|

Title: |

1903 Article-Pratt & Whitney Co., Automatic Internal Cup Grinder |

|

Source: |

Emery Grinding Machinery, 1903, pgs. 77 |

|

Insert Date: |

11/20/2015 8:56:39 PM |

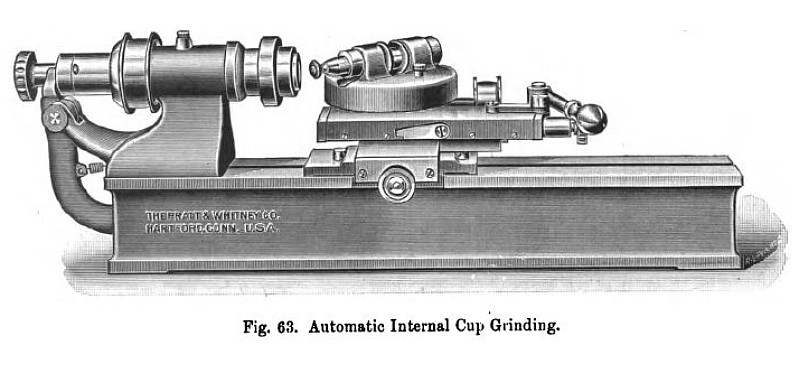

CUP AND CONE GRINDING MACHINES.

These machines are specially designed for grinding the ball-race of bicycle cups and cones, and the outside of cups. Various styles or combinations are made in building up the parts of the machine for dealing with straight and angular grinding, or for automatically grinding to a predetermined curve, the operation being performed either before or after the cups and cones are placed in the hub or on the axle.

The machines figured are manufactured by the Pratt & Whitney Co., Hartford, Connecticut. One of their special features is, that the collet or chuck for inside work is a step chuck, split in three places, and closed by means of springs in an ordinary spring barrel. For outside work an expansion chuck is used; at one end of the headstock is pivoted a lever which extends under the bed, and is there connected by a wire cord to a wooden treadle secured to the floor by a hinge and screws. A pressure on the treadle by the foot causes the drawback chuck to open for inserting or taking out the cups, the lever also acting as a brake for stopping the spindle immediately.

Removing the pressure from the treadle permits the chuck to close, thus clamping the cup to be ground. The belt for driving the machine is shifted by means of a connection with the same treadle that actuates the opening and closing chuck mechanism in the head. The countershaft for driving the machine is either attached to the ceiling or to the wall, according to circumstances. One combination of the machine (fig. 63) consists of bed, headstock and countershaft; it is fitted with an inside form grinding attachment for automatically grinding the inside of cups to any of the ordinary forms. The grinding attachment consists of an upper and a lower slide; the lower or cross slide is attached to the bed by means of two special clamps, and has an adjusting screw by which the diameter to be ground can be regulated. The hand lever on the upper slide is used to move the emery wheel from the work. The emery wheel travels in a predetermined path, and is controlled by a cam or form located under the wheel head; this form can be made for grinding surfaces at right angles almost to a sharp corner or a curve, and with its two tangential surfaces tangent of any radius up to one half inch.

The spindle of this attachment has a special form of bearing, consisting of separate balls running in suitable ground tracks; a speed of 30,000 revolutions per minute can be maintained without heating.

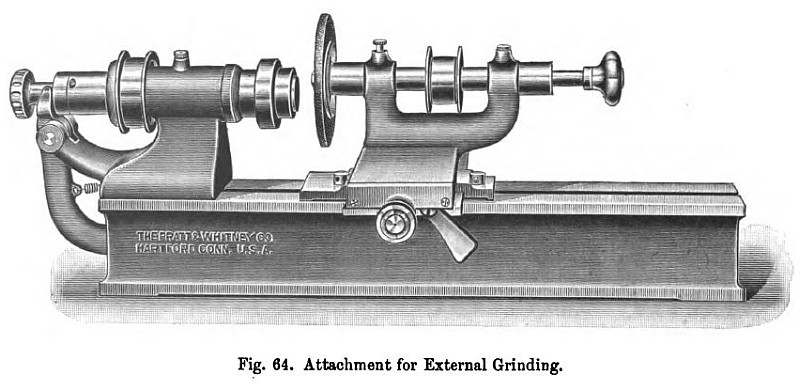

Fig. 64 is another combination of the machine. It consists of bed, headstock and countershaft, as in the machine shown in fig. 63, but it is fitted with an outside grinding attachment for grinding the outside straight, and angular surfaces of cups and cones; it will not grind curves. This attachment is secured to the bed by means of suitable clamps, and has an adjusting screw by which the diameter to be ground can be regulated. The hardened tool-steel spindle f inch diameter runs in hardened bearings, and carries an 8 inch emery wheel worked by hand. |

|

1903 Pratt & Whitney Co., Automatic Internal Cup Grinder

1903 Pratt & Whitney Co., Automatic Internal Cup Grinder

1903 Pratt & Whitney Co., Attachment for External Grinding

1903 Pratt & Whitney Co., Attachment for External Grinding

|

|