|

Title: |

1905 Article-American Wood Working Machinery Co., American #0 Rip-Saw Table |

|

Source: |

Wood Craft, Oct 1905, pgs. 51 & 52 |

|

Insert Date: |

9/25/2015 9:48:36 PM |

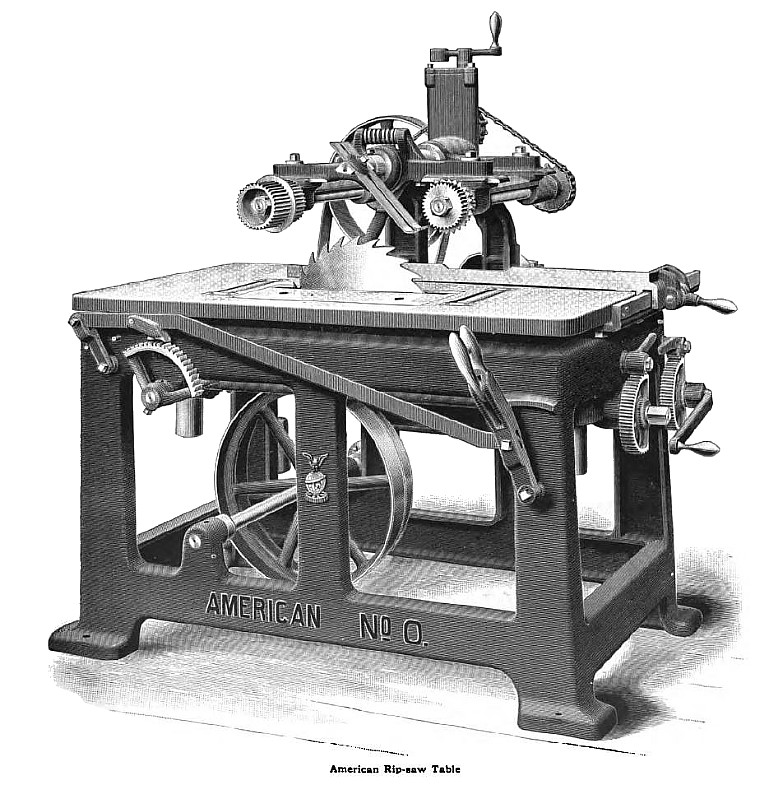

American Rip-saw Table

In its general outline this No. 0 machine is similar to Nos. 1 and 2 of the same make. It differs slightly in construction and is somewhat lighter in weight, but it is strong and rigid. For the ripping of any grade of lumber up to 15 inches wide and 6 inches thick it is especially adapted and is strongly recommended for use in general woodworking shops on the small sizes of stock.

The frame is heavy, and internally ribbed in substantial style. The table is 26½ inches wide by 46½ inches long, and is provided with two adjustable idler rolls and an iron throat plate, so that two or more saws can be used at the same time. The extreme distance between the saws is 3¼ inches. The rise and fall of the table is 4 inches. This is regulated by the first right-hand crank, and is held firmly in position by a pawl engaging with the ratchet wheel. One movement of the crank raises the table to the desired height. The table is fitted in front with an index plate showing the width to be ripped. The distance between the saw and guide is 15 inches, but by placing the saw against the outside collar next to the nut 18¼ inches in width can be ripped.

An improved self-locking gage is furnished with each machine. By simply raising the handle or the lever attached to it (as shown in the cut, the gage is instantly released and can be moved to any desired point on the scale or index plate, where it is securely held by the weight of the handle or lever when allowed to drop back into position.

The feed consists of a corrugated and spur feed roll in front, with a corrugated feed roll with spreader in the rear of the saw. These rolls are 4 inches in diameter. They are adjustable so that they can be set up close to a 10-inch saw or can be expanded to take in a 16-inch saw. All feeding adjustments are fitted to the main sliding headstock, which rises and falls parallel with the table by the use of the second right-hand crank on the front of the machine. One movement of this crank will raise the rolls to the desired height.

The rolls are driven by belt, chain and sprocket wheel. Their shafts run in connected boxes fitted to two swinging housings having independent lift.

This machine is a recent production of the American Wood Working Machinery Co. of New York. |

|

1905 American Wood Working Machinery Co., American #0 Rip-Saw Table

1905 American Wood Working Machinery Co., American #0 Rip-Saw Table

1905 American Wood Working Machinery Co., American #0 Rip-Saw Table (Rear View)

1905 American Wood Working Machinery Co., American #0 Rip-Saw Table (Rear View)

|

|