|

Title: |

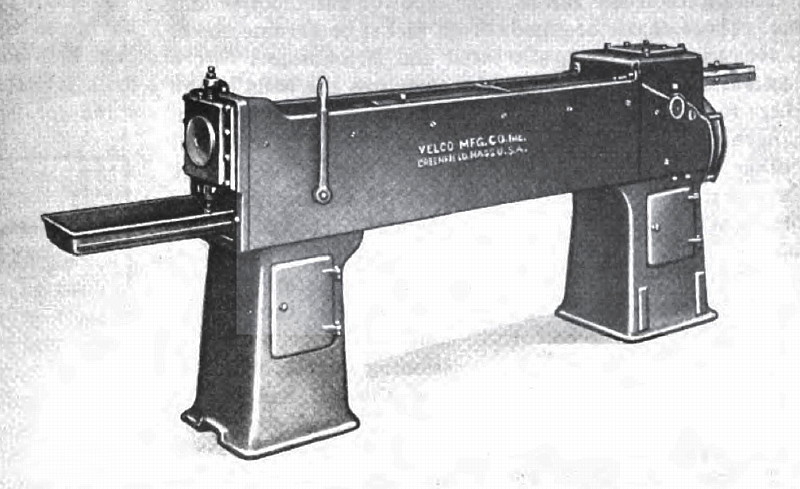

1921 Article-Velco Mfg. Co., Inc., #4 High-Speed Broaching Machine |

|

Source: |

Machinery V28, Sep 1921, pg. 75 |

|

Insert Date: |

6/16/2016 7:56:40 PM |

A heavy-duty high-speed broaching machine having several novel features has been developed by the Velco Mfg. Co., Inc., Greenfield, Mass. This machine has a cutting stroke speed of 15 feet per minute and a return stroke speed of 55 feet per minute. The broach holder is attached to a solid steel head and this is supported throughout its travel by bronze gibbed bearings sliding on steel ways. Power is applied to a rack that meshes with a pinion cut integral with a heavy shaft. The broach is attached to this rack so that the pull comes directly on the pitch line of the rack teeth. All vertical adjustments are made at the faceplate.

Stub gear teeth are provided on the rack and driving pinion. The teeth of the rack are on the underside, and the sides of the rack are guarded to protect the operator from injury. All other moving parts are completely enclosed. The rack is held in proper mesh with the pinion by means of rollers placed at the sides of the pinion and guide bars fastened to the sides of the rack, thus making a rolling contact on the pitch line. The pinion-shaft is driven through a phosphor-bronze worm-wheel and a hardened steel worm which runs in oil. The worm-shaft is provided with ball thrust and radial bearings.

The rapid return stroke is accomplished by means of an internal gear cut on the worm-wheel. This internal gear drives the return gear shaft, the return motion being applied through the driving pinion. The driving clutch is not operated during the cutting stroke and so acts as a positive coupling. All parts are protected from shock due to the operation of a positive clutch under load. |

|

1921 Velco Mfg. Co., Inc., #4 High-Speed Broaching Machine

1921 Velco Mfg. Co., Inc., #4 High-Speed Broaching Machine

|

|