and milling machines, of which the No. 4-F machine shown in Fig. 1 is the smallest size, has been developed by the Pawling & Harnischfeger Co., 38th and National Aves, Milwaukee, Wis. These machines are especially designed for heavy milling and large boring operations, and can be used either as single-purpose machines or for general machine shop work. Among the features of the design are narrow guiding surfaces, take-up for all sliding parts, centralized control, and interchangeability of externally and internally driven faceplates. The back-gears are close to the spindle, and all driving shafts run at a high speed. Automatic stops are provided for the saddle and column of electrically driven machines. The column may be moved transversely on guides on the base by means of a screw. It may be traversed either forward or backward, by hand, power-feed or rapid traverse. The motor for driving the machine is located at the left-hand side of the column. The runway for the column is of a deep box section and is heavily ribbed.

The spindle saddle contains the drive for the spindle, the feeding mechanism, and the feed distributing mechanism. The main spindle sleeve bushing is made of phosphor-bronze, and is scraped to a slight taper so that wear of the sleeve may be readily compensated for. The saddle is guided on the column by a narrow guide located at the front. The feed-screw is located at the center of this guide. The saddle is counterbalanced by a weight inside the column, and is raised or lowered by a worm-wheel nut actuated by a screw. The raising or lowering of the saddle may be accomplished by hand, power-feed, or quick traverse.

The spindle is made from a high-carbon hammered alloy steel forging, and is ground to a sliding fit in the driving sleeve. Power is applied at the front end of the spindle while it is fed from the rear end through a rack and pinion.

The front end has a No. 6 Morse taper socket, and contains the necessary slots for driving milling cutters and boring bars. The drive is transmitted to the spindle either through a small faceplate with a wide-face, coarse-pitch gear or a larger faceplate with an internal gear of coarse pitch and wide face. These faceplates have slots and tapped holes to provide for the attachment of milling cutters and facing heads. The feed of the spindle on this machine is 36 inches; the minimum height of the spindle from a 9-inch bedplate. 25½ inches: and the maximum height, 73½ inches.

The machine may be driven by a 10-horsepower constant or variable-speed motor or by belt. The machine is double back-geared and, through the operation of three levers, eighteen reversible spindle speeds in geometrical progression, ranging from 5½ to 200 revolutions per minute can be secured. The boring and drilling feeds to the spindle are eight in number, reversible, and range from 0.0076 to 0.45 inch per revolution of the spindle. There are also eight reversible milling feeds to the column and the saddle, ranging from 0.009 to 0.54 inch per revolution of the spindle. The saddle and column have a rapid power traverse of 60 inches per minute.

All operating levers and hand-wheels are within easy reach of the operator and are conveniently arranged for the various operations. All levers are interlocking so that the engagement of two conflicting speeds or feeds at the same time is impossible. The work bed is provided with planed T-slots running parallel to the direction in which the spindle traverses. A planed squaring strip for aligning work is provided on three sides of the bed. The latter can be made to any desired size. The outer support, unless otherwise specified, has vertical and transverse movements of 48 inches. Graduated verniers reading to 0.001 inch are furnished for the main column and saddle and the outer support and saddle. A screw chasing attachment for cutting threads varying from 2 to 16 per inch and to any length within the capacity of the machine, can be furnished. A universal tilting and revolving table or a plain revolving table with movement by hand or power can also be furnished. The No. 4-F machine without bedplate, outer support, tables or electrical equipment, weighs about 17,000 pounds. |

|

1921 Pawling & Harnischfeger Co.-Horizontal Boring, Drilling & Milling Machine

1921 Pawling & Harnischfeger Co.-Horizontal Boring, Drilling & Milling Machine

1921 Pawling & Harnischfeger Co.-Horizontal Boring, Drilling & Milling Machine

1921 Pawling & Harnischfeger Co.-Horizontal Boring, Drilling & Milling Machine

|

|