|

Title: |

1921 Article-Waltham Machine Works, Automatic Thread Milling Machine |

|

Source: |

Machinery, V28, Sep 1921, Pg 73 |

|

Insert Date: |

6/16/2016 8:03:29 PM |

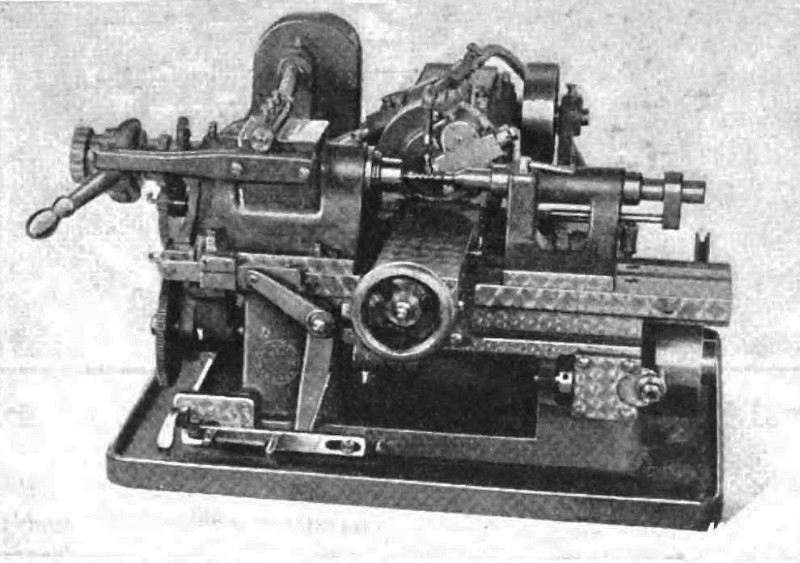

The Waltham Machine Works, Newton St., Waltham. Mass., are now manufacturing an automatic thread milling machine which is intended for manufacturing purposes and is so designed that it may be equipped for a large variety of work. After the work has been placed in position either on centers or in a chucking device, the machine is started by raising a lever at the left end. The feeding of the cutter into the work to the required depth, the milling of the thread, the withdrawal of the cutter after the required length has been milled, the returning of the cutter to the starting point, and the stopping of the machine are wholly automatic. These automatic features enable a number of machines to be handled on some kinds of work by one operator. With multiple threads the operation is continuous until all threads have been milled, so that for a triple thread the cutter would engage the work for its entire length, three times before the machine would stop.

The length of a thread cut by the machine corresponds to the amount of rise on the cam that controls the work-slide, and its pitch is governed by the relation between the gearing from the work-head to the camshaft, and the lead of the cam. The indexing for multiple threads is obtained by a fractional proportion in the gearing and as the work-head revolves continuously there is no backlash to cause inaccurate spacing. The maximum travel of the work-slide is 2 inches, and threads of this length or shorter may be milled. Adjustments enable the milling to be done either close to the work-spindle or in any position not more than 6 inches distant. The approximate locating of the cutter-slide relative to the work-head is obtained by moving the support of the cutter-slide along tongued ways, while the exact location is obtained by adjusting the work-slide cam-shoe attached to a slide at the front of the machine. An angular adjustment of 45 degrees each side of the horizontal is provided for the cutter-head. A special high-speed cutter-head is provided for brass work.

A single belt drives the entire mechanism with the exception of the oil-pump. This is separately driven and pumps oil from a reservoir in the base upon which the machine is mounted. The work-spindle is made of hardened steel; it has a spring collet and is equipped with a lever-closing attachment. The mechanism for automatically stopping the machine can be adjusted to function at the end of one cam revolution or after any predetermined number of revolutions necessary for the cutting of multiple threads. The machine can be modified for cutting helical gears. It may be installed either on a bench or a cabinet base. |

|

1921 Waltham Machine Works, Automatic Thread Milling Machine

1921 Waltham Machine Works, Automatic Thread Milling Machine

|

|