|

Title: |

1906 Article-J. A. Fay & Egan Co., #4 Triple Drum Sander |

|

Source: |

Wood Craft, Jan 1906, pg. 176 |

|

Insert Date: |

10/4/2015 4:51:15 PM |

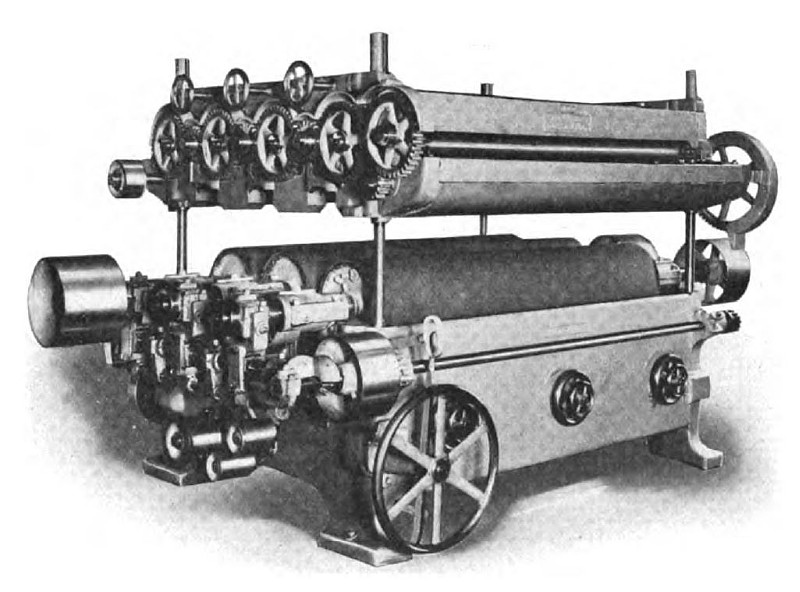

Fay & Egan Co.'s Sander

This machine sandpapers planed surfaces of material for furniture, pianos, organs, wagons and cars; for panels, doors, or any class of work in readiness for varnishing or painting.

It is a heavy and substantial machine, combining the latest improvements which an extensive experience could suggest. Made in eight sizes to work up to 30, 36. 42, 48, 54, 60, 66 and 80 inches wide-.

The steel drums are three in number, upon which the sandpaper is placed and graded according to the work to be done. The first drum carries a coarse grade of paper, the second drum a fine grade for smoothing, and the third drum a still finer grade for giving the material the polished surface. Each drum has an oscillating motion across the material to prevent the formation of lines. They are equipped with a device for placing the sandpaper about them and giving it the proper tension in the shortest time. The drum-shafts are steel, inches diameter, and revolve in heavy bearings, gibbed to the sides, and with adjustments to lift both ends of the drums at once, or either end separately for alignment. The drums can be easily removed by raising the entire roller and bed frame, which opens a space directly over them sufficient to lift them out and over their bearings. This raising device is operated either automatically by a system of gearing or by the large hand-wheel by which the screws at the four corners of the machine are turned, the screws resting on ball bearings. The screws adjusting the upper feed roll frame are all fitted with improved nuts taking up wear of the screws and insuring the gage of work. The adjustment of the drums for the difference in heavier or lighter cutting is done by the movement of the different hand-wheels at the end of the machine.

The feed-rolls are eight in number, four above and four below the platen, driven by a train of heavy expansion gearing. The upper and lower sets open to receive material 8 inches thick. The lower rollers are placed one on each side of each drum, each roller is located in a separate bed-plate adjustable with the roller, the roller having a separate adjustment from the bed-plate. Each bed-plate can be set to gage the amount of cut to each drum, or all the bed-plates can be set in line and the drums set to the cut desired above this line. The upper rolls are mounted in a frame over the corresponding lower rolls. The pressure rolls are three in number, one over each drum to hold the material firmly to them, and are separately adjustable by the hand-wheels shown at the side. The feed is governed by a double belt-tightener operated by a hand-lever.

A brush attachment cleans the material as it passes from the machine. The countershaft can be placed in any position that may be desired. A shop number is attached to each machine and a number on each casting by which they can be identified, and should be mentioned in ordering supplies. This sander is the No. 4 triple drum, eight roll, power feed machine and is made by the J. A. Fay & Egan Co. of Cincinnati. |

|

1906 J. A. Fay & Egan Co., #4 Triple Drum Sander

1906 J. A. Fay & Egan Co., #4 Triple Drum Sander

|

|