|

Title: |

1903 Article-Fairbanks, E. & T., & Co., Power Hammer |

|

Source: |

Modern Machinery, V13, May 1903, pg. 162 |

|

Insert Date: |

3/2/2016 7:22:53 PM |

Special Pattern Hammer

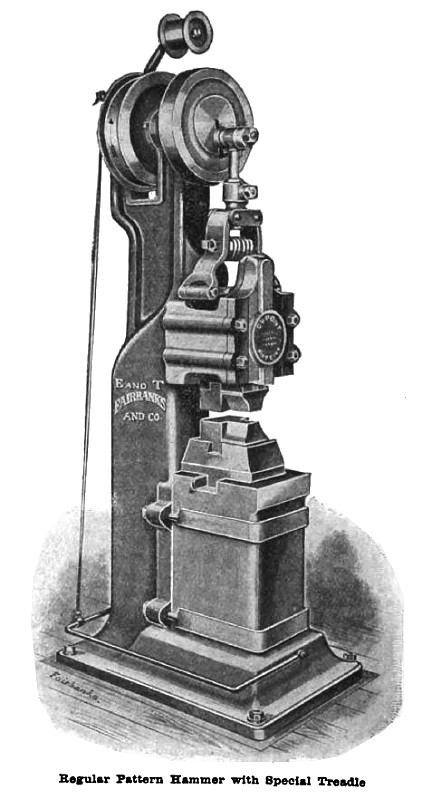

The Power Hammer represented in the accompanying engraving is one made by E. and T. Fairbanks and Company of St. Johnsbury, Vermont, and is considered to be a machine tool of the highest class and of important usefulness. The manufacturers make seven different sizes, among which we may name No. 1, a Regular Pattern Hammer; No. 2, a Regular Pattern Hammer with special treadle, and No. 3, Special Pattern Hammer, the one represented here, designed for work where it is necessary to work up to a shoulder, as in drawing fork tines, T irons, and a variety of carriage and agricultural work. Special attention is called to the anvil which is made of steel, resting on a cast-iron base separate from the frame of the hammer.

The hammer is operated by an adjustable crank, the crankpin sliding in a groove in the crank plate, allowing the operator to lengthen or shorten the stroke at will. Motion is applied to the head or ram by means of a connecting rod sliding in a sleeve or collar supplied with a large set screw, or as in the larger sizes, a clamp to hold the rod in position,' and to this sleeve are hinged two side arms, these in turn being directly connected to the ram by metal links. By the use of a steel spiral spring properly adjusted between these arms, the force and weight of the blow are many times multiplied, but with an elasticity that removes all danger of breakage, and, at the same time, the jar is so thoroughly cushioned that it is not noticeable in the machine when the blow is struck. The head strikes a quick, sharp blow, at the rate of 250 to 500 blows per minute, according to the size of the machine, and instantly gets away from the work thereby avoiding any chilling of the stock.

The entire working parts of the Hammer are at the top in full view of the operator, and every part is readily accessible being easily operated by inexperienced men. Raising or lowering the Hammer is accomplished by loosening one bolt, and when at the required place tightening it again. |

|

1903 Fairbanks, E. & T., & Co., Power Hammer

1903 Fairbanks, E. & T., & Co., Power Hammer

|

|