|

Title: |

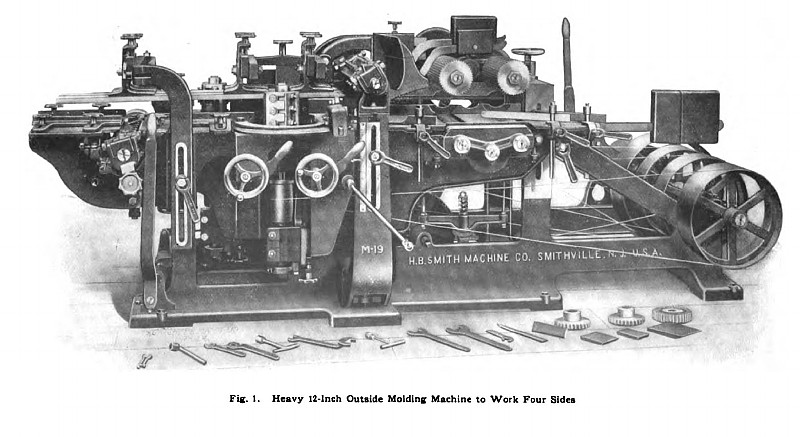

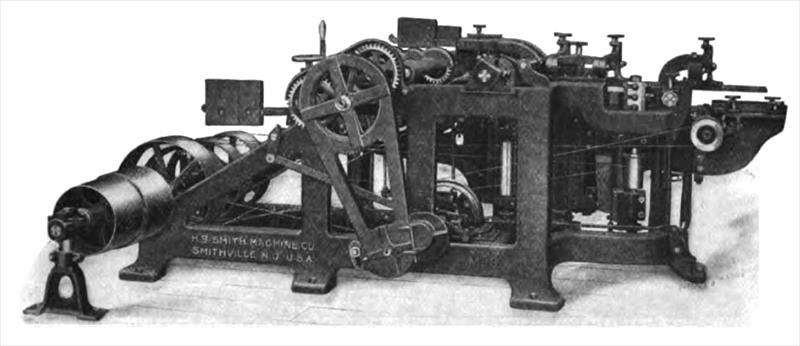

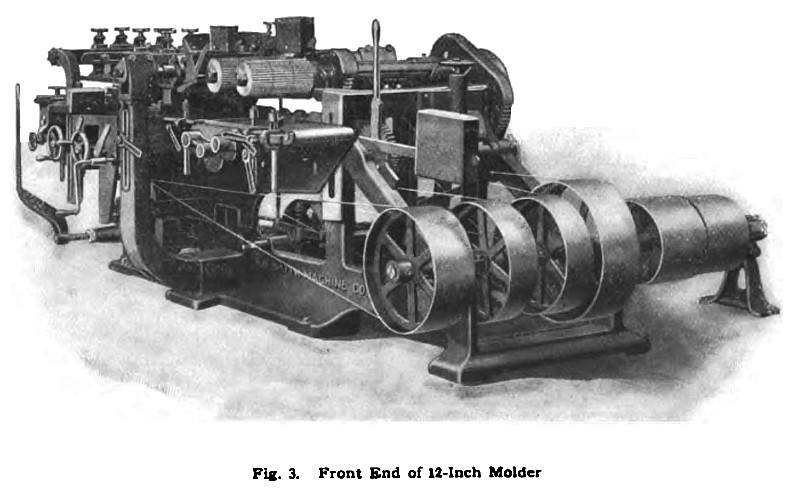

1905 Article-H. B. Smith Machine Co., #M-19 12" Planer Matcher |

|

Source: |

Wood Craft, Oct 1905, pgs. 52 & 53 |

|

Insert Date: |

9/26/2015 12:51:44 PM |

Extra Heavy 12-Inch Molder to Work Four Sides

The extra heavy 12-inch molding machine will work moldings, flooring, ceiling and sheathing as wide as 12 inches, and the side heads will work as thick as 5 inches, hence the machine will work all four sides of material within these dimensions. It will also plane two sides of timbers not exceeding 12 x 12 inches and any length; therefore this machine is particularly well adapted for car shops, large molding mills, and for working all kinds of hard wood.

