|

Title: |

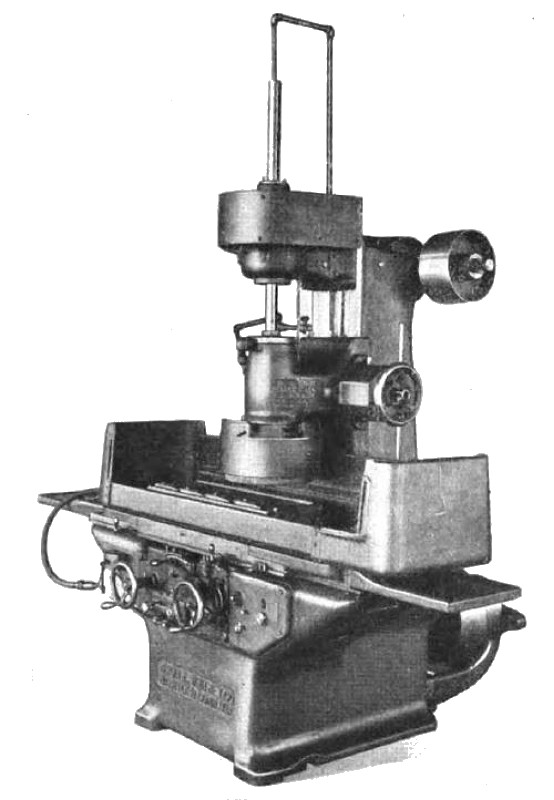

1921 Article-Pratt & Whitney Co., 14 inch Vertical Surface Grinding Machine |

|

Source: |

Machinery, V28, Oct 1921, pg. 158 |

|

Insert Date: |

6/13/2016 1:43:18 PM |

The 14-inch vertical surface grinding machine of the movable platen type built by the Pratt & Whitney Co., Hartford. Conn., has had a number of new features incorporated in its design. The ball bearing mounting of the spindle has been completely redesigned, the weight of the wheel unit now being carried on springs set against the upper bearings. This arrangement provides an automatic compensation for wear. The upper section of the mounting is lubricated by oil dripping from regulation oilers through the bearing, and falling into whirling cups which throw it back into the bearing by centrifugal force. In the lower section oil is poured into a large reservoir from which it flows into the upper bearing and runs along the spindle to the lower hearing. The grinding wheel faceplate acts as a retainer, and ribs in this plate continually throw the oil up into the hearing.

The table drive has been strengthened by the use of hardened shafts, gears, and clutches, and is amply lubricated from sight-feed oilers on the front of the case. The entire drive-shaft unit is easily removed through the provision of split bearings. Hand operation of the table has been simplified by the use of a sliding gear on the hand-wheel shaft in place of a clutch. Smoother reversing of the table is accomplished by means of a dwell in the pinion drive which permits the table to come to a stop before reversal takes place. This eliminates shock and protects the clutch mechanism. The idlers over which the main driving belt runs have been equipped with roller bearings which are lubricated by large grease cups in the ends of the stationary shaft, and the spindle driving pulley is surrounded by a heavy sheet-metal guard.

A series of baffle plates are cast integral with the tank, and these plates are provided with openings alternately at the top and bottom. The solution flows over and under these plates in such a manner that a clean solution is obtained in the last compartment from which it is drawn off by the pump. The motor drive has been improved by making the motor base adjustable so that the driving belt may be correctly adjusted relative to the steps of the driving cone. The drive for the rotary tilting chuck is now equipped with a flexible coupling, which facilitates the mounting of the unit and aligning of the drive shaft. |

|

1921 Pratt & Whitney Co., 14 inch Vertical Surface Grinding Machine

1921 Pratt & Whitney Co., 14 inch Vertical Surface Grinding Machine

|

|