|

Title: |

1905 Article-Cordesman Machine Co., Planer, Matcher & Moulder |

|

Source: |

Wood Craft, Dec 1905, pg. 134 |

|

Insert Date: |

10/1/2015 10:01:59 PM |

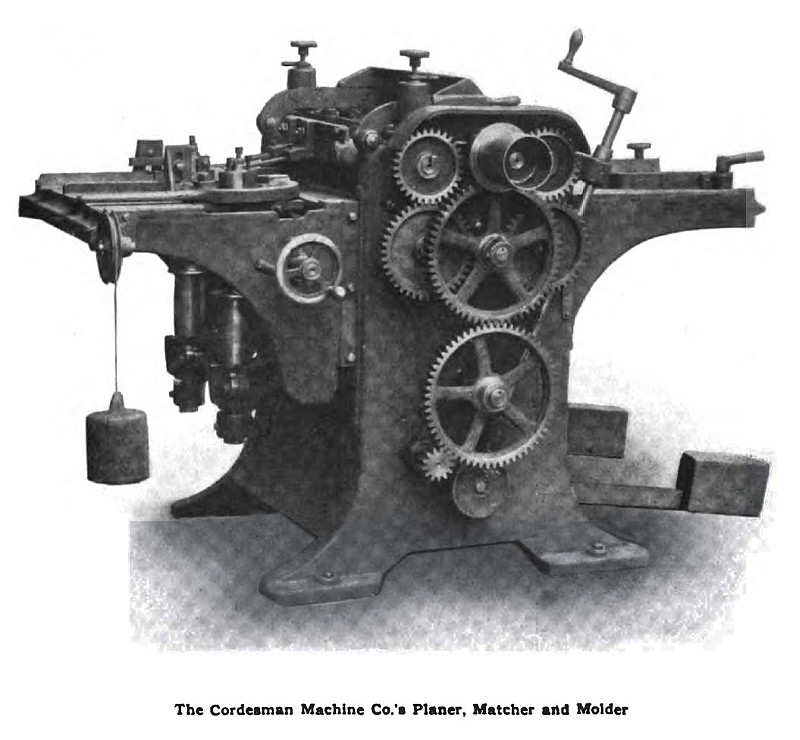

A New Planer, Matcher and Molder

The Cordesman Machine Co. of Cincinnati, has brought out a machine intended for small planing and sawmills to meet the requirements of these and other woodworking shops having limited room and power, where a small combination machine is needed for planing top side and dressing two edges of flooring, ceiling, wainscoting, partition, casing, siding and other moldings. A great variety of work is possible with this new tool and special attention has been given to its weight, belt power, size of journals, range, adjustable features, etc.

The frame is of generous proportions, thoroughly ribbed throughout and the metal distributed in a manner insuring strength and rigidity. The table is very deep—fully 14 inches—and made in one piece, its top plate in the rough is over one inch thick with bracer arches on under side. It is fitted to the frame by the special method adopted by the firm that of four ways all far apart and very deep, provided with dovetail gibs and screws in such a manner that the mere turn of the gib screw locks the table to the frame as though both were cast in one. This, the experienced operator will commend as a valuable feature, the table remains level, cannot sag as the lumber is placed on the front or as it passes over the out-feed end. The table may be adjusted while the operator is in a standing position, a scale in plain view telling the space under the cutter head. The cylinder is made of hammered crucible high carbon steel, has long self-oiling bearings, is four-sided with two sides slotted, carries molding, beading and siding knives, without removal of surfacing cutters whose position therefore is not disturbed and is made for two belts.

The chip-breaker hood before the top cutter head and the pressure bar after the latter, are adjustable in two ways, vertically and horizontally, therefore are self-adjusting to variations in thickness of stock and may also be spread to clear for molding cutters, or brought close to knives for critically smooth work as well as for short stock.

The feed work is of simple construction and may be instantly stopped and started. All the rolls are made of forged steel three inches in diameter. The upper rolls are powerfully geared. The in feeding roll is fluted and given pressure by weight levers; the out feeding roll has spring tension, controlled by hand wheels in close reach of the operator. The lower rolls are also adjustable, and their adjusting screws are of easy access.

The matcher spindles are made of refined machinery steel and revolve in long split boxes lined with genuine Babbitt metal; the caps have large oil reservoirs cast in them. Both upper and lower spindle-boxes are connected by webs and gibbed to two horizontal bearings securely fastened to table. Owing to the peculiar construction belt strain does not affect the cap side of boxes and provision is made for taking up all wear. The matcher spindles with heads move up and down with the table; they have a lateral adjustment for the different widths of beards, and are provided with patent chip-breaking device to prevent slivering and breaking out of knotty and cross-grained lumber. The matcher heads are made out of composition gun metal, and furnished with the best tool steel milled bits. The matcher heads and their guides, etc., may be readily removed for wide surfacing.

This machine possesses many other useful features peculiar to the similar machines of same make, among them being the arrangement of matcher clips, guides and enlarged pocket around side heads, all of which are recommended in the manufacture of sprung or crown molds and similar work requiring the large projecting cutters used in making bevel side cuts and deep molded edges. |

|

1905 Cordesman Machine Co., Planer, Matcher & Moulder

1905 Cordesman Machine Co., Planer, Matcher & Moulder

|

|