The frame is one massive casting, 115 inches long by 45 inches wide on base, 31 inches wide on top and 40 inches high, giving ample room for long and wide belts, with substantial support to all the working parts, and allows convenient access to the inside vertical head.

The table is very heavy and wide, will lower to 12 inches for the deeper class of work (heavy door rails, etc.). The ways arc adjustably gibbed and the screw which doe's the raising and lowering rests on ball bearings, and is operated from the front. Three powerful clamp-screws hold the table firmly in position when adjusted, which makes the machine practically as rigid as an inside molder.

The feed has four 6-inch feed rolls made in three sections, all strongly driven and expansively geared like a planer, and controlled by levers both front and rear which operate a friction clutch that drives the new gearing through a roller chain; hence the feed is positive as well as powerful. The weighting of the rolls is done in a superior manner, a spring intervening between the weight-lever and rolls to minimize any shocks in starting heavy cuts. Raising the weight-lever lifts the feed rolls for withdrawing stock and they may be retained by the prop in a lifted position if desired. The upper rolls have parallel lift and adjust to change the angle with face of machine. The feed shafts are 2 inches in diameter, and the rates of feed are 11, 18, 29 and 46 feet a minute, by shifting belt and changing one gear, and by one gear more 26 and 36 feet a minute can be added.

The spindles are all made of high carbon steel; the main arbor is 2¼ inches, with the three patent clamp bearings aggregating 25 inches in length, 2 inches for the head and 1½ inches for outside bearing, driven by an 8-inch belt. The under-head has 2-inch journals with 17 inches of patent clamp bearings and is driven by a 5 inch belt. The side spindles are 1¾ inches in the bearings and inches for heads. They are also fitted with patent clamp bearings and an adjustable step. The horizontal spindles have longitudinal adjustment, and the upper mandrel is provided with a belt tightener for regulating the tension of the belt.

The patent clamp boxes in which all the cutter spindles run, are an improved form of the White patent, and can be adjusted to the one-thousandth part of an inch and the caps clamped as firmly as if bolted. These bearings are equally important for the vertical spindles, in which case the pull of the belt is against the headstocks. The outside support to main spindle has vertical adjustment.

The side heads or their stocks are attached to the table and adjust and lock from the front. The inside head is perfectly accessible owing to the new style of framing, and the outside head has a weighted chip-breaker. Both of the side heads have lateral, vertical and angular adjustments.

The cutter heads furnished are made of hammered high carbon steel, 4 slotted and lipped, and all of the same cutting circle (6 inches) admitting of an interchange of cutters on the different heads.

The under cutter head has adjustment to regulate the depth of cut, and the end of bed after the under head has adjustment to fit the cut as well as being raised and lowered with the head when it is once set to the cutters. It is right for a light or heavy cut, when set for the cutters in use, without further attention.

The chip-breaker and pressure-bars are all adjustable, and the pressure feet may be set at angles to suit the work. The pressure-bars over the under cutter head have an outside bearing or support which by a clamp-bolt is held firmly to the table and frame. All bars and chip-breakers are readily removable for sharpening cutters. The table beyond the under head drops down for this purpose.

All the screws and clamps have hand wheels, handles or stationary wrenches, and a crank for raising and lowering table, and to back the feed. The spring posts are held solidly by an improved cast steel clamp. The loose pulley on the countershaft is made the same size as the tight one unless otherwise ordered, and has patent self-oiling bush. All pulleys are of generous size and balanced in the plane of rotation to run true at any speed.

This machine is made by the H. B. Smith Machine Co., Smithville, N. J. |

|

1905 H. B. Smith Machine Co., #M-19 12" Planer Matcher

1905 H. B. Smith Machine Co., #M-19 12" Planer Matcher

1905 H. B. Smith Machine Co., #M-19 12" Planer Matcher (Rear View)

1905 H. B. Smith Machine Co., #M-19 12" Planer Matcher (Rear View)

1905 H. B. Smith Machine Co., #M-19 12" Planer Matcher (Front View)

1905 H. B. Smith Machine Co., #M-19 12" Planer Matcher (Front View)

|

|